________________________________________________________________________________

Removing and install the MF 6465, 6470, 6499, 6495 tractor right-hand hydraulic cover plate

Immobilise the tractor. Chock the left rear wheel.

If the Massey Ferguson 6465, 6470, 6499, 6495 tractor is not equipped

with a Park Lock device, engage the hand brake.

Chock between the frame and the front axle (optional).

Partially drain the intermediate housing (GPA30 rear axle) or the centre

housing (GPA20 and GPA40 rear axles).

Remove the rear right-hand wheel. Place a safety stand under the trumpet

housing. Mark and disconnect the pipes or hoses, the solenoid valve

harnesses (depending on version), switches and the engine speed sensor

connected to the hydraulic cover plate (8).

Remove the 60 μ filter (49) (GPA30, GPA40 rear axles).

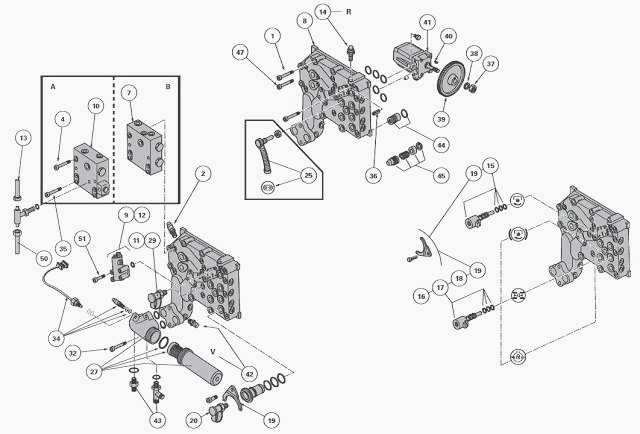

Unscrew:

- the screws (32). Remove the main filter assembly (27);

- the screws (4). Remove the single priority block (B) or the hydraulic

unit with two priority blocks (A+B).

In order to avoid draining the trailer brake system on MF 6465, 6470,

6499, 6495 tractors fitted with a two-priority block hydraulic unit, it

is recommended to remove the complete unit from the hydraulic cover

plate without disconnecting the control hose (22) from the brake master

cylinders (40 kph tractors) or from the block/valve

assembly (tractors fitted with high-pressure braking).

Unscrew the screws (1). Release and remove the hydraulic cover plate.

Remove the seal (4). Discard this seal.

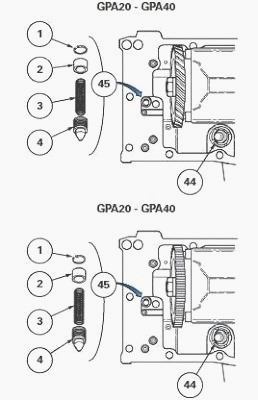

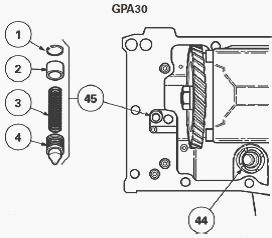

If necessary, remove the safety valve (45)

from the low pressure system by proceeding as follows:

- Compress the spring (3) using a screwdriver.

- Remove the circlip (1).

- Remove the components (2) to (4).

If necessary, unscrew the castellated collar (2) (GPA40) using pin

wrench 3378466M1. If necessary, discard and replace the "O" ring (1).

Reinstall

Clean the mating face of the intermediate housing (GPA30) or centre

housing (GPA20 and GPA40) and the mating face of the right-hand

hydraulic cover plate.

If necessary, screw on and tighten the castellated collar (2) using the

pin. If necessary, reinstall the safety valve (45).

Check that the component (4) slides freely in its housing after

reinstalling.

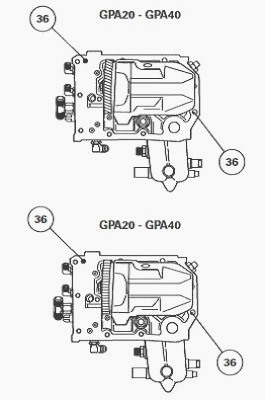

Check the Massey Ferguson 6470, 6465, 6499,

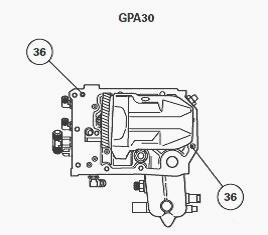

6495 hydraulic cover plate for presence of:

- the locating pins (36);

- the rivets obstructing the end of the hydraulic channels of the

hydraulic cover plate faces (external and internal).

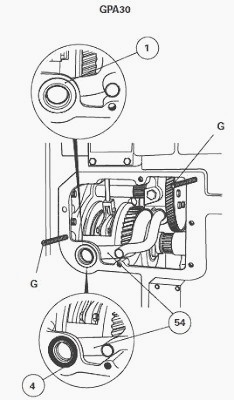

For GPA30, if necessary:

- position the pipe of the 5 bar safety valve in the intermediate

housing by placing its end, Installed with a seal, in the Mecanindus

pin. This pin is located on partition C of the intermediate housing;

- Install the charge pipe (54) fitted with an "O" ring (52) in the

intermediate housing by placing the pipe notch in the pin (1).

Lightly smear the seal (4) with miscible

grease. Position this seal:

- on the collar of the pipe (54) (GPA30);

- on the castellated collar (2) screwed onto the pipe (3) (GPA40).

Lightly smear the mating face of the intermediate housing (GPA30) or

centre housing (GPA20 and GPA40) with a sealing product such as Loctite

5206 or equivalent.

For the MF 6470, 6465, 6499, 6495 GPA20 and GPA40 rear axles, do not

obstruct the PTO hydraulic port.

If necessary, screw on two diametrically opposed guide studs (G) onto

the intermediate housing (GPA30) or centre housing (GPA20 and GPA40).

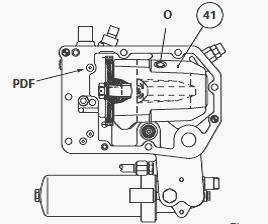

Fill the variable displacement pump (41) with clean transmission oil

through port O.

Slide the cover plate onto the guide studs (G) previously screwed onto

the intermediate housing (GPA30) or centre housing (GPA20 and GPA40).

Using a bronze hammer, gently tap the rim of the hydraulic cover plate

(8) to begin engagement of the locating pins (36) in the intermediate or

centre housing.

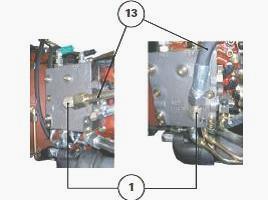

When fitting the hydraulic cover plate to the intermediate or centre

housing, check between the mating faces (cover plate and housing) to

ensure that the continuity pipe (1) (GPA20 and GPA40) or (55) (GPA30) is

correctly fitted in the 5 bar safety valve (44) as per the GPA40

example.

Screw in the screws (1) and simultaneously remove guide studs G (if

used). Tighten these screws to a torque of 120-160 Nm. If resistance is

felt during tightening, do not continue.

Move aside the hydraulic cover plate for the intermediate housing

(GPA30) or centre housing (GPA20 and GPA40) and check that the

continuity pipe or (55) is fitted in the 5 bar safety valve.

Also turn the driven gear (39) of the Massey Ferguson 6465, 6470, 6499,

6495 variable displacement pump to assist with gear engaging.

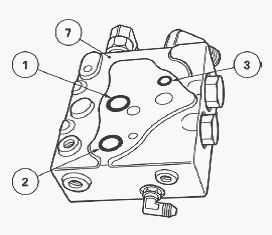

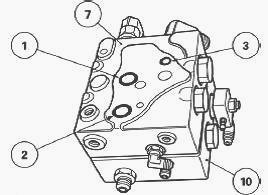

Replace the "O" rings (1) to (3) for the single priority block (7)

(tractors without trailer braking) or for the hydraulic unit with two

priority blocks [(7) and (10)] (tractors with trailer braking).

Reinstall the single priority block or the hydraulic unit with two

priority blocks (7) or [(7) and (10)]. Lightly smear the thread of the

screws with Loctite 542 or equivalent. Tighten these screws to a torque

of 25 - 35 Nm.

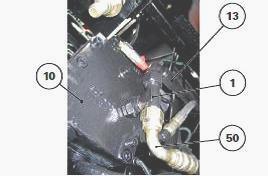

For MF 6465, 6470, 6499, 6495 tractors fitted

with a GPA30 rear axle and a trailer brake mechanism:

- Tighten the T connector (1) in the vertical position. Never replace

the T connector (1) with a standard plug.

- Tighten the hose (13).

- Temporarily tighten the hose (50) while awaiting the filling

operation.

For Massey Ferguson 6499, 6470, 6465, 6495

tractors fitted with a GPA20 or GPA40 rear axle and a trailer brake

mechanism:

- Tighten the elbow union (1). Never replace the elbow union 1) with a

standard plug.

- Tighten the pipe or hose (13) (depending on version).

If necessary, adjust the engine speed sensor

located on the hydraulic cover plate. Reconnect:

- the switches;

- the solenoid valve harnesses;

- the pipes and hoses.

Top up the rear axle oil level. Check using the dipstick or the sight

glass (depending on version).

For MF 6499, 6470, 6465, 6495 tractors

equipped with a GPA30 rear axle and a trailer brake mechanism:

- Charge the hose (50) for the priority block (10).

- Definitively tighten the hose (50).

If the variable displacement pump had to be replaced, perform the

hydraulic tests. Lift the right-hand side of the tractor rear axle.

Reinstall the wheel. Remove the axle stand. Tighten the wheel nuts.

Check for correct operation:

- of the electrical and electronic circuits;

- of the switches;

- of the solenoid valves.

Carry out a road test.

Check tightness of:

- the right-hand hydraulic cover plate;

- the mating faces;

- Hydraulic unions

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader