________________________________________________________________________________

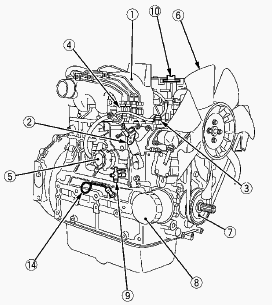

Kubota L2501, L3200, L3400, L3800 - Engine Service and Maintenance

Kubota L2501, L3200, L3400 tractors fitted with D1703 diesel engine.

D1803 engine used in L3800 model.

Kubota L2501, L3200, L3400, L3800 - Engine

Maintenance

Starting the Engine (normal)

Set the fuel lever to the "on" position. Place the engine stop lever to

the "Start" position. Place the speed control lever at more than half

"operation". Insert the key into the key switch and turn it to the

"operation" position. Turn the starter switch to the "preheating"

position to allow the glow lamp to redden. The glow lamp goes out in

about 5 seconds when the lamp timer is up. Even with the glow lamp off,

the glow plug can be preheated by turning the starter switch to the

"preheating" position. Turn the key to the "Starting" position and the

engine should start. Release the key immediately when a Kubota D1803

engine starts. Check to see that the oil pressure lamp and charge lamp

are off. If the lamps are still on, immediately stop the engine, and

determine the cause. If the oil pressure lamp should be still on,

immediately stop the engine and check. If there is enough engine oil. If

the engine oil has dirt in it. If the wiring is faulty. Warm up the

engine at medium speed without load. If the engine does not catch or

start at 10 seconds after the starter switch is set at "Starting"

position, wait for another 30 seconds and then begin the engine starting

sequence again. Do not allow the starter motor to run continuously for

more than 20 seconds.

Cold weather starting

If the ambient temperature is below -5C (23F) and the engine is very

cold, start it in the following manner: Set the fuel lever to the "ON"

position. Place the engine stop lever to the "Start" position. Place the

speed control lever at more than half "operation". Insert the key into

the key switch and turn it to the "operation" position. Turn the key to

the "preheating" position and keep it there for a certain period

mentioned below. Turn the key to the "Starting" position and the engine

should start. If the engine fails to start after 10 seconds, turn off

the key for 5 to 30 seconds. Do not allow the starter motor to run

continuously for more than 20 seconds. Be sure to warm up the engine,

not only in winter, but also in warmer seasons. An insufficiently

warmed-up engine can shorten its service life. When there is fear of

temperature dropping below -15 C (5 F) detach the battery from the

machine, and keep it indoors in a safe area, to be reinstalled just

before the next operation.

Radiator Cooling water

If the coolant temperature warning lamp lights up or if steam or coolant

does not stop squirting from the radiator overflow pipe, turn off the

load and keep the engine idling (Cooling-Down) for at least 5 minutes to

let it cool down gradually. Then stop the engine and take the following

inspection and servicing. Check to see if the coolant runs short or if

there is any coolant leak. Check to see if there is any obstacle around

the cooling air inlet or outlet. Check to see if there is any dirt or

dust between radiator fins and tube. Check to see if the fan belt is too

loose. Check to see if radiator water pipe is clogged.

Color of exhaust - While Kubota D1703 engine is run within the rated

output range: The color of exhaust remains colorless. If the output

slightly exceeds the rated level, exhaust may become a little colored

with the output level kept constant. If the engine is run continuously

with dark exhaust emission, it may lead to trouble with the engine.

Immediately stop the engine if: The engine suddenly slows down or

accelerates. Unusual noises are suddenly heard. Exhaust fumes suddenly

become very dark. The oil pressure lamp or the water temperature alarm

lamp lights up.

How to tell when the engine starts running backwards - Lubricating oil

pressure drops sharply. Oil pressure warning light, if used, will light.

Since the intake and exhaust sides are reversed, the sound of the engine

changes, and exhaust gas will come out of the air cleaner. A louder

knocking sound will be heard when the engine starts running backwards.

Remedies - Immediately set the engine stop lever to the "Stop" position

to stop Kubota D1803 engine. After stopping the engine, check the air

cleaner, intake rubber tube and other parts, and then replace parts as

needed.

Air bleeding the fuel system

Air bleeding of the fuel system is required if: After the fuel filter

and pipes have been detached and refitted; after the fuel tank has

become empty; or before the engine is to be used after a long storage.

Fill the fuel tank to the fullest extent. Open the fuel filter lever.

Open the air vent cock on top of the fuel injection pump. Turn the

engine, continue it for about 10 seconds, then stop it, or move the fuel

feed pump lever by hand (optional). Close the air vent cock on top of

the fuel injection pump. Always keep the air vent cock on the fuel

injection pump closed except when air is vented, or it may cause the

engine to stop. For fuel tanks that are lower than the injection pump.

The fuel system must be pressurized by the fuel system electric fuel

pump. If an electric fuel pump is not used, you must manually actuate

the pump by lever to bleed. The primary fuel filter must be on the

pressure side of the pump if the fuel tank is lower than the injection

pump. To bleed, follow through above. Tighten air vent plug of the fuel

injection pump except when bleeding, or it may stop the engine suddenly.

Checking the fuel pipes

Check the fuel pipes every 50 hours of operation. If the clamp band is

loose, apply oil to the screw of the band, and tighten the band

securely. If the fuel pipes, made of rubber, become worn out, replace

them and clamp bands every 2 years. If the fuel pipes and clamp bands

are found worn or damaged before 2 years pass, replace or repair them at

once. After replacement of the pipes and bands, air-bleed the fuel

system. When the fuel pipes are not installed, plug them at both ends

with clean cloth or paper to prevent dirt from entering. Dirt in the

pipes can cause fuel injection pump malfunction.

Kubota L2501, L3200, L3400, L3800 - Cleaning

the fuel filter pot

Every 100 hours of operation, clean the fuel filter in a clean place to

prevent dust intrusion. Close the fuel filter lever. Remove the top cap,

and rinse the inside with diesel fuel. Take out the element, and rinse

it with diesel fuel. After cleaning, reinstall the fuel filter, keeping

out of dust and dirt. Air-bleed the injection pump. Entrance of dust and

dirt can cause a malfunction of the fuel injection pump and the

injection nozzle. Wash the fuel filter cup periodically.

Fuel filter cartridge replacement

Replace the fuel filter cartridge with a new one every 400 operating

hours. Apply fuel oil thinly over the gasket and tighten the cartridge

into position by hand-tightening only. Finally, vent the air. Replace

the fuel filter cartridge periodically to prevent wear of the fuel

injection pump plunger or the injection nozzle, due to dirt in the fuel.

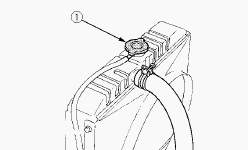

Checking oil level and adding engine oil

Check the engine oil level before starting or more than 5 minutes after

stopping Kubota D1803 engine. Remove the oil level gauge, wipe it clean

and reinstall it. Take the oil level gauge out again, and check the oil

level. If the oil level is too low, remove the oil filler plug, and add

new oil to the prescribed level. After adding oil, wait more than 5

minutes and check the oil level again. It takes some time for the oil to

drain down to the oil pan. Engine oil capacity - 7.5-9.5 L.

Changing engine oil

Change oil after the initial 50 hours of operation and every 200 hours

thereafter. Remove the drain plug at the bottom of the engine, and drain

all the old oil. Drain oil will drain easier when the oil is warm. Add

new engine oil up to the upper limit of the oil level gauge.

Replacing the oil filter cartridge

Replace the oil filter cartridge. Apply a film of oil to the gasket for

the new cartridge. Screw in the cartridge by hand. When the gasket

contacts the seal surface, tighten the cartridge enough by hand.

Because, if you tighten the cartridge with a wrench, it will be

tightened too much. After the new cartridge has been replaced, the

engine oil level normally decreases a little. Thus, run the engine for a

while and check for oil leaks through the seal before checking the

engine oil level. Add oil if necessary.

Kubota L2501, L3200, L3400, L3800 - Checking

coolant level, adding coolant

Remove the radiator cap, after the engine has completely cooled, and

check to see that coolant reaches the supply port. If the radiator is

provided with a recovery tank, check the coolant level of the recovery

tank. When it is between the "Full" and "Low" marks, the coolant will

last for one day's work. When the coolant level drops due to

evaporation, add water only up to the full level. Check to see that two

drain cocks; one is at the crankcase side and the other is at the lower

part of the radiator. If the radiator cap has to be removed, follow the

caution and securely retighten the cap. If coolant should be leak,

repair it or replace. Make sure that muddy or sea water does not enter

the radiator. Use clean, fresh water and 50% anti-freeze to fill the

recovery tank. Do not refill recovery tank with coolant over the "Full"

level mark. Be sure to close the radiator cap securely. If the cap is

loose or improperly closed, coolant may leak out and decrease quickly.

Remedies for quick decrease of coolant

Check any dust and dirt between the radiator fins and tube. If any,

remove them from the fins and the tube. Check the tightness of the fan

belt. If loose, tighten it securely. Check the internal blockage in the

radiator hose. If scale forms in the hose, clean with the scale

inhibitor or its equivalent.

Checking radiator hoses and clamp bands

Check to see if radiator hoses are properly fixed every 200 hours of

operation or 6 months, whichever comes first. If hose clamps are loose

or water leaks, tighten hose clamp securely. Replace hoses and tighten

hose clamps securely, if radiator hoses are swollen, hardened or

cracked. Replace hoses and hose clamps every 2 years or earlier, if

checked and found that hoses are swollen, hardened or cracked. If the

coolant temperature warning lamp lights up or if steam or coolant does

not stop squirting from the radiator overflow pipe, turn off the load

and keep the engine idling (Cooling-Down) for at least 5 minutes to let

it cool down gradually. Then stop the engine and take the following

inspection and servicing. Check to see if the coolant runs short or if

there is any coolant leak. Check to see if there is any obstacle around

the cooling air inlet or outlet. Check to see if there is any dirt or

dust between radiator fins and tube. Check to see if the fan belt is too

loose. Check to see if radiator water pipe is clogged.

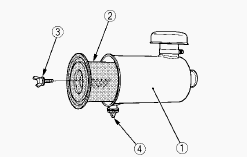

Air cleaner

Since the air cleaner employed on this engine is a dry type, never apply

oil to it. Open the evacuator valve once a week under ordinary

conditions - or daily when used in a dusty place. This will get rid of

large particles of dust and dirt. Wipe the inside air cleaner clean with

cloth if it is dirty or wet. Avoid touching the element except when

cleaning. When dry dust adheres to the element, blow compressed air from

the inside turning the element. Pressure of compressed air must be under

205 kPa (2.1 kgf/cm2, 30 psi). Replace the element every year or every 6

cleanings. Make sure the wing bolt for the element is tight enough. If

it is loose, dust and dirt may be sucked in, wearing down the cylinder

liner and piston ring earlier and thereby resulting in poor power

output. Do not over service the air cleaner element. Over servicing may

cause dirt to enter the engine causing premature wear. Use the dust

indicator as a guide on when to service. Evacuator valve - Open the

evacuator valve once a week under ordinary conditions - or daily when

used in a dusty place - to get rid of large particles of dust and dirt.

For the air cleaner with a dust cup (optional) - Remove and clean out

the dust cup before it becomes half full with dust; usually once a week,

or even every day if the working surroundings are dusty. Install the air

cleaner dust cup with "top" indicated on the rear of the cup in the up

position. (However, it may be installed in either direction when the

cover is placed at the lower part.). If the dust cup is mounted

incorrectly, dust or dirt does not collect in the cup, and direct

attachments of the dust to the element will cause its lifetime to

shorten to a great extent.

Adjusting Fan Belt Tension

Stop the engine and remove the key. Apply moderate thumb pressure to

belt between the pulleys. If tension is incorrect, loosen the alternator

mounting bolts and, using a lever placed between the alternator and the

engine block, pull the alternator out until the deflection of the belt

falls within acceptable limits. Replace fan belt if it is damaged. If

belt is loosen or damaged and the fan is damaged, it could result in

overheats or insufficient charging. Correct or replace belt.

Kubota L2501, L3200, L3400, L3800 - Service

Engine

Top Clearance

Remove the cylinder head. With the piston at TDC, use grease to affix

three or four plastigauges of a diameter 1.5 mm (0.059 in.) x 5.0 to 7.0

mm (0.20 to 0.27 in.) long to the crown of the piston; keep the gauges

away from the intake valve and combustion chamber fittings. Take the

piston to an intermediate position, install the cylinder head and

tighten the head screws to the specified torque. Turn the crankshaft so

the piston goes through TDC. Remove the cylinder head and compare the

width of the crushed plastigauges with the scale. If they are out of

spec, check the oil clearance of the crank pin, journals and piston pin.

Top clearance - 0.60 to 0.70 mm / 0.024 to 0.027 in.

Valve Seating

Apply a thin layer of Prussian Blue on the valve face. Then put the

valve on its seat to examine the contact. If the valve is not fully

around the seat or the contact is less than 70 % of the factory

specification, correct the valve seat. If the valve contact width cannot

get the factory specification, replace the valve or correct the contact

of the valve seat. Valve contact width - 2.12 mm / 0.0835 in.

Timing Gear Backlash

Set a dial indicator (lever type) with its point on the gear tooth. Hold

the mating gear and move the gear to measure the backlash. If the

backlash is more than the allowable limit, measure the oil clearance in

the journal part of each shaft. If the oil clearance is correct, replace

the gear. Backlash between idle gear and crank gear - 0.04150 to 0.1122

mm / 0.001634 to 0.004417 in. Backlash between idle gear and cam gear -

0.04150 to 0.1154 mm / 0.001634 to 0.004543 in. Backlash between idle

gear and fuel supply pump gear - 0.04150 to 0.1154 mm / 0.001634 to

0.004543 in. Backlash between crank gear and oil pump gear - 0.04150 to

0.1090 mm / 0.001634 to 0.004291 in.

Replacement of Small End Bushing

Press out the used small end bushing with the replacing tool. Clean a

new small end bushing and bore, and apply engine oil to them. Make sure

that the oil hole of the connecting rod aligns the bushing hole. Then

press fit the new bushing with the replacing tool.

Connecting Rod Alignment

Make sure that the oil clearance of the small end bushing is less than

the allowable limit. Install the piston pin into the connecting rod.

Install the connecting rod on the alignment tool of the connecting rod.

Put a gauge on the piston pin, and move it against the face plate. If

the gauge does not touch fully against the face plate, measure the space

between the gauge pin and face plate. If the measurement is more than

the allowable limit, replace the connecting rod. Connecting rod

alignment - Allowable limit 0.05 mm / 0.002 in.

Side Clearance of Crankshaft

Set a dial indicator with its point on the end of the crankshaft. Move

the crankshaft to the front and rear to measure the side clearance. If

the measurement is more than the allowable limit, replace the thrust

bearings. If the same dimension bearing is not applicable because of the

crankshaft journal wear, replace it with an oversize one. Side clearance

of crankshaft - 0.15 to 0.31 mm / 0.0059 to 0.012 in.

Crankshaft Bend

Hold the 2 end journals of crankshaft with V blocks on the surface

plate. Set a dial indicator with its point on the middle journal. Turn

the crankshaft slowly and read the variation on the indicator. If the

measurement is more than the allowable limit, replace the crankshaft.

Crankshaft bend - Allowable limit 0.03 mm / 0.001 in.

Kubota L2501, L3200, L3400, L3800 - Engine

Troubleshooting

Engine is difficult to start or won't start

No fuel flow - Check the fuel tank and the fuel filter. Replace filter

if necessary.

Air or water is in the fuel system - Check to see if the fuel line

coupler bolt and nut are tight. Bleed the fuel system.

In winter, oil viscosity increases, and engine revolution is slow - Use

oils of different viscosities, depending on ambient temperatures. Use

engine block heater (Optional).

Battery becomes weak and the engine does not turn over quick enough -

Clean battery cables and terminals. Charge the battery. In cold weather,

always remove the battery from the engine, charge and store it indoors.

Install it on the tractor only when the tractor is going to be used.

Insufficient engine power

Insufficient or dirty fuel - Check the fuel system.

The air cleaner is clogged - Clean or replace the element.

Kubota D1703 engine stops suddenly.

Insufficient fuel. Refuel. Bleed the fuel system if necessary.

Exhaust fumes are black colored

Fuel quality is poor - Change the fuel and fuel filter.

Too much oil - Check the proper amount of oil.

The air cleaner is clogged - Clean or replace the element.

Exhaust fumes are blue or white colored

The inside of exhaust muffler is dumped with fuel - Heat the muffler by

applying load to the engine.

Injection nozzle trouble - Check the injection nozzle.

Fuel quality is poor - Change the fuel and fuel filter.

Kubota D1803 engine overheats

Engine overloaded - Shift to lower gear or reduce load.

Low coolant level Fill cooling system to the correct level; check

radiator and hoses for loose connections or leaks.

Loose or defective fan belt - Adjust or replace fan belt.

Dirty radiator core or grille screens - Remove all trash.

Coolant flow route corroded - Flush cooling system.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES INSTRUCTIONS

INSTRUCTIONS PROBLEMS

PROBLEMS B2320

B2320 B2630

B2630 B2920

B2920 B3300SU

B3300SU BX2360

BX2360 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 BX2660

BX2660 L2501

L2501 L3240

L3240 L3540

L3540 L3940

L3940 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 L4400

L4400 L4600

L4600 L5040

L5040 L5740

L5740 MX4700

MX4700 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 B2710

B2710 BX23S

BX23S B3350

B3350 BX1880

BX1880 L4701

L4701 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 M100GX

M100GX M135GX

M135GX M6040

M6040 M8540

M8540 M95X

M95X LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 M5-091

M5-091 BX2680

BX2680 MX5200

MX5200 BX2380

BX2380 L3901

L3901 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605