________________________________________________________________________________

Massey Ferguson 3080, 3070 Gearbox Mainshaft

Mainshaft Disassembly Massey Ferguson 3070,

3060, 3065, 3080 tractors 4x2 gearbox:

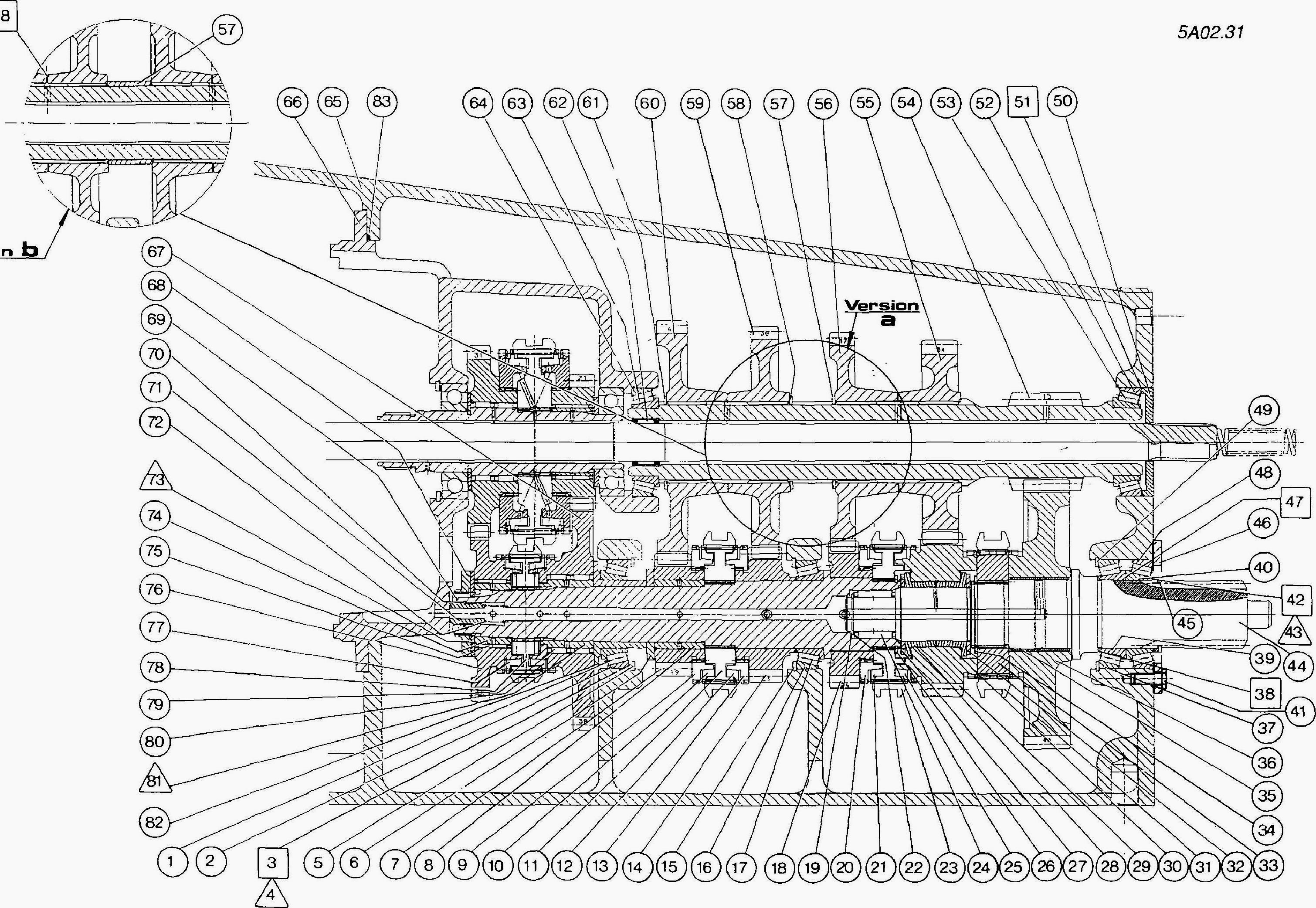

Fig.1

- Remove the circlip (26).

- Remove 3rd and 4th gear synchromesh (23). Mark the direction of

fitting.

- Remove the synchromesh cup (21)

- Remove the synchromesh cone (20) and the gear (18)

- Position MF 458 locking tool and the locally manufactured retainer

sleeve for the mainshaft (69).

- Remove the oil feed pipe (71) and spring (72).

- Unlock the nut (68) and slacken u using tool 3376805 Ml.

- Remove the input shaft gear (67) and cone (1).

- Remove the washer (6).

- Remove tool MF 458 and the sleeve.

- Withdraw the shaft from the housing rearwards regaining 1st and 2nd

gear train in place.

- From inside the housing remove, in the following order. 2nd gear (14),

cone (13), 2nd gear synchromesh cup (12), 1st and 2nd synchromesh (11),

cone

(9),synchromesh cup (10), 1st gear (7) and its bush (8).

- Withdraw the bearing cups (16) and (2).

- Remove the shims [3], the shim 4 and circlips (15) and (5).

- Remove the bearing cone (17) and circlip (70) from the shaft.

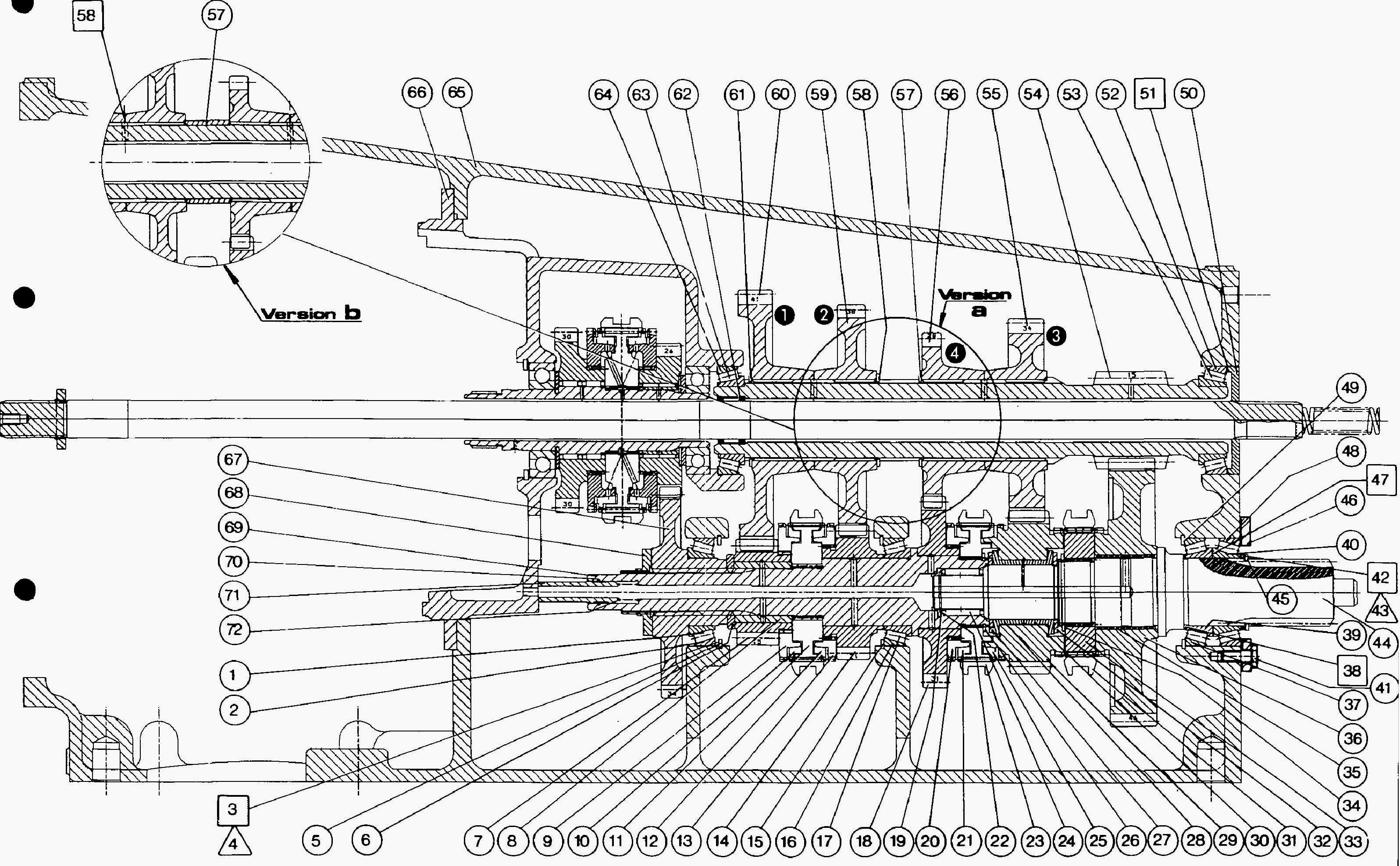

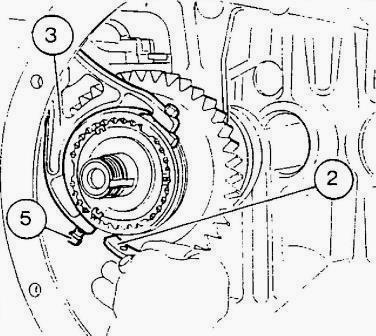

Fig.2

Mainshaft Disassembly Massey Ferguson 3080, 3070 4x4 gearbox:

Fig.25

- Remove the lock from the nut (68) and slacken the nut using spanner MF

456.

- A new A/B range synchromesh assembly fitted with sintered cone rings

was introduced from the following tractor serial numbers: 40 kph

tractors: P089036/30 kphtractors: P297030.

- Remove the spur washer /73V B gear (76) with the needle rotter bearing

(75) and bush (74). Remove the fork.

- Withdraw the A gear (67) with the double needle roller bearing (79)

and the bush 81.

- Remove the sleeve (82) and the bearing cone (1).

- Remove the 1st and 2nd gear tram complete (Fig.25).

- The Massey Ferguson 3070, 3080 gearbox housing must be clean and free

from swarf.

- Mating laces must be scraped clean,

- Use a jet of compressed air to check that all the hydraulic oilways in

the gearbox and shafts are free of obstructions.

- If the MF 3080, 3070 tractor gearbox is fitted with Speedshift. fit

the solenoid valve (1) and tighten to a torque of 18-20 Nm.

- Fit the T-piece (2) for the A/B feed pipe.

- Examine all parts for wear and discard any v.nich are faulty.

- Before assembling lightly lubricate the cones, cups, bearing bores,

bushes, gaskets and needle roller bearings.

- Using a press, fit the bearing cone (17) on to the shaft (69).

- Fit the circlip (70). Refit the shim 4.

- Reduce the thickness of the shims [3] v. nose measurement was noted on

disassembly by approximately 0.3 mm to obtain a shaft end play of 0.10

to 0.15

maximum to obtain an exact fit.

- Fit the shims [3] and cups (2) and (16).

- Assemble 1st gear (7) and its bush (8). the lock plate (9). the 1st

gear synchromesh cup (10), the 1st and 2nd gear synchromesh (11), the

2nd gear synchromesh

cup (12). the cone (13) and the 2nd gear (14)

- Refit the 1st and 2nd gear train assembly between the two partitions.

- Insert the shaft through the rear of the housing retaining the

synchromesh/gear assembly,

- Check that the bush (8) is correctly positioned in the gear (7).

- Fit the locking tool MF 458 and the locally made retaining sleeve. Fit

the washer (6)

- Using a press, fit the bearing cone (1) on the sleeve (82).

- Fit the sleeve on the shaft. To shim using formula PI, do not fit the

A/B gear train.

- Fit the bush 81V the A/B synchromesh (78). the bush (74) and the spur

washer 73 on the shaft.

- Fit nut (68) and tighten to a torque of 80-100 Nm using tool MF 456.

Method of shimming:

- Carry out Procedures to obtain a preload of P1= minus 0.14mm to minus

0.20mm

- Remove tool MF 458 and s sleeve.

- Position a dial gauge pointer at the end of the shaft.

- From the front of the housing while pulling on the shaft, turn it

first to the right then to the left so that the cones bed properly into

the cups.

- Zero the dial gauge.

- Repeat operation 100 by pushing on the shaft.

- On the basis of the dial gauge reading; select the shim thickness

required to obtain P1.

- Fit tool MF 458 and the locally made-up sleeve.

- Remove the sleeve (82) and its cone (1). 107.Withdraw the cup (2).

- Position the adjusting shims [3] which were selected in operation 103.

- Position the shim 4 on the circlip (5) side.

- Fit the cup. Fit the sleeve.

- Slide the A gear (67) on to the shaft with the bush 81 (stepped side

facing the synchromesh) and the double needle roller bearing (79)

inserting the A/B fork into the

housing.

- Use the shifter rail to retain the fork.

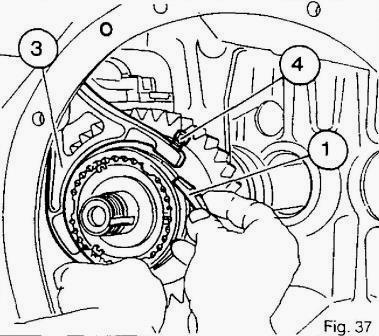

- Locate the synchromesh cup (80) and A/B synchromesh (78).

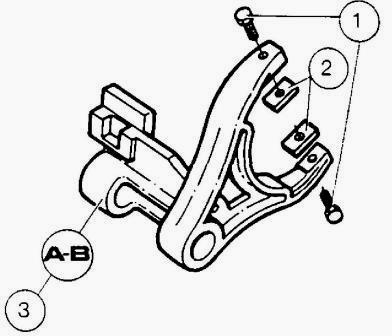

- Position the pads (1) and (2) for the fork (3). coat the screws (4)

and (5) with Loctite 241 and tighten them by hand (Fig.37).

- Check that the pads move freely in the synchromesh sliding coupling.

- Slide the B gear (76) on to the shaft with the cup (77). the bush (74)

and the needle roller bearing (75).

- Rotate gear A (67) and B (76) from right to left to ensure that the

synchromesh cups are correctly positioned (80) (77).

- Fit the spur washer /73V. The oil grooves should face the B gear.

- Using a solvent degrease the shaft thread.

- Lightly coat the nut (68) with Loctite 241 then tighten to a torque of

80-100 Nm.

- Lock the nut by flattening the collar with a suitable drift punch.

- Insert the spring (72) and the oil feed pipe (71) into the shaft.

- Remove tool MF 458 and the retaining sleeve.

- Fit the gear (18) and the synchromesh lock plate (20) the brake (21)

and 3rd and 4 gear synchromesh (23). Fit the circlip(26).

- Manually check: gear end play / shaft and gear train rotation

- Check that 1st and 2nd gear and A/B gear synchromesh function

correctly.

Fig.37

Mainshaft Reassembly MF 3080, 3070 tractor 4x2 gearbox:

Fig.38

- Assemble the following in the order shown in the housing: 1st speed

gear (7) and its bush (8). the cone (9). 1st gear synchromesh cup (10),

Island 2nd gear synchro

(11), 2nd gear synchro cup (12). cone (13) and 2nd gear (14).

- Carry out procedures 90 to 92.

- Press the bearing cone (1) on to the gear (67).

- Fit the gear(67) on to the shaft (69).

- Fit the nut (68) using special tool 3376805 Ml. Tighten to a torque of

80-100 Nm.

- Fit tool MF 458 and the retaining sleeve.

- Remove the lock from the nut.

- Remove the gear

- Refit the gear. Check that 1st and 2nd gear synchromesh functions

correctly.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader