________________________________________________________________________________

Massey Ferguson 5455, 5440 tractor gearbox- Output shaft

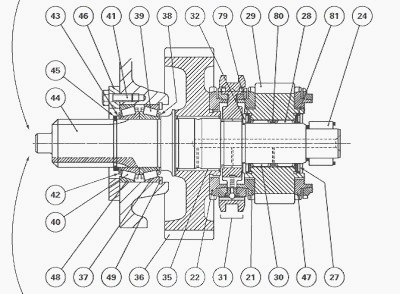

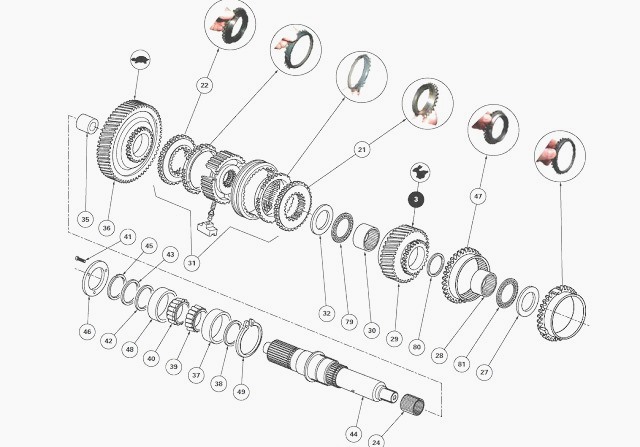

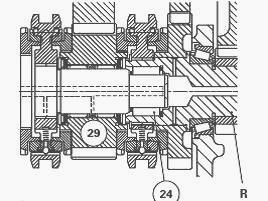

The bearings (28) (30) separated by a spacer (80) rotate the driving gear (29) on the output shaft. The bearings (79) (81) operate as axial stops. A single cone synchroniser allows range shifting between gears (29) (Hare) and (36) (Tortoise).

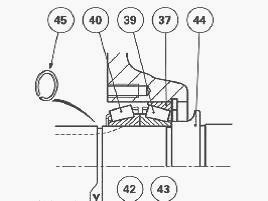

Preloading, or the clearance between the cones (39) (40) and their

respective cups (48) (37) is adjusted according to the thickness of the

circlip (49).

The output shaft transmits movement from the different ratios to the

rear axle transfer shaft. It is fitted on the lower transmission line at

the rear of the unit. It is supported at the front by a needle roller

bearing fitted in the layshaft bore and at the rear by two opposing

tapered roller bearings.

The shaft (44) supports:

- the driving gear (29) fitted idle onto the combined bearings (28)

(30);

- the idle-fitted gear (36) and ring (35) assembly;

- the Hare/Tortoise synchroniser (31), integral rotation by splines.

To ensure correct operation of the assembly depending on the load

applied to the MF 5440, 5455 transmission, several adjustments are

required:

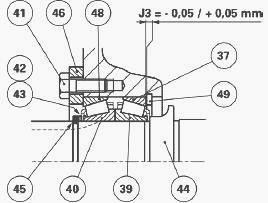

- Shimming J3: via the circlip (49), this shimming cancels out the

clearance between the cones (39) (40) and their respective cup.

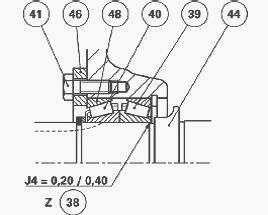

- Shimming J4: the shim(s) (38) positioned between the shoulder of the

shaft (44) and the cone (39) provide axial clearance for the gear (29).

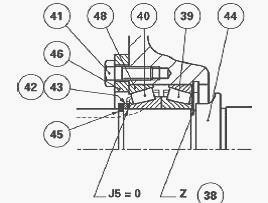

- Shimming J5: the shim(s) (42) fitted between the cone (40) and the

shim (43) cancel out the axial clearance of the cones (39) (40) on the

shaft (44).

The GBA20 gearbox output shaft without creeper gears may be replaced by

two other shafts relating to the following options respectively: creeper

unit or super

creeper unit.

(21) Synchroniser cone (Hare) (22) Synchroniser cone (Tortoise) (24)

Needle roller bearing (27) Thrust washer (28) Needle roller bearing (29)

3rd driving gear

(Hare) (30) Needle roller bearing (31) Hare / Tortoise single cone

synchronizer (32) Thrust washer (35) Ring (36) Tortoise gear (37)

Bearing cup (38) Shim(s) (39)

Bearing cone (40) Bearing cone (41) Screw (42) Shim(s) (43) Shim (44)

Output shaft (45) Circlip (46) Stop plate (47) 3rd synchroniser cone

(48) Bearing cup (49)

Circlip (79) Needle roller bearing (80) Spacer (81) Needle roller

bearing

Disconnect the Massey Ferguson 5455, 5440 tractor between the gearbox

and the rear axle. Remove the selector cover plate. If necessary, remove

the screw.

Disassembling and reassembling the selector rail and the forks

The MF 5455, 5440 tractor is disconnected. Consequently, selector rail

removal is made easier by this separation which is to be made from the

rear side of the

gearbox housing. Apart from this point, the procedure remains unchanged.

If the tractor is fitted with a creeper unit, remove the pin, the

counter-nut, the adjustable lock, and the fork with the sleeve. If the

tractor is fitted with a super-creeper

unit, the fork and its lock are removed as described above, except for

the absence of the pin.

Remove the selector rail and the forks. Clean and check all components.

Replace those that are defective. Install the selector rail and the

forks. Depending on the

equipment, refit the sleeve, fork, adjustable lock and pin. To adjust

the fork.

Disassembling, reassembling and shimming the shaft

If the Massey Ferguson 5440, 5455 tractor is fitted with a creeper unit

or super-creeper unit, remove the unit. The bearing cones and cups are

to be paired if reused.

Remove the screws (41). Remove the stop plate (46). Remove the bearing

cup (48). Remove the circlip (45).

Remove the shim (43) and the shims (42). Remove the bearing cones (40)

(39). Remove the shims (38) and the cup (37). Remove the circlip (49).

Pull and remove

the shaft (44) backwards while holding the gear assembly.

Through the selector cover plate opening, take out:

- the synchroniser (31) and its rings;

- the Hare / Tortoise synchroniser cones (21) and (22);

- the gear assembly (29) and needle roller bearings (28) (30);

- the cone (47) and the 3rd synchroniser ring;

- the two needle roller bearings (79) (81);

- the thrust washers (27) (32). The synchroniser cones and rings are to

be paired if reused.

If necessary, remove the Tortoise gear (36). If work is necessary on

this gear, first remove the input unit in order to lift the gearbox

intermediate shaft to take out the

gear concerned through the selector cover plate opening. Remove the

needle roller bearing (24), while marking the assembly direction.

Check and clean all components. Replace those that are defective.

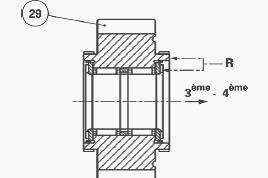

Position the needle roller bearing (24) in the bore of the layshaft "R",

taking care to position the

smaller diameter of the flexible ring towards the 3rd driving gear

(Hare) (29).

Install the shaft in the housing without the gears. Install a temporary

circlip (49), minimum thickness. Position the cup (37).

Slide cones (39) (40) and hold them against the shoulder of shaft (44)

by applying pressure by hand. Fill space Y between the rear of cone (40)

and the groove of

circlip (45) with shims (42) and shim (43) which will be placed against

circlip (45). Take a new circlip.

The circlip must be held closed in the groove under a slight pressure.

Install the cup (48) and the stop plate (46). Tighten screws (41) to a

torque of 25 - 35 Nm. For

gearboxes fitted with a creeper unit, use the unit plate to replace the

stop plate (46). Tighten the screws to a torque of 33.8 - 51.5 Nm.

Put the dial gauge feeler pin against the end of the shaft (44). Push

the shaft, while turning it alternately from right to left to correctly

"seat" the cones in the cups.

Set the dial gauge to zero. If the axial clearance is greater than 0.05

mm, set a definitive thickness of the circlip (49), to obtain J3 = -0.05

to +0.05 mm.

Remove the circlip (45). Remove the shim (43) and the shims (42). Remove

the screws (41) and the stop plate (46).

Remove: the cup (48); the bearing cones (40) (39), pairing them with

their cups; the cup (37); the temporary circlip (49) fitted; the shaft

(44).

Assembling the gears and the shaft

On the workbench, pre-assemble the 3rd driving gear (29) with the

synchroniser cones (21) and the 3rd gear (47) fitted with their

respective synchronizer ring. Fit

the bearings (79) (81) and washers (27)(32).

If removed, position the Tortoise gear (36) with its synchroniser ring

(22) into the housing. If the ring (35) of the Tortoise gear (36) is

damaged, replace the gear

assembly (the ring is rebored after fitting). Install the input unit.

In the housing, continue to fit:

- the 3rd driving gear (29) fitted with the needle roller bearings (28)

(30) (recess "R" facing towards the 3rd-4th synchroniser (Fig.6));

- the synchroniser (31). The needle roller bearings (28) (30) are

force-fitted and are separated by a spacer (80).

Install the output shaft (44) while holding the gear assembly.

Install the circlip (49) defined. Slide the cones and cups paired.

Install the stop plate (46). Tighten screws (41) to a torque of 25 - 35

Nm.

For MF 5440, 5455 gearboxes fitted with a creeper unit, use the unit

plate to replace the stop plate (46).

Tighten the screws to a torque of 33.8 - 51.5 Nm. Put the dial gauge

feeler pin against the end of the shaft (44).

Push the shaft, while turning it alternately from right to left to

correctly "seat" the cones in the cups.Set the dial gauge to zero.

Depending on the value read on the dial gauge, determine the thickness

of shims Z (38) to obtain: J4 = 0.20 to 0.40 mm.

Remove the screws (41) and the stop plate (46). Remove the cup (48).

Remove cones (40) (39).

Slide the required thickness of shims Z (38), and cones (39) (40) onto

the shaft.

Carry out shimming to obtain the clearance J5 = 0. Using the thickness

of shims Y (42) (43), determine the thickness of shims Z (38) to obtain

the clearance J5 = Y

- Z. Install the cup (48) and the stop plate (46). Tighten screws (41)

to a torque of 25 - 35 Nm.

Slide the thickness of shims. Position the shim (43) on the circlip

groove side. Position the circlip (45): it must be held closed in the

groove under slight pressure.

Check that it is correctly positioned.

Install the creeper or super creeper Massey Ferguson 5455, 5440 gearbox

(depending on option). Manually check the rotation of the shaft and its

gears. Install the

forks and the selector rail. Install the selector cover plate, by first

checking for the presence of the screw.

Reconnect the tractor between the gearbox and the rear axle. Check: the

tightness of the systems; correct operation of electrical circuits.

Carry out a road test of

the controls. Check the tightness of the mating faces (selector cover

plate, gearbox on rear axle).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader