________________________________________________________________________________

1006 Perkins Motor - Spacer (MF 8100/8200)

Removing and refitting the spacer

8210, 8220, 8240, 8250 MF Tractors may be fitted with either a Heavy

gearbox or a Powershift gearbox. This section is limited to parts

concerning the Heavy

gearbox. The Heavy gearbox comprises two casings: the main housing which

encloses the pinions, the shafts and the input unit, the spacer,

providing the

connection with the 1006d engine.

Split the tractor between the 1006 Perkins Motor and gearbox.

Disassemble the four screws (dia. 10 mm) on each front Silent Block on

the right- and left-hand

engine bearers.

If the side fuel tank was not removed during the separation operation,

drain the gas-oil and remove the footstep in question then the fuel

tank.

Raise and block the cab. Remove the cab supports (right and left) and

any adjacent parts likely to obstruct removal of the spacer. Drain the

gearbox. Install

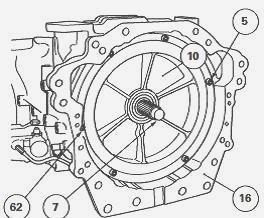

protector, P/N 3378012M2 on main shaft (7) (Fig1).

Remove screws (5) (62) in order to facilitate unsticking of closure disk

(10) (Fig1). Use the tapped holes and two screws of sufficient length to

extract and

maintain the disk before removing it. Scrap seal (8) (Fig6).

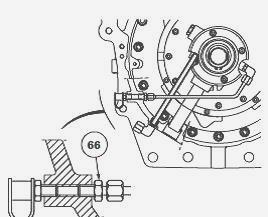

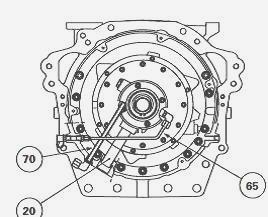

Remove lube tube (17) from the engine clutch located under the gearbox

between spacer (16) and intermediate housing (19) (Fig4). Remove tubes

(20) (65) (70)

and union (66) (Figs2 - 3).

Remove the clutch using locally procured tooling.

Removing the spacer - The cab inner floor contains an access door. If

necessary, use the latter for accessing the top screws securing the

spacer to the

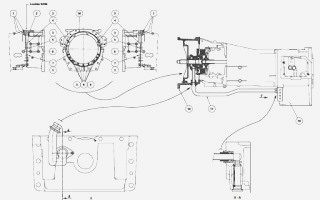

gearbox. Remove screws (1) (4) (5) (7) and nuts (8) on spacer (16).

Remove washers (3). Assisted by an operator, unstick and remove the

spacer. If

necessary, extract studs (9) from the gearbox housing.

Refitting - Clean the parts and replace any that are defective. Remove

all traces of old Loctite from the mating surfaces. Coat the mating face

of the spacer

(gearbox side) with Loctite 5206 or equivalent. Ensure presence of

locating pins (6) (Fig4). Studs (9) are smeared with Loctite 270 and

locked into the gearbox.

Refit the 8210, 8220, 8240, 8250 MF spacer. Coat the screws and nuts

with Loctite 270 and torque to following values: screws (1) and nuts

(2): 150 - 200 Nm,screws (4) (5) (7) and nuts (8): 100 - 130 Nm. Coat union (66) with

Loctite 542 then screw onto the spacer (Fig2). Refit the clutch and

tubes.

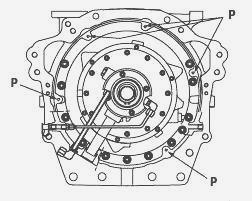

Ensure the presence of centring pins on the closure disk, and shims on

the clutch assembly. Replace O’rings (8) (Fig6). Coat surrounds P of the

tapped holes

with Loctite 5206. (Fig5).

Grease the lip of the seal. Fit the shaft with the protector used during

disassembly. Screw two guide studs in opposing locations on the spacer,

and reinstall

closure disk (10) and finger (63) in the slot in pump body (12) (Fig6).

Install long screws (62) in the same holes as those provided for the

centring pins. Install

screws (5) (Fig. 1). Torque all screws to 25 - 35 Nm.

Refit the cab supports and any neighbouring parts that were removed.

Coat the screws for the supports with Loctite 270 then insert and torque

to 200-260 Nm. If

it was removed, reinstall the access door in the cab floor. Service the

oil in the sumps and check level on sight glass located on left of

centre housing.

Remove the props and set back the cab. Torque up the screws (10 mm) on

each Silent Block support to 50 - 70 Nm. Reassemble the tractor between

the

Perkins 1006 engine and gearbox. Check the following: leak tightness of

hydraulic connections and the mating face; operation of the engine

clutch.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader