________________________________________________________________________________

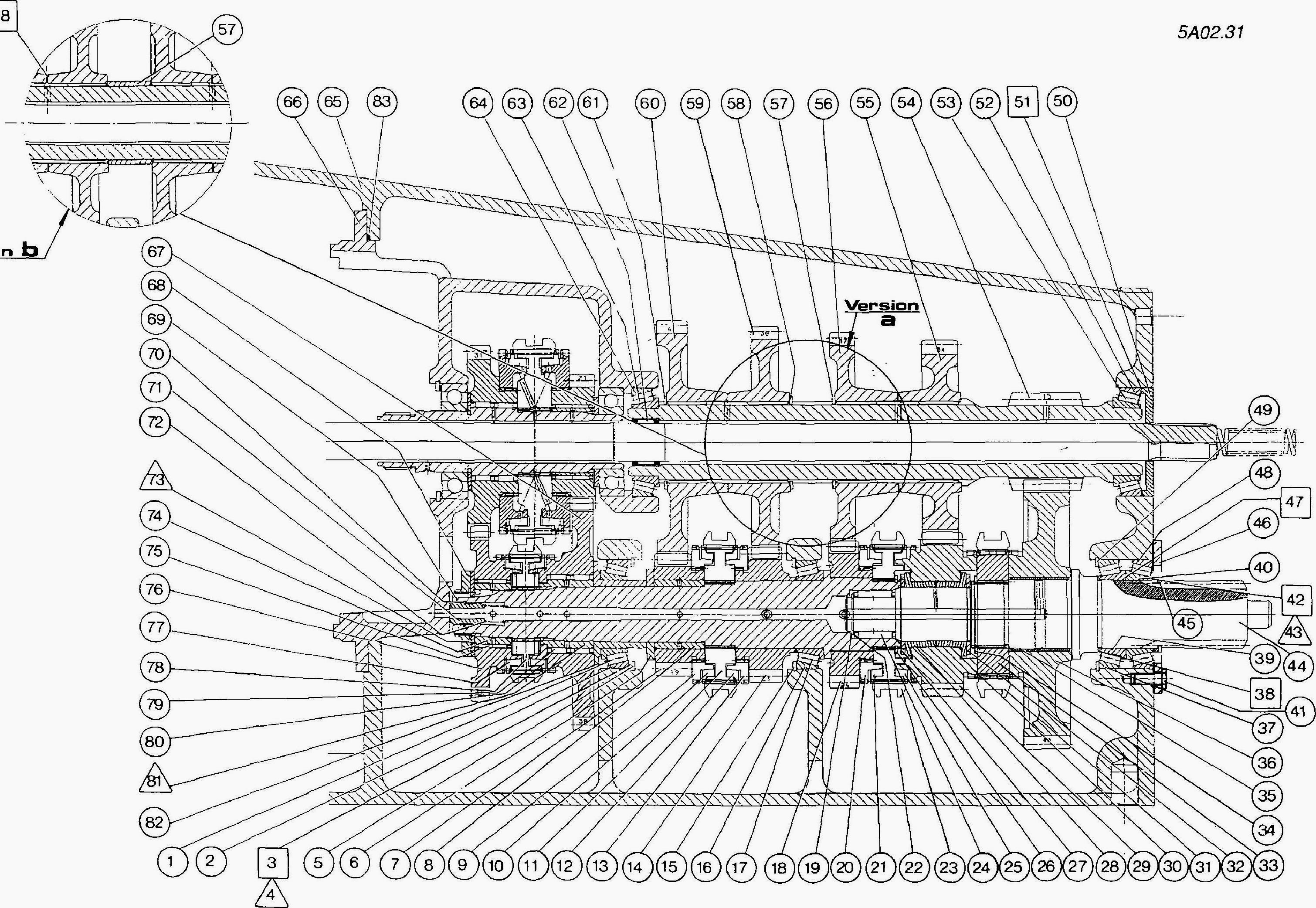

MF 3060, 3065 tractor Gearbox assembly

Removal and preparation

Fig.1

Split Massey Ferguson 3065, 3060, 3070, 3080 tractors between the

gearbox and the rear axle.

Place a sling under the gearbox (Fig.1). Split the tractor between the

gearbox and the engine or separate the gearbox from the engine. Remove

the PTO shaft.

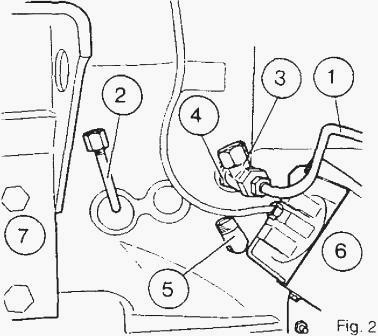

Fig.2

Remove:

- the PTO clutch hydraulic feed pipe,

- the engine clutch slave cylinder supply pipe,

- the T-piece and 1.5 bar valve,

- the 90; oil return pipe connection,

- the Datatronic sensor and its bracket (ii fitted).

- the LH cab support

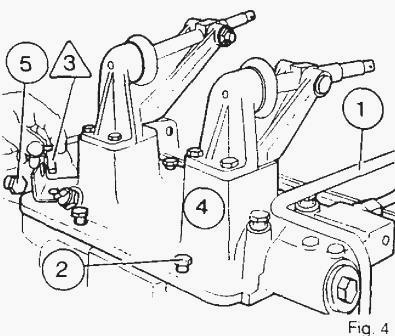

Lay the gearbox on its LH side and lift it on to a suitable stand or

work bench. Remove the A/B range (4x4 gearbox) feed pipe (1) (17 bar)

(Fig.4).

Remove the bolts (2). (Fig. 4). On gearboxes fitted with a creeper

range, remove the control cable bracket and mark the position of the

centring bolt 3.

Remove the cover (4) and bolt (5). (Fig. 4)

Fig. 4

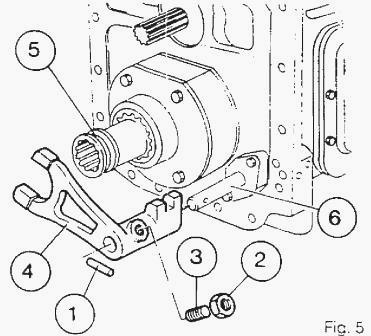

Shifter rail and forks - Removal:

Fig.5

Fig.6

- Gearbox fitted with creeper range. Remove the pin (1), the locknut

(2), the adjustable setscrew (3). the fork (4) with the sleeve (5).

(Fig.5)

- Remove me plugs (1). the sonngs (2) and locking plungers (3) from

forks (5) and (6) (Fig.6)

- Slacken the castellated nut using spanner 3615334 M01.

- Engage 4th gear (4x2 gearbox) or 3rd gear (MF 3060, 3065 tractor 4 x 4

gearbox).

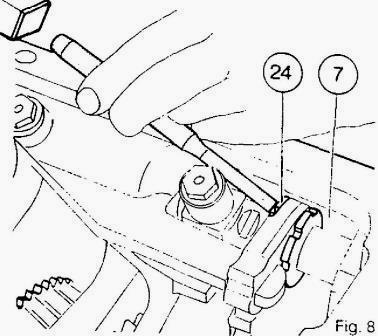

- Release the cone (24) on the shifter rail (7) using a bronze drift

(Fig.8).

- Remove the setscrew (8).

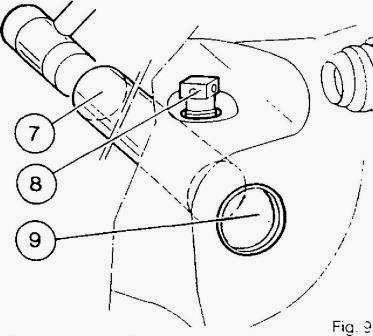

- Eject the plug forwards by tapping the end of the rail (7) (Fig. 9)

Remove:

- the bearing (15)

- the shifter rail (7) rearwards

- 1st and 2nd gear fork (5) and 3rd and 4th gear fork (6) the lock

assembly (25)

Disassemble:

- the castellated nut (21)

- the latch (22)

- the tapered bearing (23)

- the cone (24)

Remove:

- the screws (19)

- the piston (13)

- the High/Low range fork (20)

- the bolt and washer assembly (17) and the guide (18)

- the cylinder (10)

- Discard the seals (12) and (14) from piston (13) and the seal (11)

from the cylinder (10).

- The A/B fork (4) stays in the housing (MF 3060, 3065 tractor 4x4

gearbox).

Fig.8

Fig.9

Input shaft housing - Removal:

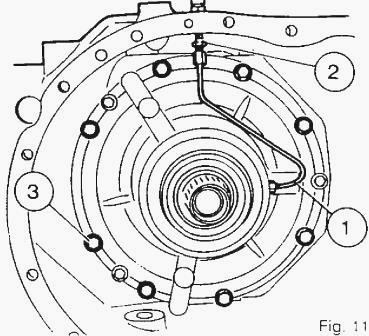

Fig. 11

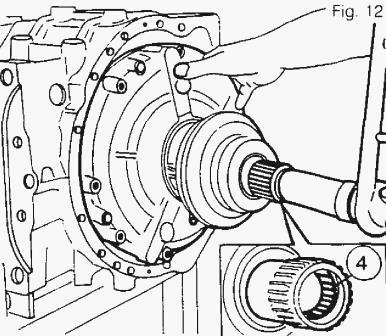

Fig. 12

- Immobilize the layshaft assembly using the locally made-up tool.

- Remove the drain pipe {1) from the clutch slave cylinder and the union

(2) on the housing (Fig. 11).

- Place a sling under the housing assembly, taking care to avoid

damaging the needle roller bearing (4) (Fig. 12).

- Remove the eight 10 mm diameter bolts (3) (Fig. 11). Note: It is not

necessary to remove the selector (5) (Fig. 13) in order to remove the

housing.

- Release and withdraw the housing assembly by tilting it to the left

(Fig 12). (Fig.13 and 14)

- Retrieve the locating dowel (8). Discard the oil seals (6) and (7).

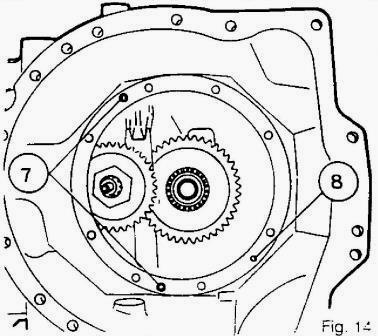

Fig. 13

Fig. 14

Layshaft - Disassembly:

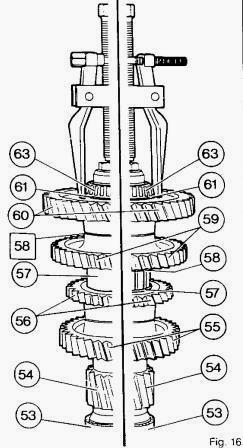

Fig.16

- Withdraw the layshaft complete,

- Remove the washer (50).

- Remove the shims [51].

- Remove the cup (52). Disassembly of shaft (54) (Fig.16).

- A new shaft fitting was introduced from serial number P345012 (version

b). MF 3065, 3060 Tractors prior to this number are fitted with version

a.

- Withdraw the taper roller bearings (53) and (63). Note: Keep the

bearings and cups in matched pairs for possible re-use.

- Remove the circlip (61).

- Remove 1st gear (60) and 2nd gear (59).

- Remove 1st gear (60). the shims [58] and 2nd gear (59).

- Remove circlips (58) and (57) (Fig. 16). b) Remove spacer (57)

- Remove 4th gear (56) (4x2 gearbox) and 3rd gear (55) (4x2 gearbox)

- Remove 3rd gear (56) (4x4 gearbox) and 4th gear (55) (4x4 gearbox).

- Drift out the needle roller bearing (62) (Fig. 17) and discard it.

Fig.17

MF 3060, 3065 tractor Creeper gearbox

Removal:

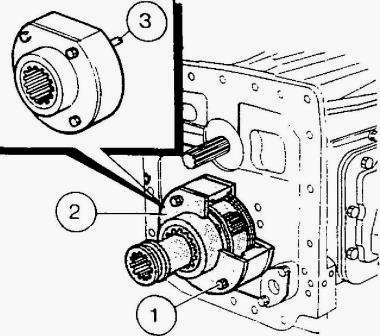

Fig.18

Fig.19

Remove the bolts (1).

Remove the creeper gearbox assembly (2). The locating dowels (3) are

held in the gearbox.

Output shaft - Disassembly:

- If the tractor is fitted with a creeper gearbox, see above.

- Remove the 3 bolts (41),

- Remove the lock plate (46).

- Remove the bearing cue (48).

- Keep the bearings and cups in pairs for possible re-use.

- Remove the circlip (45).

- Remove the spacer 43 and shims [42].

- Remove the taper roller bearing (40).

- Where shims have had to be inserted between bearings, remove the shim

adjuster(s) [47]

- Remove the roller bearing (39).

- Remove the shims [38],

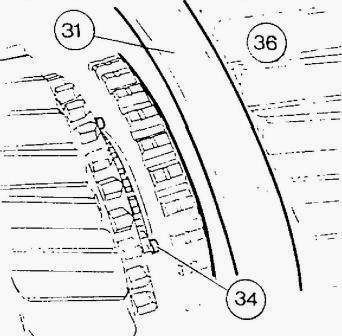

- Engage the High/Low range coupler (31) (Fig. 19) on me Low range

pinion (36)

- Withdraw the shaft (44) rearwards.

- Remove the circlip (34) using tool MF 460 and discard it (Fig. 19).

- Remove the shaft,

- Through the inspection panel in the selector rail mechanism cover,

withdraw: the hub (33) and its coupler, the gear (29) (3rd gear 4x2

gearbox and 4th gear 4x4

gearbox), the synchromesh cup (25). the two thrust washers (32)-{27) and

the Low range gear (36).

- Remove the cup (37).

- Remove the circlip (49).

- Remove the circlip (19). the washer (22) and the needle roller bearing

(24).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader