________________________________________________________________________________

Massey Ferguson 5430, 5440 gearbox - Intermediate Shaft

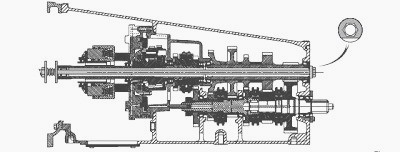

The intermediate shaft and its gears form the upper shaftline of the MF

5430, 5440 gearbox with mechanical reverse shuttle (GBA20). It supports

the 1st to 4th driven gears. The shaft rear teeth (54) are constantly

meshed with the Tortoise gear.

The shaft is supported by:

- the tapered roller bearing (63) and (64) housed in the rear bearing of

the input unit;

- the tapered roller bearing (52) and (53) located in the rear bearing

of the gearbox.

The four gears are held in position by the spacers (57) and (82). The

operating clearance for these gears is obtained by inserting the shims

(58) between the 1st

(60) and 2nd (59) driven gears.

(50) Oil deflector (51) Shim(s) (52) Bearing cup (53) Bearing cone (54)

Shaft (55) 3rd driven gear (56) 4th driven gear (57) Spacer (58) Shim(s)

(59) 2nd driven gear

(60) 1st driven gear (61) Circlip (62) Needle roller bearing (63)

Bearing cone (64) Bearing cup (82) Spacer

To correctly shim the intermediate shaft tapered roller bearings, it is

necessary to remove the gearbox.

Split the Massey Ferguson 5430, 5440 tractor between the gearbox and the

rear axle. Split the gearbox from the engine. Place the gearbox on a

workbench or a

suitable support.

Remove the selector cover plate. Remove the input

unit. After removing the input unit, pair the bearing cup housed in the

input unit rear bearing

with the intermediate shaft front bearing cone.

Removing and install the shaft and gear assembly

Remove the oil deflector (50) using a slide hammer puller and remove the

shims (51) and the cup (52) to release the rear end of the shaft.

Take the shaft and gear assembly out through the front of the housing,

by tilting it so that the gears are released from the lower shafts.

When removing the shaft, do not insert the handling bar in the bore as

this will damage the needle roller bearing (62).

If necessary, carry out the operation with the help of an assistant.

Clean and check all components.

Replace those that are defective. In the housing, position the assembled

shaft with its related gears.

If necessary, check and correct the shimming of the shaft. Otherwise,

refit the cup, the original shims and the oil deflector (50).

Removing and install the gears

Extract the bearing cone (63). Remove circlip (61) by opening it up as

little as possible.

Remove 2nd gear (59), shims (58), 1st gear (60) and spacer (57).

Remove 4th gear (56), spacer (82) and 3rd gear (55). Clean and check all

components.

Replace those that are defective. Install the 3rd gear (55), spacer (82)

and 4th gear (56).

Install the spacer (57). Fit the 1st gear (60) and the 2nd gear (59),

temporarily without the shims (58).

Install the circlip (61). Shim the gears. Install the shaft, assembled

with its related gears, in the housing.

Replacing the tapered roller bearings of the intermediate shaft

Remove the shaft (54) and gear assembly. Extract the bearing cones (53)

and (63). Discard them. If necessary, replace the shaft.

If the shaft (54) has been replaced: Using a suitable fixture and a

press, fit a new needle roller bearing (62) thrust up against the

shoulder of the shaft.

Check needle rotation after assembly. Reassemble the gears.

Install bearing cones (63) and (53) using a press and a suitable

fixture.

Position the shaft, assembled with its related gears, into the housing.

Shim the shaft.

Shimming the gears

The gears should be stacked temporarily without the shims (58).

Using a set of shims, measure the space between the 1st gear (60) and

the 2nd gear (59).

Depending on the measured distance, choose shim(s) of an appropriate

thickness to obtain the clearance J1 = 0 to 0.25 mm.

Remove the circlip (61), opening it up as little as possible, and remove

the gear (59).

Slide the previously selected final shims onto the shaft. Refit the gear

and position the circlip correctly.

Install bearing cone (63). Install the shaft, assembled with its related

gears, in the housing.

Shimming the shaft

To carry out shimming on the intermediate shaft, the input unit must be

refitted. Carry out the shimming on the shaft to obtain a clearance of

J2 = 0 to 0.08 mm.

Install the makeshift tool in the shaft. Slightly compress the spring,

while tightening the nut of the tool, to correctly seat the bearing

cones in their cups.

Rotate the shaft a few turns. Check spring compression again. Using a

depth gauge, measure dimension X between face A of the bearing cup (52)

and face B of

the housing. Measure the thickness Y of the oil deflector (50).

Calculate the difference between X and Y.

Determine the thickness of shims required to obtain the clearance J2. If

possible, shim to the minimum tolerance.

Remove the compression tool.

Install the oil deflector in the housing. Install the input unit.

Install the selector cover plate.

Attach a sling to the gearbox. Lower it from the workbench or suitable

support.

Reconnect the MF 5430, 5440 tractor gearbox and the engine. Reconnect

the tractor between the gearbox and the rear axle.

Check:

- tightness of the hydraulic systems;

- correct operation of electrical circuits.

Carry out a road test of all controls. Check the tightness of the unions

and mating faces (selector cover plate, gearbox on rear axle).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader