________________________________________________________________________________

MF 5410, 5450 mechanical reverse shuttle gearbox - Selector cover plate repair

Removing and install the cover Plate

Immobilise the Massey Ferguson 5410, 5450 tractor. Chock the left rear

wheel. Apply the hand brake. Chock between the frame and the front axle.

Drain the gearbox. Raise the rear right-hand side of the tractor with a suitable jack. Remove the wheel. Place an axle stand in position.

Remove the

right-hand step and any

surrounding parts that might hinder removal of the cover plate.

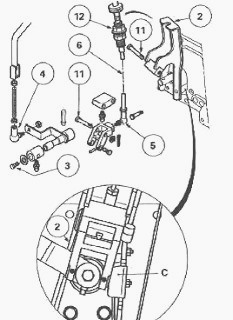

Removing the gear control

Disconnect the harness of sensor "C".

Remove the ball joint (4).

Remove the screw (3).

Remove the pins (11).

Disconnect the ball joint (5).

Mark the adjustment of the cable (6). Slightly loosen the top nut

(12). Separate the cable from the support (2).

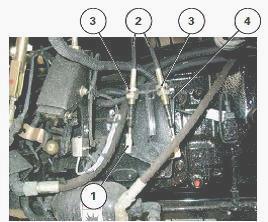

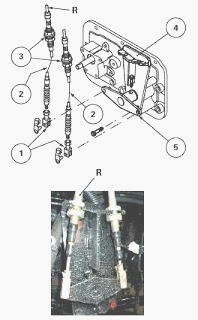

Removing the reverse shuttle control

Disconnect the clips (1). Mark the adjustment of the cables (2).

Loosen the lower nuts (3). Separate the cables from the support (4).

Disconnect the control cable (1) from the creeper or super creeper unit on MF 5410, 5450 tractors fitted with this option.

Remove the screws (3)

(4) and the nut (6),

marking the location of the earthing lug (2) and centring screws (4). If

fitted, remove the support (2) of the creeper or super creeper unit

control cable. Release and

remove the selector cover plate.

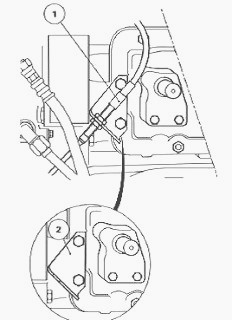

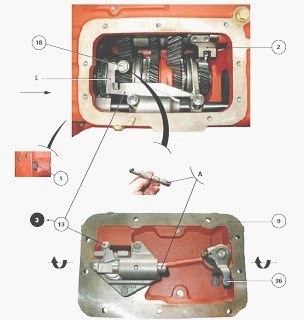

Clean the mating face of the gearbox and the cover plate. Install: the

3rd - 4th fork in ratio 3; the Hare / Tortoise range fork in Hare

position. Before refitting the cover

plate, check that the screw (1) is present.

Lightly smear the mating face of the gearbox housing with a sealing

product such as Loctite 510 or equivalent. Turn the finger (13) to the

left. Install the indexing rod

A in Hare position. Move the selector (2) and finger (36) to neutral

position.

Install the cover plate on the Massey Ferguson 5410, 5450 gearbox,

ensuring that:

- the finger (13) is positioned correctly in the forks;

- the finger (36) is engaged in the selector (2).

Install the creeper or super creeper control cable support (if fitted).

Install the earthing lug (2). Install and tighten the screws (3) (4) and

the nut (6) to a torque of 50 -

70 Nm.

The centring screws (4) must be fitted as shown. Depending on the

option, reconnect and adjust the creeper or super creeper control.

Reconnect the

harness on the neutral position switch.

Reconnect:

- the gear control and sensor "C".

- the reverse shuttle control.

Using a grease gun, lubricate the joints of the gear control on the

selector cover plate.

A - Indexing rod for locking the Hare/Tortoise fork, L - Synchronisation

of the Hare/Tortoise mechanism in Hare range, (3) Engaged gear (e.g. 3rd

gear) (1) Screw

(9) Selector cover plate (13) Finger (18) Locking stop

Check the shifting of all gears and the reverse shuttle. If required,

adjust the controls. Check the operation of the MF 5410, 5450 mechanical

reverse shuttle

gearbox. As required, Install any components removed previously from

around the cover plate.

Install the wheel. Tighten the nuts to a torque of 400 - 450 Nm.

Top up the oil level in the housings. Check it using the gauge at the

rear of the centre housing.

Remove the chocks between the frame and the front axle. Release the hand

brake.

Check that the buzzer of the safety sensor vibrates correctly (ignition

on, hand brake on and gear engaged).

Start the engine. When on the road, check:

- shifting up and down of the gear ratios;

- operation of the Hare / Tortoise range with the pulse button located

on the lever;

- operation of the reverse shuttle in the forward and reverse positions.

Check the tightness of the selector cover plate mating face and of the

hydraulic unions.

Disassembling and reassembling the gear selector and reverse shuttle

mechanisms

Take off the cover plate. Secure it in a vice fitted with protective

jaws.

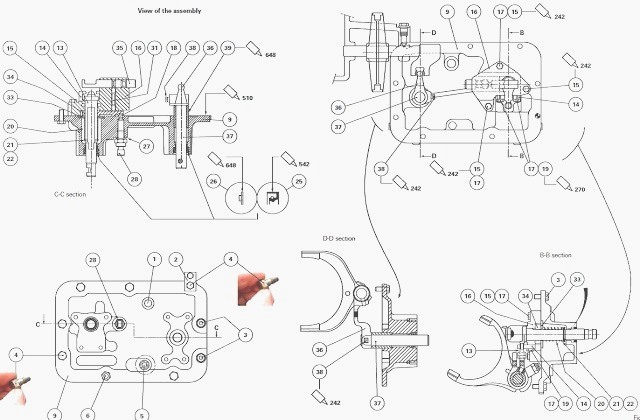

Gear selector mechanism

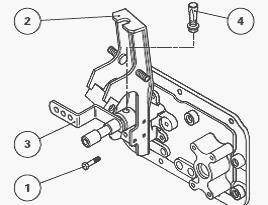

Remove the screws (1). Remove the key (4) and selector (3). Remove the

support (2) from the cover plate.

Remove the screws (15). Separate the cover plate (9) and support (16)

comprising the gear control assembly.

If necessary, extract the locating rings (17).

On the cover plate

Take off the Neutral position switch (28). Recover the seal (27) and

ball bearing (18).

Extract and discard the seal (25).

On the support

Take off the circlip (22), washer (21) and remove the spring (20).

Release the washer (33) and toggle switch (34), marking its position and

profile.

Recover the plunger (31). Extract the indexing rod (35).

If necessary:

- remove the screws (19);

- remove the speed grid (14);

- extract the locating rings (17).

Reverse shuttle selector mechanism

Take out the set screw (4). Remove the rod (5).

Remove the screws (1). Separate the support (2) from the cover plate

(9).

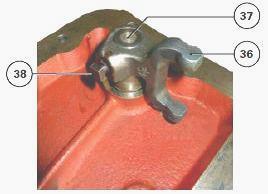

Take out the set screw (38). Remove the finger (36) and pin (37) from

the cover plate.

On the cover plate

Remove any plugs screwed to the cover plate.

Extract and discard the seal (25).

Gear selector mechanism

If it was necessary to replace the guide ring (26), lightly smear its

rim with Loctite 648 or equivalent. Install it up against the shoulder

of the cover plate.

On the support

If necessary:

- fit the locating rings (17),

- refit the speed grid (14) on the support (16),

- tighten the screws (19), lightly smeared with Loctite 270 or

equivalent, to a torque of 29 - 37 Nm.

Check that:

- the plunger (31) and indexing rod (35) move freely in the support

(16),

- the flat section of the toggle switch (34) slides normally on the

finger (13).

Slide the pin of the finger (13) into the support (16). Turn the toggle

switch (34) as required. Install it onto the finger (13). Fit the washer

(33). Install the spring (20)

and washer (21).

Install the circlip (22). Slide the plunger (31) into

its cavity in the support (16). Place the finger (13) in the Neutral

position. Turn the indexing rod (35)

as required and Install it.

On the cover plate

Check that the locating rings (17) are present. Install the gear control

and support (16) assembly on the cover plate (9).

Lightly smear the thread of the screws (15) with Loctite 242 or

equivalent. Tighten to a torque of 29-37 Nm.

Protect the lip of the seal (25) by surrounding the cylindrical end of

the finger (13) with a flexible protection.

Lightly smear the external rim of the seal with Loctite 542 or

equivalent and slide it onto the protection.

Remove the safety shield. Install the seal onto the cover plate using a

suitable fixture.

Check that finger (13) is in the Neutral position. Slide the ball

bearing (18) into the depression on the toggle switch (34).

Checking the Neutral position switch

Press manually on the button located at the end of the switch. Release

the pressure and check that the button returns freely to its initial

position.

Repeat the

operation several times. The check can be carried out using a

multimeter.

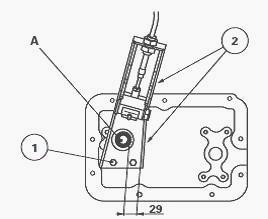

Install the switch complete with its seal and tighten to a torque of 15

- 25 Nm. Install the support (2), allowing a distance of 29 mm between

the support and the 22

mm diameter of pin A.

Lightly smear the screws (1) with Loctite 270 and

tighten them to a torque of 25 - 35 Nm. This dimension must be met for

the sensor to

operate correctly. Install the selector (3). Install and tighten the

key.

Checking the locking system of the indexing rod

In the grid (14), move the finger (13) from 1st to 4th ratio using the

selector (3) and manually check for the correct locking of the indexing

rod in each of its positions.

This indexing rod is linked to the Hare/Tortoise fork by an adjustable

stop. If the replacement of certain components of the locking system was

necessary, it is

mandatory to readjust this stop.

MF 5410, 5450 gearbox reverse shuttle selector mechanism

Assemble the finger (36) and pin (37). Lightly smear the thread of the

set screw (38) with Loctite 242 or equivalent.

Tighten this screw to a torque of 28 - 43 Nm.

If the guide rings (26) and (39) of the pin (37) needed replacing,

lightly smear the rim of each ring with Loctite 648 or equivalent.

Fit these rings up against their respective shoulders on the cover

plate. Install the support (2) on the cover plate (9).

Lightly smear the thread of the screws (1) with Loctite 270 or

equivalent. Tighten these screws to a torque of 25 - 35 Nm.

Slide the pin (37)/finger (36) assembly into the relevant bore on the

cover plate.

Protect the lip of the seal (25) by surrounding the cylindrical end of

the pin (37) with a flexible protection.

Lightly smear the external rim of the seal with Loctite 542 or

equivalent. Slide the seal onto the protection.

Remove the safety shield. Insert the seal into the cover plate using a

suitable fixture.

Install the rod (5). Lightly smear the thread of the set screw (4) with

Loctite 242 or equivalent.

Tighten this screw to a torque of 30-35 Nm. Remove the cover plate from

the vice. Refit it on the gearbox.

Assembling and adjusting the gear linkage and reverse shuttle control

cables

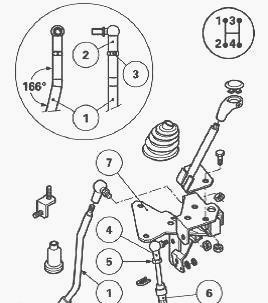

Gear linkage - cab side

On the end of the rod (1) shaped with an angle of 166°, position the

ball joint (2). Tighten the nut (3). Tighten the ball joint (4) up

against the cable (6). Tighten the nut

(5). Place the support (7) on a workbench.

On the support, fit and tighten:

- the transmission lever.

- the previously prepared rod and cable.

Install and secure the support onto the right-hand wheel housing of the

cab. During this operation, ensure the rod and cable are inserted

through the holes in the

compartments. Install the shield rings.

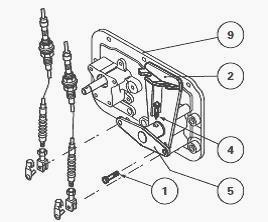

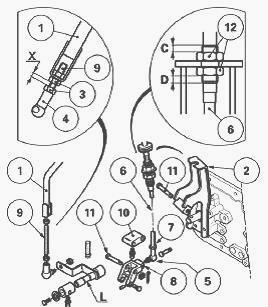

Gear linkage - selector cover plate side

Screw the threaded rod (9) (fitted with nuts (3) and the ball joint (4))

onto the rod (1).

Tighten the ball joint (5) up against the cable (6). Tighten the nut

(7).

Tighten and lock the other end of the ball joint (5) onto the cam (8).

On the previously fitted support (2) and lever "L", position the cam (8)

and its extension block (10).

Install the pins (11), and lock them in place with new pins. Install the

ball joint (4) on the lever L. Install the washer and tighten the

locknut.

Adjusting the rod (1) - Turn the threaded rod (9) and ball joint (4) to

obtain a dimension X of 17 ± 1 mm between the two nuts (3) when they are

tightened.

Adjusting the cable

Adjust the sheath end to balance (as far as possible) dimensions "C" and

"D". Tighten the nuts (12) without altering the adjustment.

Checking the proper engagement of each gear ratio and the position of

the lever in the opening of the console.

This check should be performed with the gaiter of the Massey Ferguson

5410, 5450 transmission lever temporarily removed.

Engage each gear ratio. During this operation, check that the lever is

never closer than 5 mm from the edge of the console.

Results

Lever movement is not hindered in any way by the console - Adjustment is

correct. Position the gaiter.

Lever movement is hindered by the console - The lever is positioned

incorrectly.

Readjust the rod (1) on the selector cover plate side in accordance with

the following instructions:

- If the problem concerns the 1st or 3rd gear, reduce dimension X.

- If the problem concerns the 2nd or 4th gear, increase dimension X.

- If the problem concerns lateral movement of the lever between the 1-2

and 3-4 gear paths (Neutral position), adjust the cable sheath end (6)

(dimensions C and D).

Tighten the nuts (12).

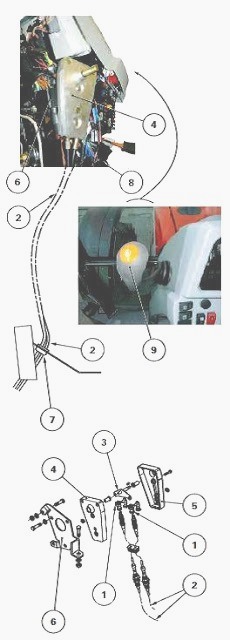

Reverse shuttle control cables - cab side

The assembled unit (4) and cables (2) are entered in the catalogue as a

complete assembly under a single reference. However, this assembly

comprises a number

of parts, most of which are available as spare parts.

Screw the clevises (1) level with the threaded end of the cables (2).

Install the clevises on the swinging lever (3).

Install the clips. Tighten the nuts. Slide the cable sheath ends into

the slots provided on the unit (4).

Position and tighten the cover plate

(5).

Assemble the support (6) on the unit (4). Attach the unit (4) / support

(6) assembly to the base of the instrument panel (8).

Ensure the cables are inserted into the hole in the cab floor. Position

the feed-through conduits (7).

Position the floor mat. Install the instrument panel cover and related

components.

Position the reverse shuttle lever. Tighten the screw after smearing it

with Loctite 242 or equivalent. Install the gaiter.

Reverse shuttle control cables – selector cover plate side

Screw the clevises (1) level with the threaded end of the cables (2).

Slide the sheath ends (3) into the slots provided on the support (4).

The cable fitted with an adhesive colour strip must be fitted in the

left-hand slot in the support (4). The adhesive strip can be stuck

anywhere on the cable and is

represented by the letter R.

If the adhesive strip is missing, position the cables in the slots so

that the shuttle lever position corresponds with the direction of

movement of the MF 5410, 5450

tractor:

- forward: lever pointing upwards

- reverse: lever pointing downwards

Place the rod (5) in neutral.

Install the clevises (1) to the rod. Tighten the clevis nuts.

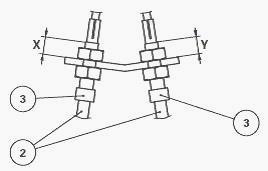

Cable adjustment

Gradually and alternately adjust the tension of the cables (2) using the

sheath ends (3) to achieve identical X and Y values, if possible.

Tighten the nuts without altering the adjustment.

Check

Alternately engage the forward and reverse positions.

For each ratio, check that the rod (5) locks correctly without excessive

cable tension.

Carry out a road test of the gear controls and reverse shuttle.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader