________________________________________________________________________________

Massey Ferguson 6290, 6270, 6490, 6280 tractor variable displacement hydraulic pump

Variable displacement hydraulic pump

description

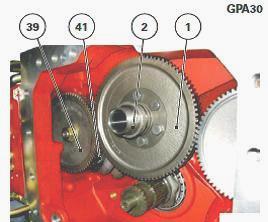

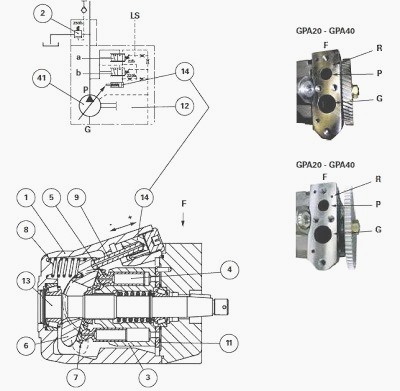

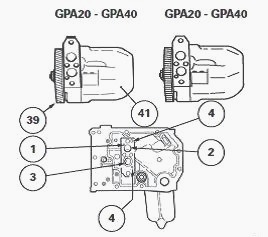

The variable displacement hydraulic pump (41)

Installed inside the Massey Ferguson 6290, 6270, 6490, 6280 right-hand

cover plate is driven by:

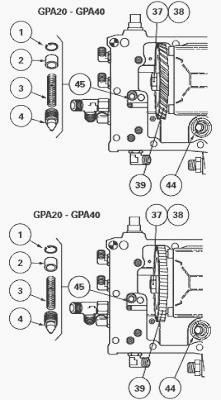

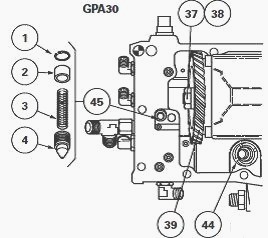

- the gears (1) and (39) (GPA30 rear axle);

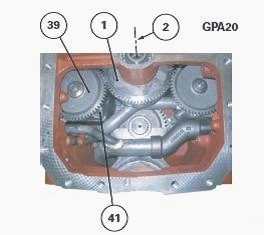

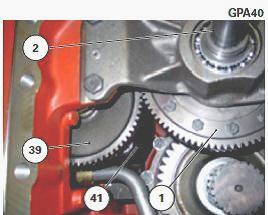

- the Massey Ferguson 6290, 6270, 6490, 6280 tractor PTO clutch housing

teeth (1) (GPA20 and GPA40 rear axles). The helical teeth of the gear

(39) (GPA20 and GPA40) and its connected gear is replaced by spur cut

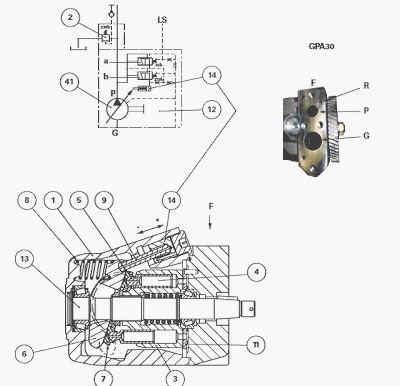

teeth. It comprises a body (1) and a cylinder (3) driven by the shaft

(13).

The cylinder contains nine axial pistons (4) thrust against ball joints

(5) in contact with plate (6) via the pads (7).

The angle of the plate is obtained by the equilibrium between the spring

(8), the pushrod (9) and the piston (14) controlled by a hydraulic

regulator receiving the Load

Sending (LS) pilot flow pressure from the high pressure (HP) components

via the single priority block or the hydraulic unit with two priority

blocks.

Depending on the angle of the plate, the length of travel of the axial

pistons (4) is modified, thus permitting the flow rate to adapt to the

operating conditions. The distribution plate (11) at the rear of the

cylinder, places the piston chambers in communication with the suction

ports and the pump delivery.

The ball joints (5) are drilled to provide lubrication between the pads

(7) and plate (6). The oil is then sent to the housing via port O.

The pressure relief valve is screwed into the upper left of the

right-hand hydraulic cover plate. The hydraulic regulator is fitted with

a diagnostics connector (Load Sending signal).

This is linked to the variable displacement pump (41) via the ports

drilled in the right-hand hydraulic cover plate. The diagnostics

connector is used to control the high pressure at the MF 6465, 6470,

6499, 6495 variable displacement hydraulic pump outlet.

Operation

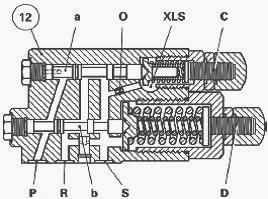

Standby position

When the engine stops, the spring (8) automatically places the pump in

its maximum flow rate position.

When the engine is started, all ports are closed, and in theory no flow

is required. The pressure increases in line P. When it reaches 22 bar,

it pushes the hydraulic regulator spool "a" and connects with port R.

The pressure acts on the piston (14) and the pushrod (9) of the pump,

which moves the plate (6) into zero flow rate position. In practice, a

weak 3 to 5 bar flow rate remains in the MF 6290, 6270, 6490, 6280

tractor steering system, increasing the standby pressure to 28 bar.

Working position

When a function is activated (e.g.: an auxiliary spool valve), the 22

bar standby pressure drops as the system is opened. The 22 bar spring

restores the hydraulic regulator spool "a" to its initial position. The

piston (14) is linked to the return via S and R.

The spring (8) returns the pump plate (6) to full flow rate. The flow

rate from the pump creates the LS (load sending) pressure required to

activate the function.

The LS function then created balances the piston between, on the one

hand, the LS pressure plus the 22 bar pressure of the spring and, on the

other hand, the pump output pressure P.

As long as the spool "a" has not been balanced and is not maintained by

the pump supply, the piston (14) remains connected to the return and the

pump plate (6) at full flow rate (pump pressure P = LS pressure + 22

bar).

The closed centre system varies the pressure and flow rate in the

hydraulic system. Pump delivery pressure = XLS use pressure + standby

pressure (22 bar).

Sufficient flow rate, determined by the inner section of the Massey

Ferguson 6465, 6470, 6499, 6495 spool valve, is supplied by the pump to

maintain the pressure difference at the spool valve terminals (22 bar).

Parts list

G - From charge pump

P - High pressure (HP) outlet to single priority block or hydraulic unit

with two priority blocks

R - To control piston (14)

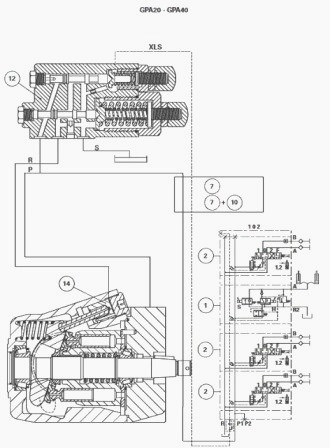

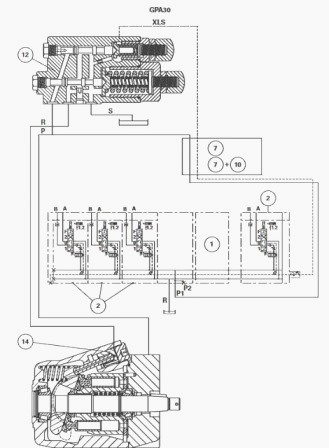

Parts list

(1) Linkage spool valve, (2) Auxiliary spool valves, (7) or [(7) and

(10)] Single priority block or hydraulic unit with two priority blocks

with or without trailer braking, (12) Variable displacement pump

hydraulic regulator, (14) Piston

Maximum position - zero flow rate

When the pressure at port P reaches 200 bar, spool "b" is pushed

forwards compressing its spring. The ports P and R are placed in

communication and piston (14) is brought to the zero flow rate position.

The hydraulic regulator (12), Installed on the hydraulic cover plate (8)

regulates the variable displacement pump pressure and flow rate

according to information transmitted by the LS signal. Screws C and D

are factory set. Do not modify these settings.

Legend

C - 22 bar adjustment screw

D - 200 bar adjustment screw

O - Decompression port

P - Variable displacement pump pressure

R - To piston (14)

S - Return

XLS Signal

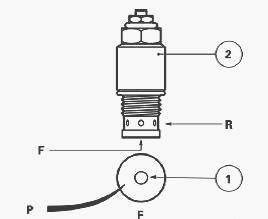

Pressure relief-valve (2)

The high pressure flow delivered by the variable displacement pump

passes through channel P in the hydraulic cover plate and is directed

towards the single priority block or to the hydraulic unit with two

priority blocks (depending on version).

The pressure relief valve (2) set to 230 bar ± 5 and screwed into the

hydraulic cover plate, ensures the safety of the high pressure (HP)

system.

In case of any abnormal increase in pressure, valve (1) raises and the

oil is directed to the housing via ports R in the relief valve.

Removing and install the variable

displacement hydraulic pump

Remove the Massey Ferguson 6290, 6270, 6490, 6280 tractor right-hand

hydraulic cover plate.

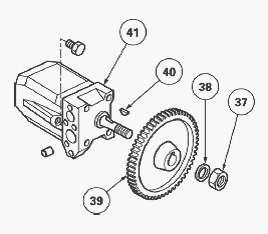

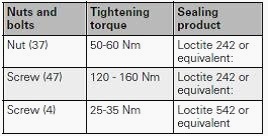

Immobilise the driven gear (39) of the variable displacement pump (41)

by inserting a bronze drift between this gear and the hydraulic cover

plate. Release and slightly loosen the nut (37).

Unscrew the screws that secure the variable displacement pump to the

hydraulic cover plate. Separate the pump from the cover plate.

Place the variable displacement pump (41) on a workbench. Completely

unscrew the nut (37). Recover the washer (38).

Using a suitable extractor, release and remove the driven gear (39) from

the tapered section of the shaft. Recover the key (40).

If necessary, remove the safety valve (45) from the Massey Ferguson

6465, 6470, 6499, 6495 low pressure system.

Reinstall

Clean the components. Replace those that are defective. Check that none

of the hydraulic cover plate channels are obstructed. Check the presence

of dowels (4). Replace the "O" rings (1) to (3).

Repeat the pump removal operations in reverse order. Inside the cover

plate, apply a small bead of Loctite 574 or equivalent around the holes

of screws (47) to seal these holes.

Apply the same method as used with the left-hand cover plate. Lightly

smear the thread of the engine speed sensor (25) (if fitted) with

Loctite 5922 or equivalent. Adjust the sensor.

Adjusting the MF 6290, 6270, 6490,

6280 engine speed sensor

Depending on the type of transmission, the LS right-hand hydraulic cover

plate (8) may or may not be fitted with an engine speed sensor. If a

sensor is fitted, adjust it by carrying out the following steps.

Manually tighten the sensor (25) home, without forcing it, until it

comes into contact with the teeth of the driven gear (39) of the

variable displacement pump.

Loosen the sensor by a ½ to ¾ turn to obtain approximately 1 mm

clearance between the sensor and the driven gear. Tighten the nut to 5-7

Nm without turning the sensor.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader