________________________________________________________________________________

Massey Ferguson 5455, 5470 power shuttle gearbox – Shuttle

The Power Shuttle consists of two electrohydraulically controlled clutches. It is designed to enable direction of travel reversal under load.

The Power Shuttle transmits the drive from the engine to the layshaft

mounted on the front of the main gearbox by means of gears located

respectively at the rear of the unit and at the gearbox input. A lever

located to the left under the steering wheel, controls the Power

Shuttle.

Depending on the position selected by the operator (forward, neutral,

reverse), the lever manages the proportional solenoid valves of the

forward and reverse clutches by means of the Massey Ferguson 5455, 5470

tractor electronic system.

The solenoid valves are located at the front and to the right of the

gearbox on a clutch unit containing the Speedshift hydraulic control

system.

A filter element (60 microns) located under the selector cover plate,

upstream from the clutch unit, provides additional filtering of oil

supplying the solenoid valves (clutches, Speedshift). A potentiometer

sensor screwed to the gearbox housing sends information on shaft

rotational speed to the electronic system.

Shifting of any forward ratio to the corresponding reverse ratio, or

vice versa, is easy without declutching or stopping the tractor.

This "assisted" reversal enables gradual changing of the operating

direction, even at high travel speeds without abrupt changes in speed.

The clutches slow down tractor movement until the required speed is

reached so that the direction of travel can be reversed.

The conventional hydraulically operated clutch pedal is replaced by an

electrohydraulically operated manoeuvring pedal. This pedal modulates

the pressure in the forward or reverse clutches through the MF 5455,

5470 tractor electronic system and thus facilitates precise movements

such as implement hitching.

The forward and reverse clutches of the Power Shuttle are of different

design.

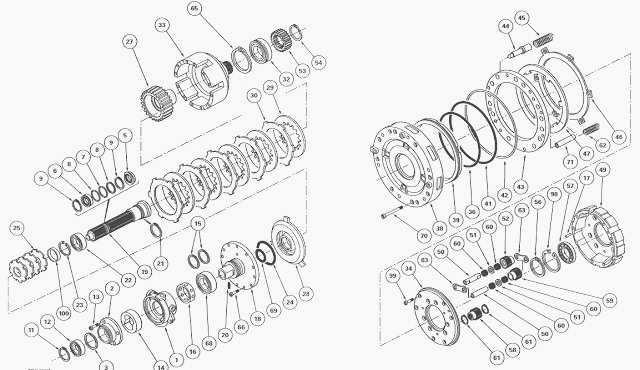

Forward clutch

The forward clutch consists of:

- a conventional multidisc wet clutch consisting of a bell (33), the

rear face of which is splined to assemble the input sun gear (53);

- an input shaft (19) crossing the spacer (4) which separates the engine

flywheel from the transmission oil.

- The shaft is constantly meshed with the damper secured to the engine

flywheel.

- It is splined so as to rotate with the clutch unit (18) which

comprises the intermediate plates (30) and the discs (29) in which the

piston (28) travels,

- a drive hub (27) comprising the discs (29), which is attached to the

primary shaft (55).

- The forward clutch is centred in the cover plate (38) of the reverse

clutch by the ball bearing (32).

Reverse clutch

The reverse clutch consists of:

- an epicyclic gear train consisting of three double planet gears (52)

and three single planet gears (59),

- a hydraulic braking device for the planet carrier (49),

- a cover plate (38) supporting the forward clutch and with an inner

face machined for fitting hydraulic components.

The double and single planet gears (52) (59) of the epicyclic gear train

mesh respectively on the input and output sun gears (53) (58). The pins

(50) are idle-mounted

and held in the planet carrier by plates (63).

A central drilled channel and radial ports supply lubrication to the

needle roller bearings (60). The planet carrier braking device consists

of an annular piston (39) and

a plate (43) that is loaded by springs (62) and discs (47) splined to

the planet carrier. The intermediate plates (46) are immobilised by the

pins (71).

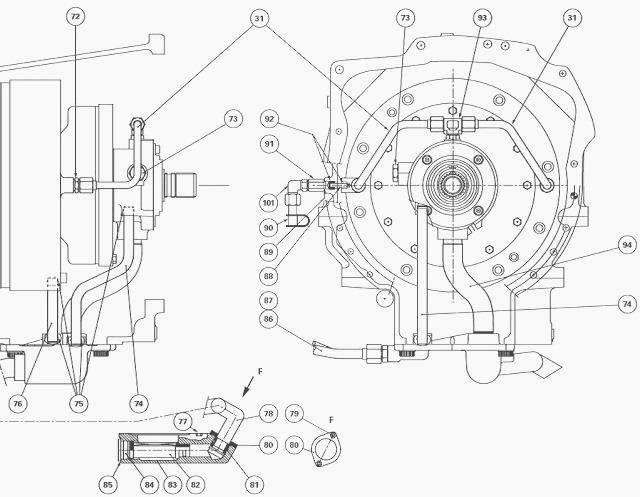

Fixed unit

The fixed unit (1) has two functions:

- it receives the low pressure supplying the forward clutch via the pipe

(74),

- it acts as a housing for the clutch lubrication and cooling pump.

The pipes (31) connecting the unit (1) and the cover plate (38)

lubricate the reverse clutch braking device. The shims (3) fitted

between the closing spacer (4) and

the fixed unit (1) provide axial clearance for the forward clutch.

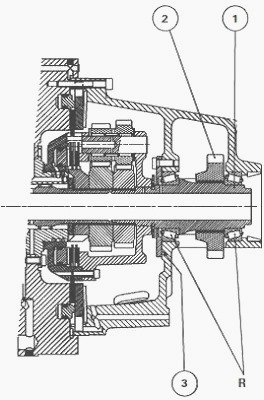

MF 5455, 5470 tractor drive transmission

Drive from the Power Shuttle is transmitted to a mechanical component

located in the rear compartment of the input box. This component

comprises a secondary

shaft (1) attached to the gear (2) by splines.

The shaft is fitted on

two tapered roller bearings "R", and is supported by two bearings of the

input unit. The shims (3)

fitted between the cover plate and the unit are used to preload the

bearings.

Forward clutch

When the lever under the Massey Ferguson 5455, 5470 steering wheel is in

the Forward position, the relevant solenoid valve is activated and

supplies a pressure

that moves the piston (28).

This, in turn, compresses the intermediate

plates (30) and the discs (29) against the bell (33).

The movement from the engine to the gearbox complies with the following

drive train:

- input shaft (19) splined to unit (18),

- unit (18);

- intermediate plates (30);

- discs (29) compressed by the piston (28);

- hub (27),

- primary shaft (55),

- main gearbox layshaft via the input gear.

Simultaneously, the pressure applied behind the piston (39) of the

braking device drops and the planet carrier assembly (discs (47),

intermediate plates (46) and

epicyclic gear train) rotate freely.

During forward operation, the oil flow from the centre housing via the

pump (14) is directed towards the intermediate plates (30) and the discs

(29) via the ports of

the forward clutch unit (18) opened by movement of the piston (28).

At

the same time, lubrication of the braking device of the planet carrier

(discs (47) and

intermediate plates (46)) of the reverse clutch is interrupted.

Reverse clutch

When the previously mentioned lever is moved from the Forward to Reverse

position, the solenoid valve concerned is activated and supplies the

piston (39) of the

braking device of the planet carrier.

The piston then presses on plate

(43) which compresses discs (47) and the intermediate plates (46)

against the front cover

plate of the input unit and stops the rotation of the planet carrier

assembly.

The drive from the engine is directly transmitted to the bell (33)

splined to the input sun gear (53), without passing through the discs

and intermediate plates of the

forward clutch. Simultaneously, the oil pressure in the chamber of the

piston (28) drops and frees the discs (29) and intermediate plates (30).

The input sun gear (53) then drives the double planet gears (52) freely

mounted on the pins (50) which, in turn, drive the single planet gears

(59) thus reversing the

rotation of the output sun gear (58) splined to the primary shaft (55).

The primary shaft then transmits the drive from the engine to the MF

5455, 5470 main gearbox layshaft via the input gear. A valve screwed to

the top section of the

cover plate (38) creates a small permanent bleed starting from 13 bar to

provide an automatic bleed of the piston supply system (39).

Lubrication

As the piston (39) moves, it operates spools (44) that act as valves and

compress springs (45) via the plate (43).

The spools have a drilled

centre channel and

radial ports, allowing oil to flow to the channels in the cover plate

(38) and the channels in the front cover plate of the input unit, thus

lubricating the discs (47) and the

intermediate plates (46).

Lubrication of the mechanical components of the epicyclic gear train is

via the lubricating system of the input unit. At the same time, the

lubricating oil flow to the

discs (29) and intermediate plates (30) of the forward clutch is

interrupted, thus preventing any possible drive to the discs due to a

"drag" effect.

Neutral position

In neutral position, the supply to the solenoid valves is cut, placing

the forward and reverse clutches at rest and eliminating transmission of

the engine drive to the

gearbox. The lubrication flow is also interrupted.

The pressure inside

the system opens the valve and directs the oil to the housing. After

changing a solenoid valve

or its coil, the Power Shuttle hydraulic unit, the unit or one of its

components or the electronic controller, it is necessary to calibrate

the clutches.

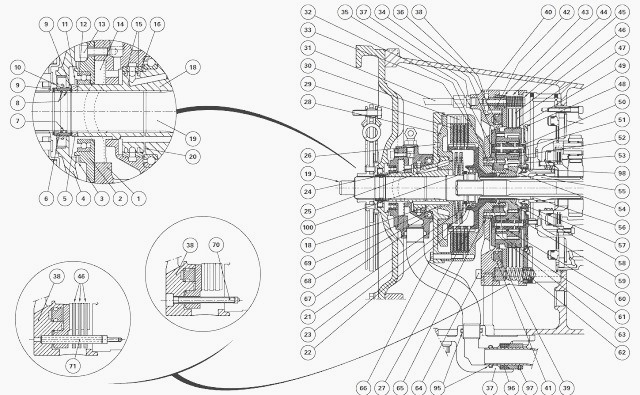

(1) Pump unit (2) Pump cover plate (3) Shim(s) (4) Spacer (5) Locking

ring (6) Splined ring (7) "O" ring (8) Anti-extrusion rings (9) Snap

rings (10) Seal (11) Circlip

(12) Ball bearing (13) Screw (14) Lubricating pump (15) Seal rings (16)

Ring (17) Centring pin (18) Forward clutch unit (19) Input shaft (20)

Pin (21) Circlip (22) Ball

bearing (23) Snap ring (24) Seal (25) Belleville washers (26) Index

holes (27) Drive hub (28) Forward clutch piston (29) Forward clutch

discs (30) Forward clutch

intermediate plates (31) Lubrication pipe (32) Ball bearing (33) Forward

clutch bell (34) Planet carrier cover plate (35) Rivets (36) Seal (37)

Cover plate (38) Reverse

clutch cover plate (39) Reverse clutch piston (40) Rivets (41) Seal (42)

Seal (43) Plate (44) Spools (45) Springs (46) Reverse clutch

intermediate plates (47)

Reverse clutch discs (48) Ring restrictor (49) Planet carrier (50)

Planet gear pins (51) Spacers (52) Double planet gears (53) Input sun

gear (54) Snap ring (55)

Primary shaft (56) Snap ring (57) Ball bearing (58) Output sun gear (59)

Single planet gears (60) Needle roller bearings (61) Snap rings (62)

Springs (63) Stop plates

(64) Screw (65) Snap ring (66) Screw (67) "O" ring (68) Ball bearing

(69) Seal (70) Screw (71) Pins (72) Union (73) 1.5 bar valve (74) Pipe

(75) "O" rings (76) Pipe

(77) Screw (78) Pipe (79) Screw (80) Flange (81) Seal (82) Strainer (83)

Cover plate (84) Plug (85) Seal (86) Pipe (87) Pipe (88) Transfer pipe

(89) Seal (Loctite)

(90) Diagnostics connector (lubrication) (91) Union (92) "O" rings (93)

Union (94) Pipe (95) "O" rings (96) Dust seal (97) Screw (98) Snap ring

(99) Screw (100) Ring

(101) Elbow union

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader