________________________________________________________________________________

MF 3050, 3070 Tractor Gearbox Shifter rail, forks and Selector

Massey Ferguson 3070, 3050, 3125, 3105

tractors gearbox Shifter rail and forks Reassembly

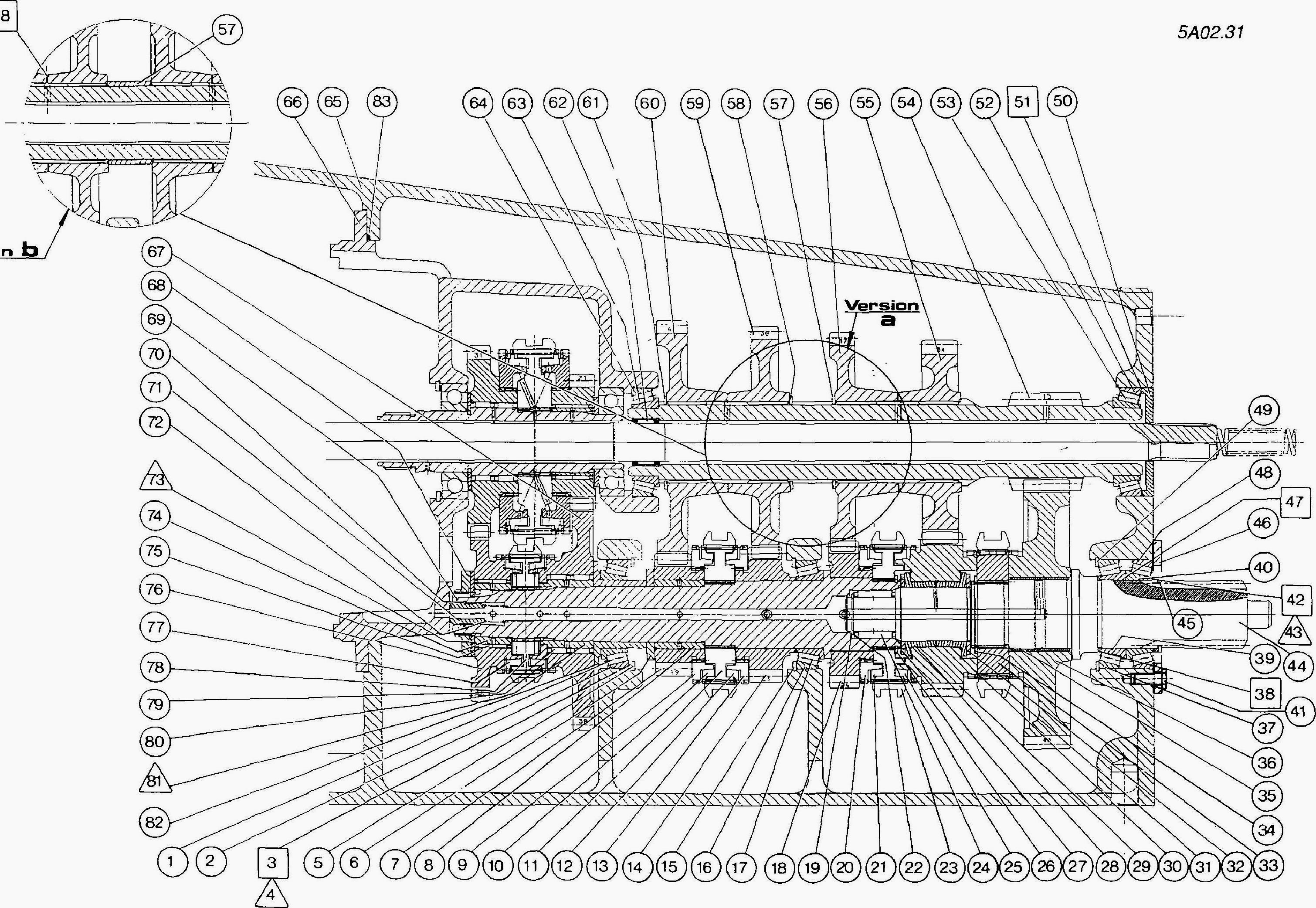

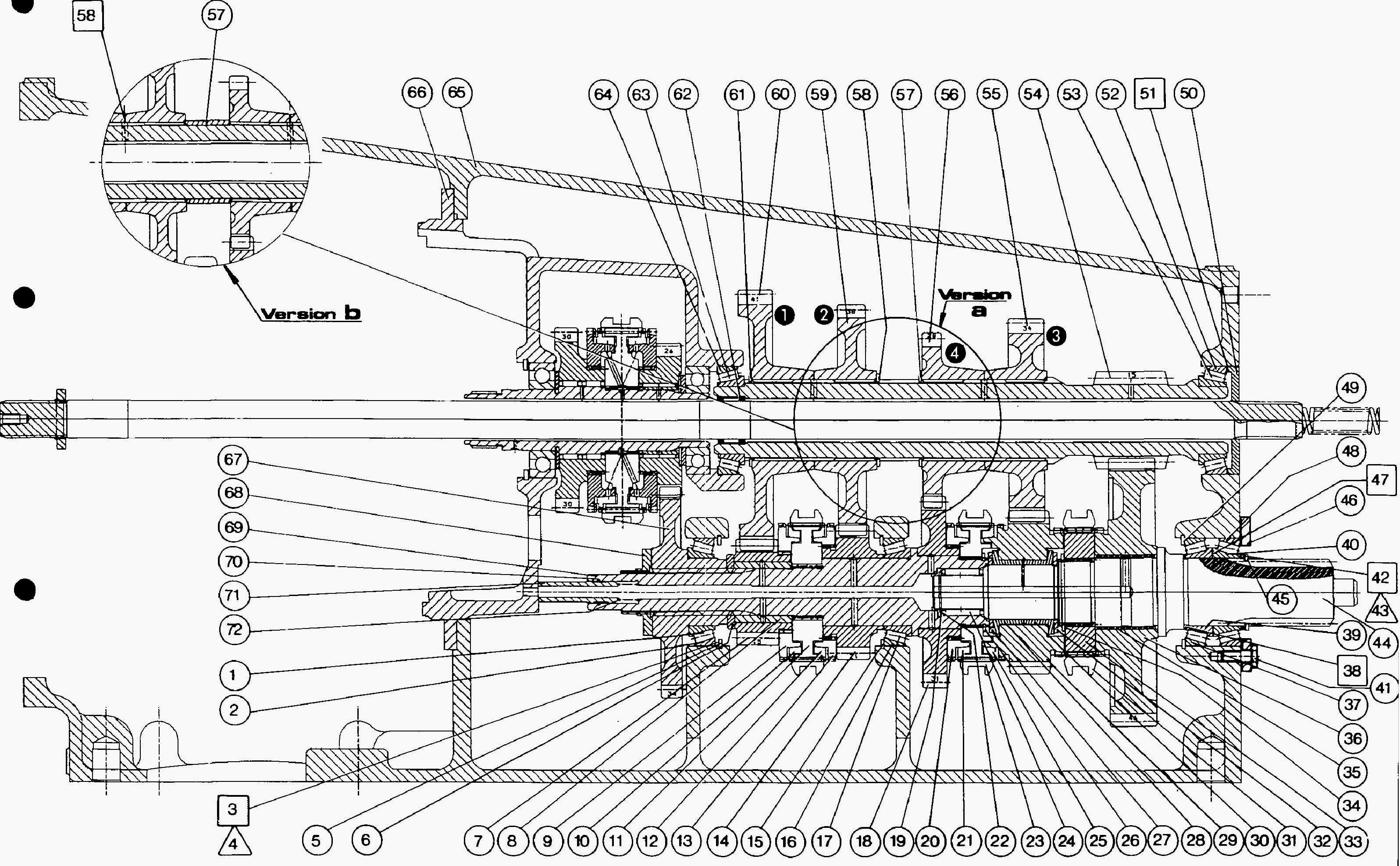

Fig.1

Fig.2

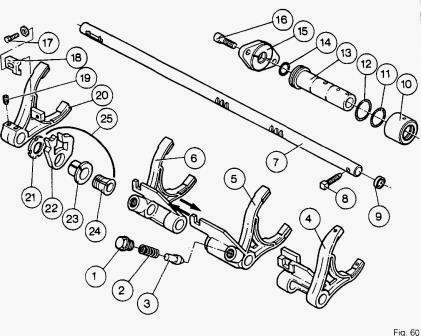

- Check that the hydraulic ports of the High/Low cylinder (10) are

unobstructed.

- Fit the cylinder (10) together with the «0» ring (11) in the housing.

- Position the High/Low fork (20) in the coupler.

- Fit the seals (12) and (14) on the piston (13) then insert it into the

cylinder bore.

- The setscrew holes should face the tapped holes in the fork.

Immobilize the fork with a setscrew (19).

- Clean and assemble the mechanical lock (22), the tapered bearing (23),

the cone (24) and castellated nut (21).

- Fit the 3rd and 4th speed gear forks (6), 1st and 2nd gears (5) and

the lock assembly (25).

- Insert the selector rail (7) through the rear of the housing and slide

it into the piston, the Jock assembly and the forks.

- For the MF 3070, 3050 Tractor 4x4 gearbox, do not forget the Al B fork

(4).

- Fit the bearing (15) and tighten the bolts (16) to a torque of 27-32

Nm.

- Clean the setscrew (8) with solvent, coat with Loctite 542 and tighten

to a torque of 28-43 Nm.

- Clean the insert (9). coat with Loctite 542 and press it in level with

the housing.

- Fit the locking plungers (3), the springs (2) and tighten the plugs

(1) to a torque of 50-70 Nm. Note: Gearbox fitted with creeper gears

(Fig.61).

Fig.60

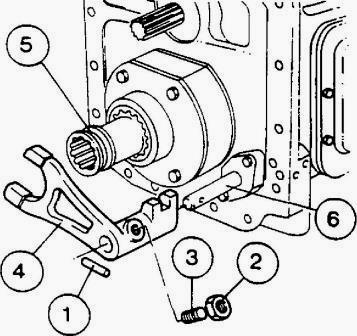

Fig.61

- Fit the sleeve (5), the fork (4) and the pin (1). Position the fork

and the locking plunger (3) on the flat of the shifter rail (6) (between

the two locking notches).

- Tighten the locking peg to compress the ball. Slacken the screw a

quarter turn. Clean the nut (2) with solvent and coat with Loctite 241.

- Tighten to a torque of 15-20 Nm. Check that the fork is correctly

locked. Setting the High/Low range fork.

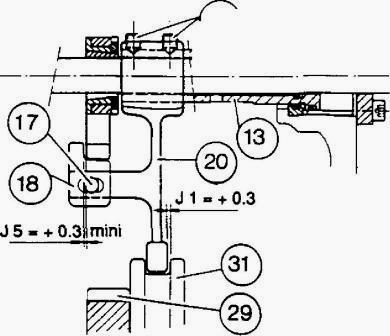

- Principle: Positioning or the selector fork (20) on the rail is made

possible by the different centre to centre distances of the tapped holes

Y and of the notches Z on the

piston (13).

- The fork's position is altered by turning either the front screw or

the rear screw as necessary (Fig.62).

- Position the control piston (13) and the coupler (31) in the High

range.

- Keep the coupler in contact with the high range gear (29) (3rd gear on

the 4 x 2 gearbox - 4th gear on the 4 >; 4 box).

- Adjust the position of the fork (20) by turning the two adjusting

screws (19) after cleaning them with a solvent and lightly coating them

with Loctite 221 to obtain a play

of J1 s 0.3 mm between the rear face of the plate and the coupler.

- Use the locally made-up tool to carry out the adjustment.

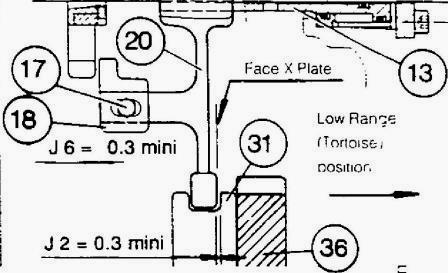

- Position the control piston (13) and the coupler (31) in Low range.

- Check that there is a play of J2 = 0.3 minimum (value obtained by J1

adjustment) between the plate and the coupler with the latter in contact

with the Low range gear

(36) (Fig.65).

- Tighten the screws to a torque of 35 Nm without changing the

adjustment. Note: In Low range position, if the face X of the fork (20)

plate is in contact with the coupler

(Fig.65) increase the play J1.

- Move the fork into the Low range position.

- Slightly slacken the castellated nut (21). Lightly coat the thread of

the cone (24) with Loctite 270.

- Move the forks into the neutral position.

- Divide the J3 and J4 play (minimum 0.3 mm) equally so that the

mechanical lock (22) moves freely.

- Tighten the castellated nut (21) to a torque of 50 Nm using spanner

3615334 M01 and a spring balance.

- Coat the inner face of the slider (18) with Loctite 648 and the bolt

(17) with Loctite 241, Fit the washer and the bolt.

- Equalize the J5 and J6 clearances (minimum 0.3 mm) between the slider

and the lock in the High and Low range positions.

- Tighten the bolt to a torque oi 27-32 Nm.

- Check the operation of the High/Low range and of the lock.

- Check the operation of the gears and of the A/B range.

Fig.62

Fig.65

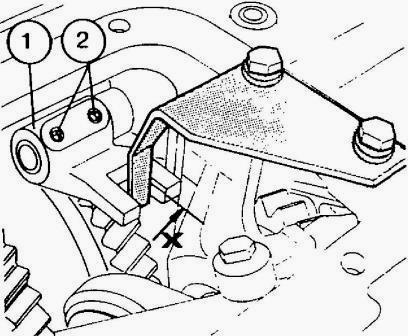

MF 3050, 3070 Gearbox Reverse shuttle selector - Adjustment:

Fig.71

- Move the selector (1) into neutral.

- Fit and tighten service tool 3582434 M01 with two centring bolts

fitted with spacers.

- Coat the setscrews (2) with Loctite 221.

- Position face X of the reverse shuttle selector in contact with the

service tool using the screws (2).

- Tighten the screws to a torque of 35 Nm.

- Remove the tool.

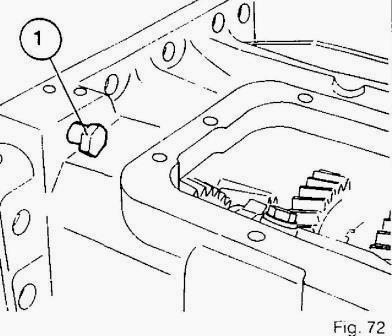

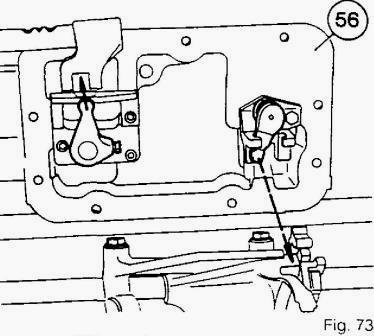

Selector cover – Refitment MF 3050, 3070 Tractor 4x2 Gearbox:

Fig.72

- Clean the mating face of the cover (56).

- Move the reverse shuttle selector into neutral. Engage 1st gear.

- Coat the mating face of the gearbox housing with a gasket sealant.

Note: Remember to position the bolt (1) on the housing (Fig. 72).

- Turn the two cover levers to the left, keeping them parallel.

- Lay the cover on the gearbox ensuring that the levers are correctly

positioned in the selectors (Fig.73).

- Carry out procedure 5 in reverse, Note: Tightening torque 50-70 Nm.

Check:

- the movement of all the gears and the position of the High/Low

(Hare/Tortoise) range,

- the operation of the reverse shuttle.

Fig.73

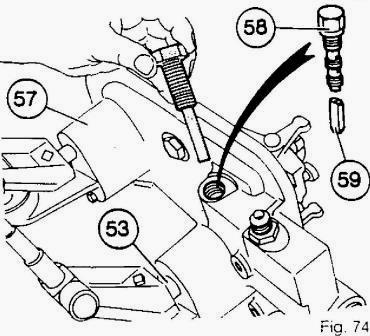

MF 3050, 3070 Tractor 4x4 Gearbox

Fig.74

- Clean the mating face of the cover (57).

On the gearbox:

- Check that the reverse shuttle selector is in neutral and the A/B fork

in position B (forwards).

- Engage 1st gear.

On the cover:

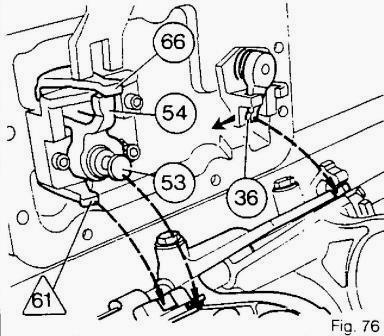

Fig.76

- Remove the pressure valve (58) and the plunger 59 (Fig. 74).

- Lock the control shaft (53) in position B with lugs (66) and (54)

lined up (Fig. 76) using tool 3615053 M01 (Fig.74) (tighten but not

fully).

- Move the lug 61 of the A/B fork into position B (forwards). Move the

gear lever to the left (into 1st) (36).

- Assemble the cover on the gearbox by engaging the lugs (54) and (66)

in the reverse shuttle selector and the lug 61 into the A/B fork, then

engage the lug (36) into

the 1st and 2nd gear fork and the mechanical lock (Fig.76).

- Position the cover. Fit the bolts and tighten to a torque of 50-70 Nm.

Remove tool 3615053 M01.

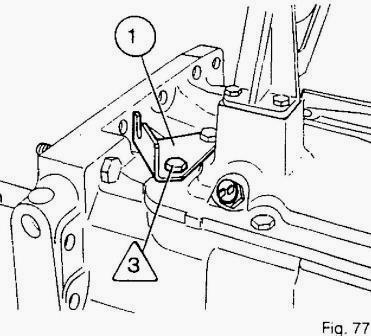

- For a gearbox fitted with creeper gears, fit the cable bracket (1)

(Fig. 77) To correctly centre the cover, first tighten bolt 3 (Fig.77).

Carry out a manual check, using

the levers, that the lugs have been correctly fitted into the selectors.

- Install the plunger 59 and the pressure valve (58) and tighten to a

torque of 18-20 Nm.

Check:

- the free movement of all gears

- the High/Low range positions

Adjust the A/B range.

Fig.77

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader