________________________________________________________________________________

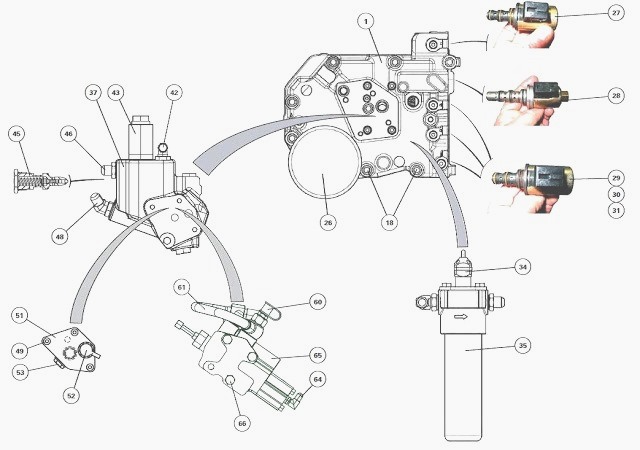

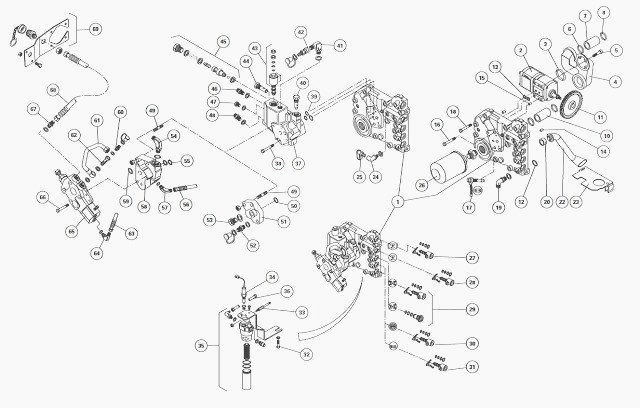

MF 5611, 5455 series tractors hydraulic system - Right-hand cover plate

The Massey Ferguson 5400-5600 series

tractors right-hand cover plate (hydraulic system 100 l/min) is fitted

to the rear axle housing and has two main functions:

- it supports numerous hydraulic system components,

- it incorporates the various suction and distribution channels of the

high flow rate system.

On its internal face, the cover plate is connected to the:

- hydraulic pumps of the high flow rate system and their drive gear

- suction pipe

- inlet manifold

- the left-hand cover plate transfer pipe.

On its external faces, it is connected to the:

- four or five control solenoid valves of the low pressure functions.

- There is a diode in the solenoid of the PTO brake solenoid valve.

- The MF 5612, 5445 PTO clutch is controlled by an on/off solenoid

valve.

- safety valve in the high flow rate system

- trailer brake valve (if fitted) or a cover plate (depending on option)

- two "diagnostics" connectors,

- suction strainer

- 15 micron main filter and support

- filter switch

- engine speed sensor

- pump coupling unit and coupling solenoid valve.

Parts list

(1) Right-hand hydraulic cover plate (2) Pump (3) Seal (4) Suction

manifold (5) Screw (6) Seal (7) Transfer pipe (8) Seal (9) Restrictor

(10) Transfer pipe (11) Gear

(12) Seal (13) "O" ring (14) Pin (15) Centring pin (16) Screw (17)

Engine speed sensor (18) Screw (19) Elbow union (20) Seal

(21) Pin (22) Pipe (23) Plate (24) Elbow union (25) Pressure connector

(26) Filter (27) PTO brake solenoid valve (28) PTO clutch solenoid valve

(29) Front axle

clutch solenoid valve (or plug) depending on option (30) Differential

lock solenoid valve (31) Hare / Tortoise (Hi / Lo) solenoid valve

(32) Support (33) Spacer (34) Pressure switch (35) 15 micron filter (36)

Pipe (37) Selection unit (38) Screw (39) Seals (40) Non-return valve

(41) Elbow union (42)

Pressure connector (43) Coupling solenoid valve (44) Non-return valve

(45) 200 bar pressure relief valve (46) Union

(47) Plug (48) Union (49) Stud (50) Seal (51) Cover plate (52) Pressure

connector (53) Plug (54) Elbow union (55) Seals (56) Hose (57) Elbow

union (58) Support

(59) Seal (60) Pressure connector (61) Pipe (62) Union (63) Hose (64)

Elbow union (65) Trailer brake spool valve (66) Screw (67) Union

(68) Hose (69) Trailer brake connector

Removing and install the cover plate

Immobilise the MF 5612, 5611 tractor. Chock the left rear wheel. Apply

the hand brake.

Chock between the frame and the front axle (optional).

Partially drain the rear axle housing. Take off the wheel concerned.

Place an axle stand in position.

Removal

Disconnect the blockage indicator harness.

Remove the 15 micron filter and its support (32).

Remove the strainer to access the partially hidden screw.

If the tractor is fitted with a trailer brake mechanism: Remove the

spool valveand support.

Disconnect and block:

- the hose to the auxiliary system,

- the pipe to the linkage spool valve,

- the rear differential lock pipe and the hose from the front

differential lock control (if fitted),

- the 4WD clutch supply pipe for tractors fitted with this option,

- the Massey Ferguson 5445, 5455 tractor PTO brake supply pipe,

- the steering spool valve supply pipe via the 15 micron filter,

- the 17 bar hydraulic cover plate supply pipe.

Disconnect the harness of the engine speed sensor (17) and filter

switch.

Disconnect solenoid valves (27) to (31), marking their connections.

The function of each solenoid valve is indicated on the external face of the hydraulic cover plate casing. The cover plate is fitted with two different types of solenoid valves.

The solenoid valve (27) of the PTO brake has a solenoid with a

diode and is represented

by the following symbol (+/-).

Remove the screws (18) and the cover plate (1).

After removing the cover plate, if necessary, remove the transfer pipe

(7) from the housing, ensuring hydraulic continuity to the pump

manifold.

Install

Clean the mating faces of the housing and cover plate.

Check for the presence of the two centring pins (14) and rivets at the

ends of the channels on the Massey Ferguson 5611, 5612, 5445, 5455 cover

plate.

Install new seals:

- on the Hare / Tortoise channels,

- on the power take-off clutch channel.

Install and position the suction pipe, with its notch along the axis of

the pin (21). Position the seal (20).

Screw two makeshift guide studs into opposing holes on the housing.

Install the transfer pipe (if removed), first checking the seals are in

a good condition.

Smear the mating faces of the cover plate with a sealing product

(Loctite 510 or equivalent) taking

care not to block the hydraulic ports of the Hare / Tortoise mechanism.

Reinstall the cover plate. Take out the guide studs. Install and tighten

the cover plate screws to a torque of 72 - 96 Nm.

Reconnect (in accordance with the markings made):

- solenoid valves (27) to (31),

- filter switch

- engine speed sensor (17).

Attach the electrical harnesses with a retainer.

Reconnect the pipes and hoses.

Reinstall the trailer brake spool valve (65) and support (58).

Check the condition of the seal of the strainer (26) and lubricate it.

Install the strainer and tighten it an additional quarter turn after it

contacts with the seal. Install the

15 micron filter (35) and its support (32). Reconnect the blockage

indicator (34).

Lift the Massey Ferguson 5612, 5611 tractor. Install the wheel. Remove

the axle stand and tighten the nuts. Remove the chocks.

Top up the transmission oil level of the rear axle and check it using

the gauge located to the rear of the centre housing.

Check the operation of the electrical circuits, the low pressure switch,

the solenoid valves, the filter switch and the blockage indicator.

If the pump has been replaced, or if the disassembly of one or several

hydraulic component(s) was necessary, check the hydraulic system by

carrying out the

relevant tests.

Check the tightness of the cover plate mating face, the strainer and the

hydraulic unions.

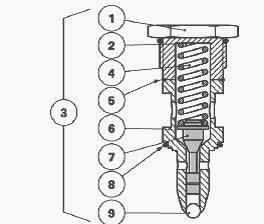

Disassembling and reassembling the high pressure valve

Operation - If pressure "P" rises above 200 bar ± 5 bar, the spring (4)

is compressed, opening the valve (7) to allow oil to pass into the

housing via port R.

Preliminary step - If necessary, take off the right-hand rear wheel.

Position a safety stand.

Disassembly

To facilitate valve access, disconnect and plug the linkage valve and

spool valve supply hoses.

Unscrew the plug (1). Recover the shims (2) and take out the spring (4).

Remove the "O" ring (5), extract the body (6) with the valve (7) and the washer (8) from the right-hand cover plate.

The ball bearing (9) is

crimped in the body of the

valve.

Reassembly

Check that the valve (7) slides freely in the valve body (6).

Place the washer (8), Install the valve body (6) with the valve (7) into

the cover plate. Position the "O" ring (5).

Install the spring (4), the shims (2) and tighten the plug (1) to a

torque of 70 - 100 Nm. Reinstall the linkage valve and spool valve

hoses.

Reinstall the wheel (if removed). Tighten nuts.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader