________________________________________________________________________________

Massey Ferguson 3060, 3065 tractor Gearbox

Massey Ferguson 3065, 3060, 3070, 3080

tractors have a transmission which consists of five main housings:

- the gearbox assembly, which also serves as a clutch housing.

- the centre housing which includes the differential assembly, the power

take off line and 4 wheel-drive clutch. It also holds the side hydraulic

covers.

- the axle housings right and left.

- the lift cover.

These five parts are common to the whole range. The models fitted with 6

cylinder engines have an adapter plate located between the engine and

gearbox.

MF 3060, 3065 tractor Clutch

The clutch is a single-plate unit. The mechanism has a diaphragm which

is hydraulically operated by a piston. Clutch types: push clutch and

pull clutch. A shaft driven by a splined hub connected to the engine

flywheel passes through the gearbox assembly and transmits rotation to

the power take-off clutch.

The power take-off clutch housing drives the hydraulic pump via drive

gear.

In reverse, speed is:

- 7% faster than in forward in range A

- 7% slower than in forward in range B

Massey Ferguson 3060, 3065 tractor Gearbox

Speedshift

In addition to the main box and the reversing assembly, by means of a

hydraulic device with an epicyclic train placed before the reversing

gear, operated by a solenoid, two input speeds can be added, taking the

number of possible speeds to 32.

Creeper gear housing

By means of a housing fitted on the output shaft, after the main box, a

range of greatly reduced travel speeds can be obtained .This housing

consists of an epicyclic type reduction gear, with a ratio of 4.1,

driven mechanically, which should be engaged only if the main box is in

the slow (Tortoise) position.

MF 3065, 3060 tractor Gearbox assembly

Main box

The main gearbox has eight basic speeds (2x4). It consists of a train of

four gears to which a set of two gears is added so that a slow

(Tortoise) range and a fast (Hare) range can be obtained.

All the gears are in constant mesh and the speeds are selected by

synchromesh units, except the Hare/ Tortoise range. These eight speeds

can be selected with a single lever.

Reverse gear assembly and A/B range

This consists of an assembly of two sets of gears placed in front of the

main box; one driving, fitted on a hollow shaft, the other driven,

fitted on the main box countershaft. The two ranges are selected by two

synchro-mesh units operated by the reversing gear lever when it is moved

to the neutral position.

With this layout, the number of speeds can be doubted and 16 forward and

reverse speeds can be obtained. With a compound gear cluster located

between the hollow shaft and the countershaft, the direction of rotation

of the countershaft can be reversed.

Main gearbox

In order, the gearbox housing has the

following major components:

- the engine clutch operating device.

- the input housing enclosing the speedshift (if fitted) and the reverse

gears.

- the main gearbox.

- the creeper gear housing (if fitted).

We will restrict ourselves to describing only the main box, as each

major component is covered by an individual description in the section

dealing with it.

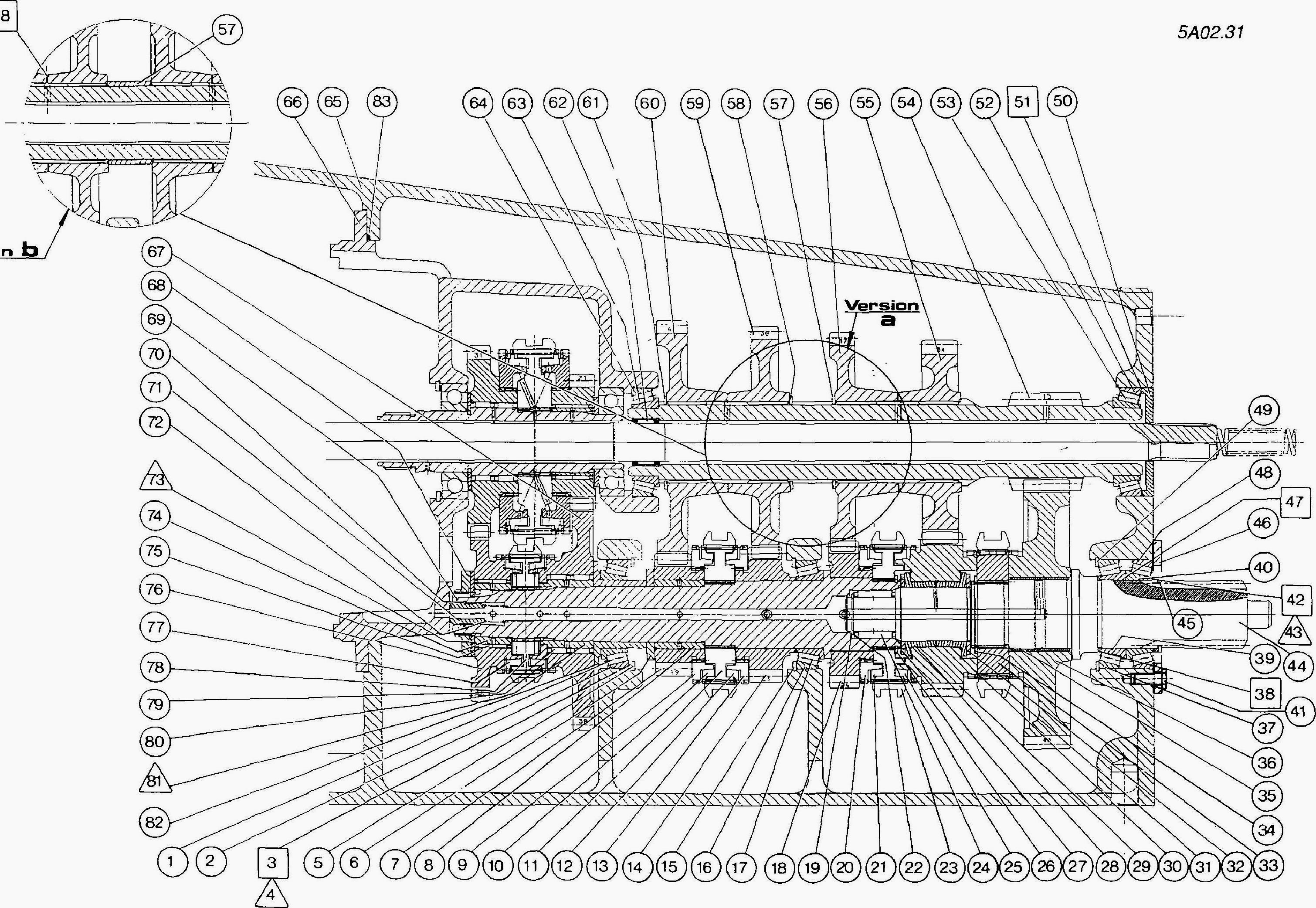

Massey Ferguson 3060, 3065 tractor

gearbox Construction

Fig.1. Part list

(1) Bearing cone, (2) Bearing cup, [3] Shims, (4) Spacer, (5) Circlip,

(6) Washer, (7) 1st drive gear, (8) Bush, (9) 1st gear synchro cone,

(10) 1st gear synchro cup,

(11) 1st and 2nd gear synchro, (12) 2nd gear synchro cup, (13) 2nd gear

synchro cone, (14) 2nd drive gear, (15) Circlip, (16) Bearing cup, (17)

Searing cone, (18) 3rd

drive gear, (19) Circlip, (20) 3rd gear synchro cone, (21) 3rd gear

synchro cup, (22) Washer, (23) 3rd and 4th gear synchro, (24) Needle

roller bearing, (25) 4th gear

synchro cup, (26) Circlip, (27) Thrust washer, (28) Combined bearing,

(29) 4th gear drive pinion (High range), (30) Combined bearing, (31)

Coupler, (32) Thrust

washer, (33) Coupler hub, (34) Circlip, (35) Bush, (36) Gear (Low

range), (37) Bearing cup, [38] Shims, (39) Bearing cone, (40) Bearing

cone, (41) Bolt, [42] Shims,

(43) Spacer, (44) Output shaft, (45) Circlip, (46) Lock plate, [47]

Shims, (48) Bearing cup, (49) Circlip, (50) Washer, [51] Shims, (52)

Bearing cup, (53) Bearing

cone, (54) Layshaft, (55) 4th driven gear, (56) 3rd driven gear, (57)

Circlip/Spacer, (58) Circlip, [58] Shim, (59) 2nd driven gear, (60) 1st

driven gear, (61) Circlip,

(62) Needle roller bearing, (63) Bearing cone, (64) Bearing cup, (65)

Gearbox housing, (66) Input shaft housing assembly, (67) A range gear,

(68) Nut, (69)

Mainshaft, (70) Circlip, (71) Oil feed pipe, (72) Spring, (73) Spur

washer, (74) Bush, (75) Needle roller bearing, (76) B range gear, (77) B

range synchro cup, (78)

A/B synchro, (79) Needle roller bearing, (80) A range synchro cup, (81)

Bush, (82) Sleeve

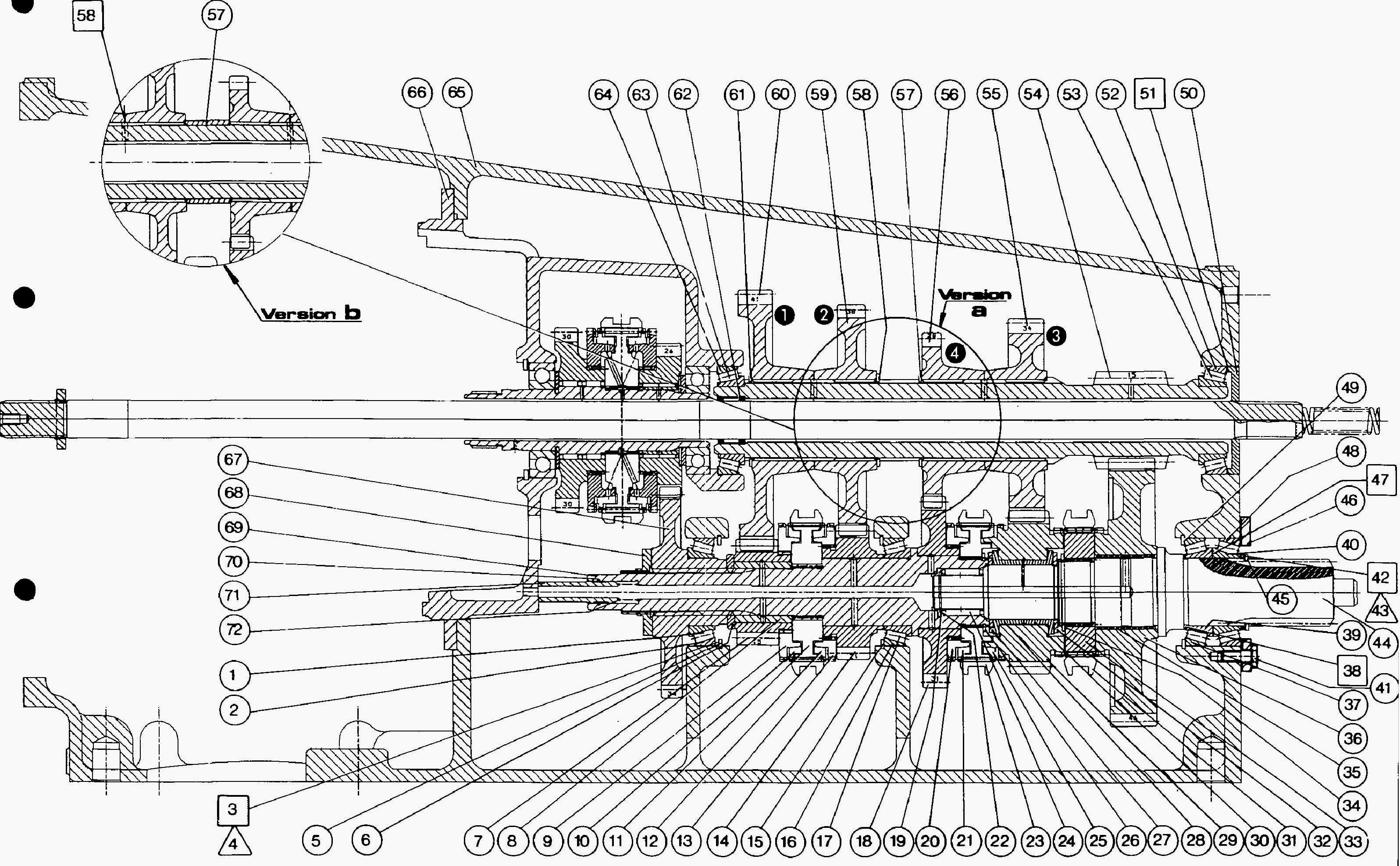

Fig.2. Part list

(1) Bearing cone, (2) Bearing cup, [3] Shims, (4) Spacer, (5) Circlip,

(6) Washer, (7) 1st drive gear, (8) Bush, (9) 1st gear synchro cone,

(10) 1st gear synchro cup

(11) 1st and 2nd gear synchro, (12) 2nd gear synchro cup, (13) 2nd gear

synchro cone, (14) 2nd drive gear, (15) Circlip, (16) Bearing cup, (17)

Bearing cone, (18) 4th

drive gear, (19) Circlip, (20) 4th gear synchro cone, (21) 4th gear

synchro cup, (22) Washer, (23) 3rd and 4th gear synchro, (24) Needle

roller bearing, (25) 3rd gear

synchro cup, (26) Circlip, (27) Thrusi washer, (28) Combined bearing,

(29) 3rd gear drive pinion (High range), (30) Combined bearing, (31)

Coupler, (32) Thrust

washer, (33) Coupler hub, (34) Circlip, (35) Bush, (36) Gear (Low

range), (37) Bearing cup, [38] Shims, (39) Bearing cone, (40) Bearing

cone, (41) Bolt, [42] Shims,

(43) Spacer, (44) Output shaft, (45) Circlip, (46) Lock plate, [47]

Shims, (48) Bearing cup, (49) Circlip, (50) Washer, [51] Shims, (52)

Bearing cup, (53) Bearing cone,

(54) Layshaft, (55) 3rd driven gear, (56) 4th driven gear, (57)

Circlip/Spacer, (58) Circlip, [58] Shim, (59) 2nd driven gear, (60) 1st

driven gear, (61) Circlip, (62) Needle

roller bearing, (63) Bearing cone, (64) Bearing cup, (65) Gearbox

housing, (66) Input shaft housing assembly, (67) Input gear, (68) Nut,

(69) Mainshaft, (70) Circlip,

(71) Oil feed pipe, (72) Spring

The main gearbox has four synchromesh speeds. With a gear fitted free

running on the output shaft, to which it can be locked by a coupler, the

initial four speeds can

be doubled to obtain the basic eight speeds.

The mainshaft and layshaft

are supported by taper roller bearings. The output shaft is fitted in

two taper roller bearings and

one needle roller bearing.

All the gears are helical and in constant mesh. The lubricating oil

comes from the front housing and passes through an oilway drilled along

the centre line of the

mainshaft and output shaft.

Radial oilways direct oil to the various

different lubrication points of the gears, bearings and bushes.

The top shafts are lubricated by the film of oil circulating between the

PTO shaft and the layshaft. This film lubricates the end taper roller

bearings and the needle roller

bearing (62).

Radial oilways in the shaft (54) and radial recesses on the driven gear

make oil pass between all the gears. The contact area between teeth of

the shaft (54) and the

gear (36) is also lubricated by a radial hole drilled in the shaft.

To ensure correct operation according to the forces to which the

transmission is subjected, the bearings are fitted with preload (in the

case of the mainshaft) or with

end float (in the case of the layshaft).

The output shaft can be shimmed

with either a small amount of play or light preload.

Speed driving gear (7) is fitted free-running on a bush (8), the 2nd

speed driving gear (14) and 3rd speed driving gear or 4th speed driving

gear (4x2) (18) are fitted free

running on the shaft direct.

The 4th speed driving gear or 3rd speed driving gear (4x2) (29) is

fitted on needle roller bearings (28) and (30). These act as axial

thrust bearings.

The hub (33) of coupler (31) is solid with the output shaft (44). Driven

gears (55), (56), (59) and (60) drive the layshaft (54) by splines. The

teeth of shaft (54) is in

constant mesh with the Tortoise gear (36), fitted free-running on the

output shaft.

MF 3060, 3065 tractor gearbox Operation

Low (Tortoise) range

This speed is engaged by moving one of the couplers of the synchromesh

devices (11) and (23) to link in rotation the countershaft (69) with one

of the 4 gears fitted

free-running.

Which ever gear is selected, the movement is transmitted to the layshaft

(54). The output shaft (44) is driven by the layshaft machined teeth in

constant mesh with the

free-running gear (36) solid with the output shaft by moving the coupler

(31) of hub (33) back.

High (Hare) range

This range is selected by moving forward the coupler (31) which puts the

driving gear (29) and the output shaft in direct mesh,

Therefore, in 4th speed (4x4) and in 3rd speed (4x2), the layshaft (54)

is non-functional.

The other speeds are obtained by movement of the

couplers of the

synchromesh devices (11) and (23) as in the Tortoise range. Movement is

transmitted to the output shaft (44) by driven gears (55) and (29).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader