________________________________________________________________________________

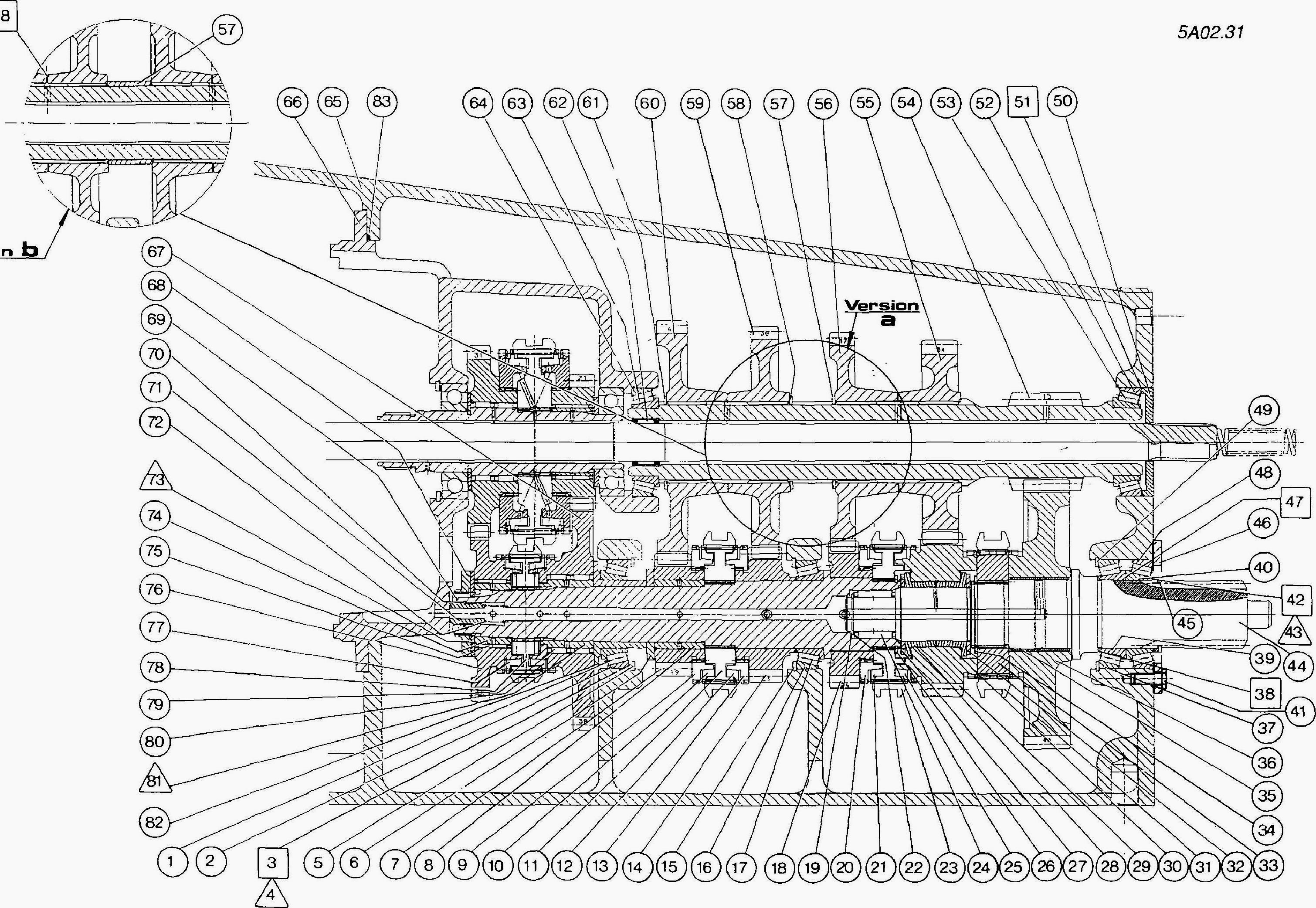

Massey Ferguson 3050, 3085 tractor Gearbox Output shaft and Layshaft

Massey Ferguson 3085, 3050, 3125, 3105

tractors gearbox Output shaft - Reassembly:

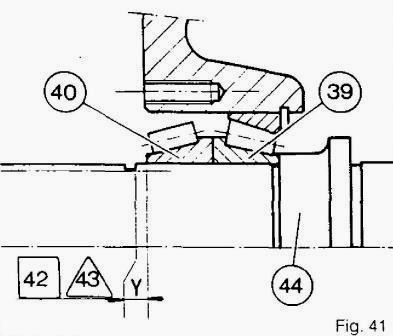

Fig.41

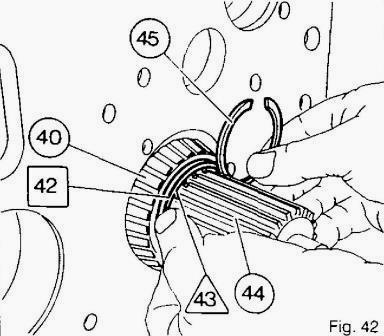

Fig.42

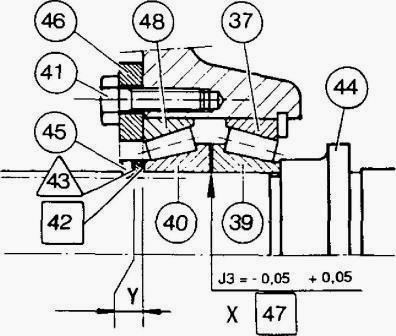

Fig.43

- Fit the circlip (49) and the bearing cup (37).

- Refit the needle roller bearing (24), washer (22) and circlip (19) on

to the shaft (44). Insert the shaft into the housing without the gears.

- Slide the bearing cones (39) and (40) on to the shaft.

- The aim of this procedure is to prepare J3 shimming (Fig.41). Hold the

cones (39) and (40) against the step in the shaft (44) using hand

pressure.

- Take up the clearance Y between the rear of cone (40) and the groove

for the circlip (45) with shim adjuster [42] and spacer /43V Select a

new circlip of a size that fits snugly into the groove (Fig.42).

- Shim to obtain (Fig.43): J3 = minus 0.05 to plus 0.05 The aim of this

procedure is to take up the play between the cones (39) and (40) and the

cups (37) and (48) while keeping the above-mentioned shimming tolerance.

- Fit the circlip (45). Position the spacer on the circlip side.

- Fit the cup (48) and the lock plate (46). Tighten the bolts (41) to a

torque of 27-32 Nm.

- Position the dial gauge pointer a; the end of the shaft (44).

- For MF 3050, 3085 tractor gearboxes fitted with the creeper range, use

the gearbox plate instead of the lock plate. Tighten the bolts to a

torque of 34-52 Nm.

- Push on the shaft and turn it to right and left so that the cones bed

correctly into the cups.

- Zero the dial gauge. Carry out procedure 148 but pull on the shaft.

- If end play exceeds 0.05 mm select the number of shims X [47] to

obtain: J3 = minus 0.05 to plus 0.05 Important: The shim(s) X [47]

selected for J3 should be fitted between the cones for the following

shimming procedures.

- Remove the circlip (45). Remove the shim /43\ and the shim adjusters

[42].

- Measure the thickness Y of all the shims [42] and /43\ (this

measurement will be useful for J5 shimming).

- Remove the bolts (41) and the lock plate (46).

- Remove the cup (48). the cones (40) and (39) and the shaft (44).

- Assemble in the housing : the Low range gear (36), the coupler (31).

the hub (33). the thrust washer (32). the 4/4 gearbox 4th gear/4 x 2

gearbox 3rd gear (29) with its combined needle roller bearings (30) and

(28), the thrust washer (27) and the synchromesh cup (25).

- If the bush (35) is worn, replace the gear assembly (because the bush

is bored out after it has been fitted).

- If the combined bearings (30) and (28) are worn, replace the gear

assembly (it is factory fitted).

- Engage the input shaft (44) retaining the gear train assembly,

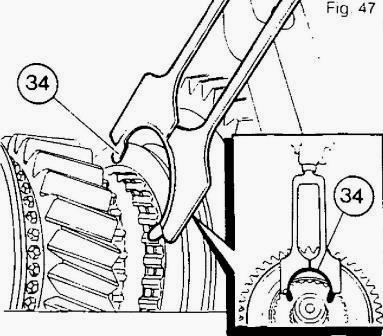

- Gently pull the shaft rearwards to expose the circlip (34) groove.

- Fit the circlip (34) using tool MF 459 (Fig.47), Note: Check that the

circlip is correctly fitted.

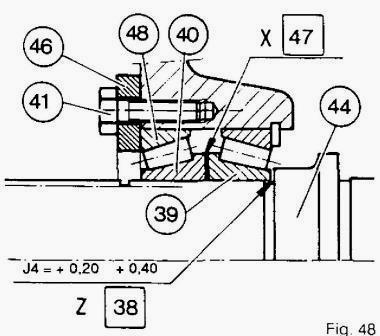

- Slide the following on to the shaft: the cone (39). the shim(s) X [47]

selected in operation 151. the cone (40) and the cup (48).

- Fit the lock plate (46). Tighten the bolts (41) to a torque of 27-32

Nm.

- Fit shims to obtain (Fig.48) : J4 = plus 0.20 to plus 0.40 This

shimming procedure produces end play on the gear (29) (4th Low 4x4

gearbox) (3rd Low 4 x 2 gearbox).

- Carry out procedures 147 to 150. On the basis of the reading obtained

on the dial gauge select the thickness of shims Z [38] to obtain J4.

- Remove the bolts (41) and the lock plate (46). Remove the cup (48).

- Withdraw the cones (40) and (39) and the shims) X[47]

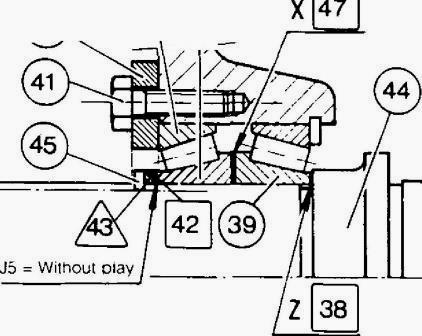

- Slide the following on to the shaft: the shims Z [38], the cone (39).

the shim(s) X [47] and the cone (40),

- (Fig.49) Shim to obtain: J5 = Zero play

- The aim of this shimming procedure is to lock the cones (40) and (39)

on to the shaft (44).

- From the thickness of shims Y [42] /43V selected in operation 154,

deduct the thickness of shims Z [38] and X [47] to obtain: J5 = Y -

(Z+X).

- Slide the number of shims selected in operation 171 on to the shaft.

- Fit the circlip (45). The circlip must be a snug fit in its groove.

Check that it is correctly positioned.

- Check the shaft and gear train rotation manually.

- Check that the 3rd and 4th speed synchromesh and the High/Low range

coupler operate normally.

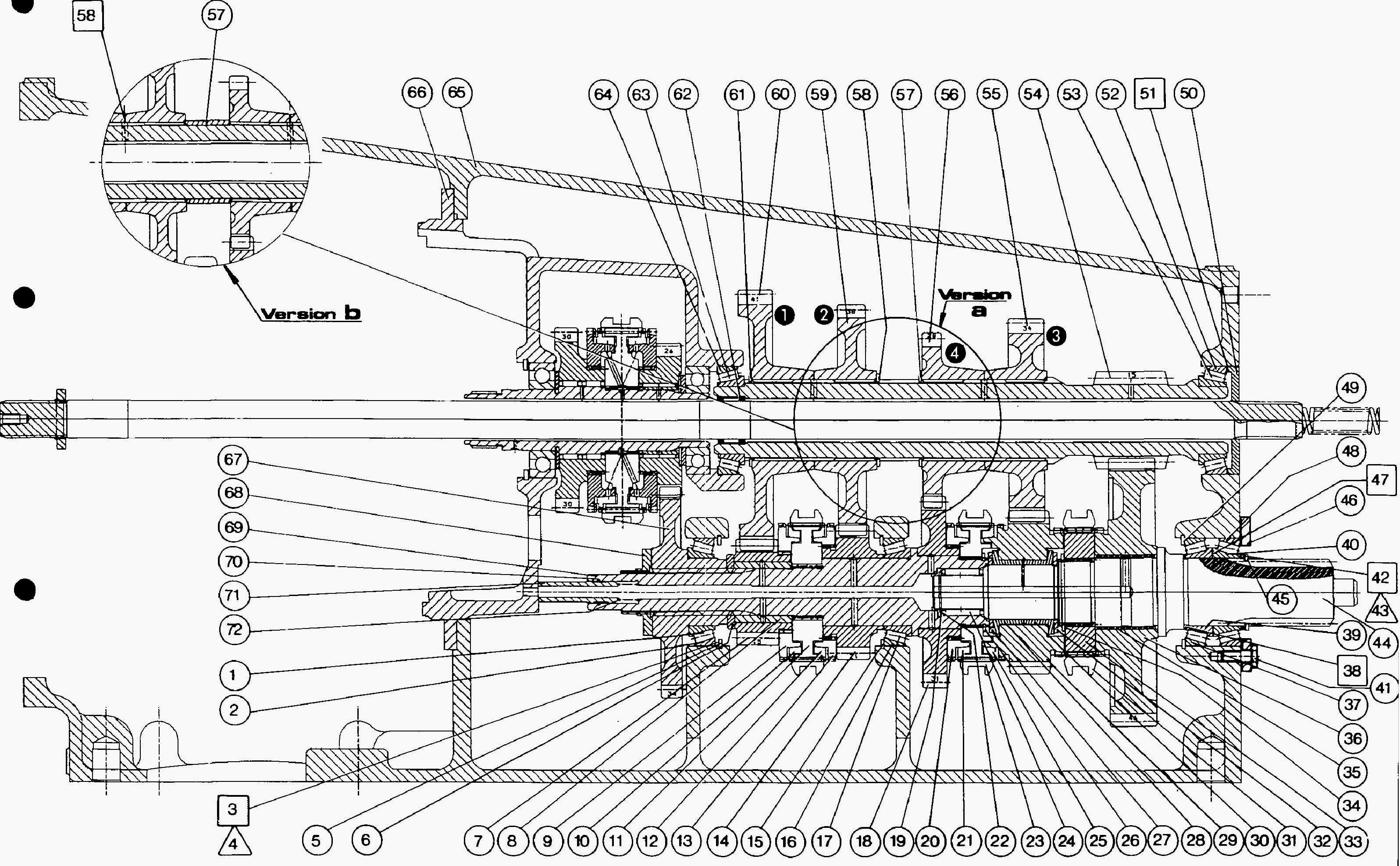

Fig.1

Fig.2

Fig.47

Fig.48

Fig.49

Massey Ferguson 3050, 3085 tractors Creeper Gearbox

Refitment:

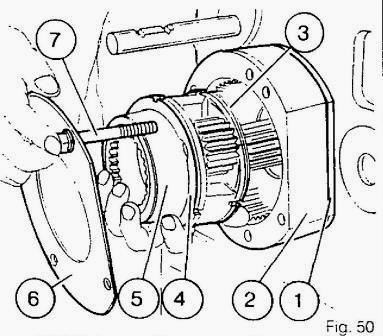

Fig.50

- Position the lock plate (1) and the ring gear (2) on the housing.

- Attach the friction washers (3) and (4) to the planetary carrier (5)

using Amber Technical-grease.

- Slide the pinion carrier on to the output shaft.

- Position the cover plate (6).

- Fit the bolts (7) and tighten to a torque of 34-52 Nm.

Massey Ferguson 3050, 3085 tractor gearbox Layshaft - Reassembly:

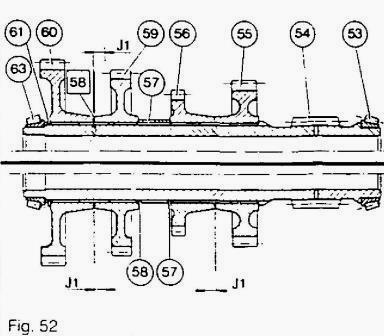

Fig.52

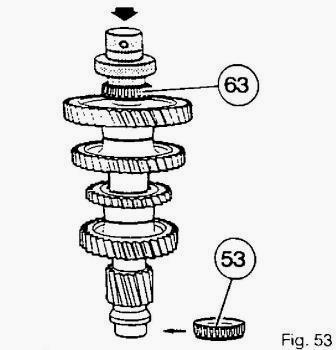

Fig.53

- A new designed shaft was introduced from serial no. P345012. Tractors

prior to this are built using version a.

- Fit the needle roller bearing (62) against the shoulder on the shaft

(54) using a press. Check that the needle roller bearings turn freely in

the cage.

- Ensure that the circlips fit easily into their grooves.

- The gap J1 is calculated according to machining tolerances (Fig.52).

Carry out procedures 28 and 29 in reverse.

- Slide the spacer (57) on to the shaft. Fit the 2nd gear (59). the 1st

gear (60) and the circlip (61).

- Using a set of shims, measure the space between the 1st gear (60) and

the 2nd gear (59). On the basis of the measurement, select a thickness

of shims to obtain

(Fig.52): J1 = 0 to plus 0.25.

- Remove the circlip (61) and the gear (60). Slide the shims already

selected on to the shaft. Fit the gear and the circlip.

- Using a press, fit the bearing cones (63) and (53) holding the

assembly in a suitable jig (Fig.53).

- Carry out procedures 23 and 20 in reverse.

Input shaft housing - Refitment:

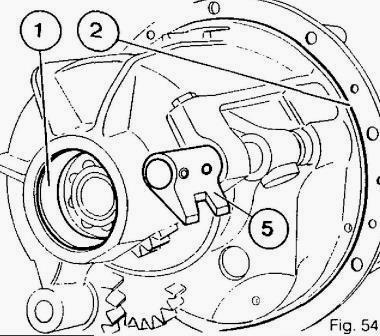

Fig.54

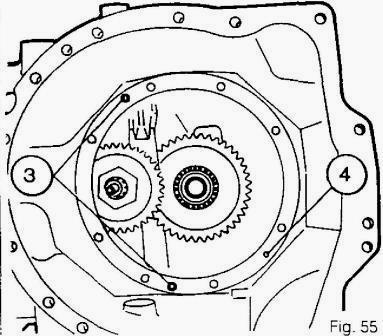

Fig.55

- Clean the mating face.

- Check that the cup (1) and the «o» ring (2) are fitted (Fig.54).

- (Fig.55) Fit the O-rings (3) and the locating dowel (4) in the

housing.

- Offer up the input shaft housing assembly (66) into the housing by

tilting st to the left then tilting it to the right to engage the

reverser gear train into the A/B gear train.

- At the same time, check through the selector cover that the reverse

shuttle selector (5) (Fig. 54) is not in contact with the housing

partition and that the layshaft cone

(63) engages in the cup (64).

- Position the housing assembly over the locating dowel.

- Fit the bolts and tighten to a torque of 45-60 Nm. Remove the

retaining tool. Shim to obtain: J2 = plus 0.04 to plus 0.12

- Fit the locally made-up tool into the MF 3050, 3085 tractor gearbox

layshaft.

- Lightly comroress the spring by tightening the nut on the tool so that

the cones seat correctly in the cups.

- Rotate the shaft several times.

- Measure the space X using a depth gauge between face A of the cup (52)

and face B of the housing.

- Measure the thickness Y of the washer (50).

- Calculate the difference between X and Y.

- Determine the thickness of shims required to obtain a play of plus

0.04 to plus 0.12.

- Remove the compression tool.

- Position the shims [51] selected in procedure 202.

- Press the washer into the housing.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader