________________________________________________________________________________

MF 5430, 5450 mechanical reverse shuttle gearbox - Selector rail repair

Disassembly and reassembly operation

Creeper gear fork

Remove the rear right-hand wheel. Chock the Massey Ferguson 5430, 5450

tractor. Disconnect the creeper unit control cable on the rear axle.

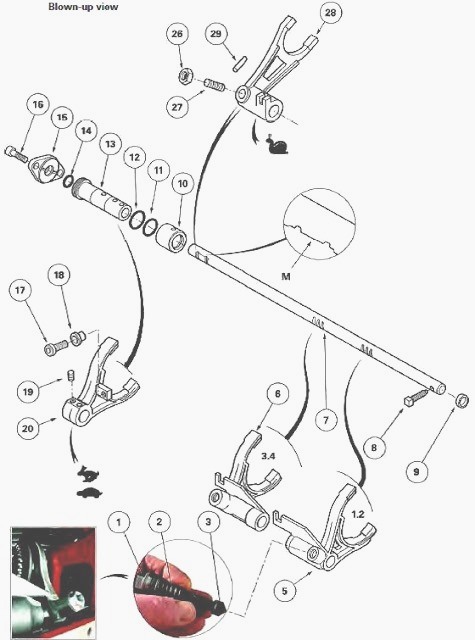

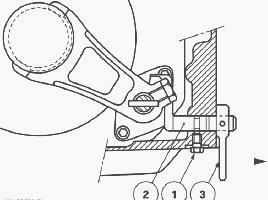

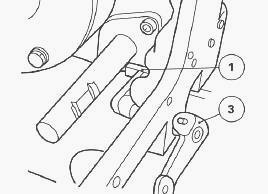

Remove the selector cover plate. Take out the plugs (1), the springs (2)

and the detent plungers (3) to release the selector rail.

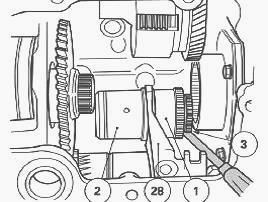

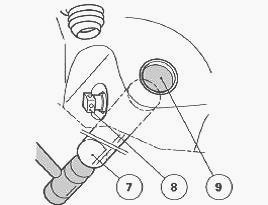

Remove the hydraulic cover plate(s). Remove the screw (1). Pull the rod

(2) and the lever (3) outwards to release the finger of the fork.

Unscrew the nut (26) and the locking screw (27) on the fork (28). Take

out the set screw (8).

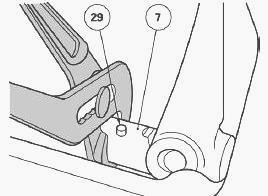

Turn the selector rail (7) and drive out the pin (29) without dropping

it into the housing. Move the selector rail forward.

Removing the pin (1) from the coupling sleeve (2) on a 2WD or 4WD Massey

Ferguson 5430, 5450 tractor.

Depending on the angular position of the coupling sleeve located between

the gearbox output shaft and the pinion, the pin is accessible or

inaccessible.

2WD tractor

If the pin (1) is accessible, drive it out from the sleeve.

If the pin (1) is not accessible:

- raise the tractor rear axle using a trolley jack;

- turn the pinion to correctly position the coupling sleeve;

- drive out the pin.

4WD tractor

If the pin (1) is accessible, drive it out from the sleeve.

If the pin (1) is not accessible:

- disconnect the front differential lock control hoses;

- remove the guard. Uncouple the rear sleeve from the transmission

shaft;

- turn the pinion to correctly position the coupling sleeve;

- drive out the pin.

Provisionally fit the set screw (8) in order to hold the selector rail

in place to remove the fork (28). Slide the sleeve (2) and the coupler

(1) closer together on the

connecting shaft (3). Note and mark the assembly order of the sleeve

(2).

Disengage the sleeve/connecting shaft/coupler assembly towards the outer

left-hand side. Take it out of the fork (28) and remove it through the

opening in the

right-hand cover plate. Remove the fork (28) on the selector rail (7).

Remove the lever (3).

To remove the creeper unit control rod (1), turn it so that it passes

beneath the selector rail (7). Discard the "O" ring (3). Clean and check

all components. Replace

those that are defective. Install the control rod and pull it as far to

the right as possible. Fit a new lubricated "O" ring. Install the lever

(3). Tighten the screw.

Install the fork on the selector rail. Ensure that the finger (1) of the

creeper gear control rod is pointing towards the front of the Massey

Ferguson 5430, 5450 tractor.

Couple the sleeve/connecting shaft/coupler assembly inside the housing.

Place it in the fork, turning the machined groove on the sleeve (2)

towards the rear of the tractor. Slide the sleeve and coupler onto the

connecting shaft. Install a

new double pin into the sleeve.

Take out the set screw (8). Install a

new pin (29) and turn the selector rail (7). Clean the set screw (8).

Smear its thread with Loctite

542 and tighten to a torque of 38 - 43 Nm.

Ensure that the ball bearing fitted at the end of the locking screw (27)

returns correctly to its initial position after pressure has been

applied manually by the locking

screw. Position the fork (28) and locking screw on flat section "M" of

the selector rail (7) (between the two locking slots.

Fully tighten the screw without forcing it in order to compress the ball

bearing. Loosen the screw by one-quarter turn. Clean the nut (26) and

smear with Loctite 270

or equivalent. Tighten to a torque of 15 - 20 while holding the locking

screw in place. Check that the fork locks correctly.

Turn and push the rod (2) in order to engage the finger in the fork. Fit

the screw (1) smeared with Loctite 542 or equivalent. Check that the rod

operates correctly.

Check that the "O" rings for the internal hydraulic pipes are not

damaged. Install the right-hand cover plate.

Attach the electrical harnesses with a retainer. Install the trailer

brake valve (if fitted, open centre), checking that the "O" rings are

not damaged. Tighten the screws

to a torque of 25-35 Nm. Reconnect the pipes and hoses via the hydraulic

cover plate. Install the strainer, support and filter (open centre).

If necessary, on 4WD MF 5430, 5450 tractors:

- couple the rear sleeve (5) of the transmission shaft (3);

- Install the guard (1);

- reconnect the front differential lock control hoses.

Install the plugs (1), the springs (2) and the detent plungers (3).

Install the selector cover plate. Reconnect and adjust the creeper unit

control cable.

Install the wheel. Remove the axle stand and the jack. Tighten the wheel

nuts to a torque of 400 - 450 Nm.

Top up the oil level in the rear axle and gearbox. Start the tractor.

Check the correct operation of the electrical and electronic circuits.

Check the tightness of the

cover plate mating face and the hydraulic unions. Carry out a road test

of the creeper unit control and 1st, 2nd, 3rd, 4th gears of the

Hare/Tortoise ranges.

Hare / Tortoise fork and lock- 1st / 2nd - 3rd / 4th fork assembly and

selector rail

Remove the right-hand rear wheel. Chock the Massey Ferguson 5430, 5450

tractor.

Remove the selector cover plate. Remove the right-hand hydraulic cover

plate.

Remove the plugs (1), the springs (2) and the detent plungers (3). The

detent plungers are now longer.

This modification improves their guiding into the forks (5) and (6) and

also into the plugs (1).

To optimise operation, a decompression spring on the detent plunger

drives out the oil enclosed in the spring chamber (2).

This design allows the plunger to enter and exit the fork more smoothly,

thus improving gear shifting. Take out set screw (8).

Drive out the cup plug (9) forwards by striking the rear end of the

selector rail (7).

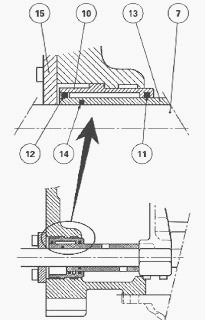

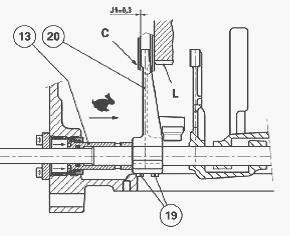

Place the Tortoise and Hare fork (20) in the Hare position. Remove the

adjustment screws (19).

Remove the screws (16) and the cover plate (15). Take out the Hare and

Tortoise piston (13) and discard the seals.

Remove the cylinder (10) and discard the seal. Turn the pump suction

pipe (1) upwards.

Move the selector rail (7) to the rear in order to release the forks.

Slide the selector rail under the rear axle housing reinforcement.

Take out the 1st-2nd and 3rd-4th gear forks. Extract the Hare and

Tortoise fork. If necessary, remove the locking stop (18).

Take the selector rail out through the selector cover plate opening by

passing it through the Hare / Tortoise cylinder bore.

Clean and check all components. Replace those that are defective.

Install the selector rail through the selector cover plate opening and

the Hare / Tortoise cylinder

bore.

Install the forks. Check that the hydraulic ports in the Hare /

Tortoise cylinder (10) are not obstructed. Install the cylinder fitted

with a new "O" ring (11).

The cylinder (10) is held in position:

- at the front, by the shoulder machined on its outer diameter;

- at the rear, by the cover plate (15).

Slide the selector rail forwards into the Hare / Tortoise fork and the

3rd-4th and 1st-2nd forks.

On the piston (13), fit the "O" rings (12) (14), and then insert the

piston into the cylinder bore (10) and onto the selector rail (7).

Turn the adjustment screw holes towards the tapped holes on the fork.

Temporarily lock the piston with a screw (19).

Install the cover plate (15) with the screws (16). Tighten the screws to

a torque of 25-35 Nm.

Clean the set screw (8). Smear its thread with Loctite 542 or

equivalent. Tighten to a torque of 38 - 43 Nm.

Smear the cup plug (9) with Loctite 542 or equivalent. Install it flush

with the housing.

Install the detent plungers, springs and locking plugs. Tighten the

plugs to a torque of 50 - 70 Nm.

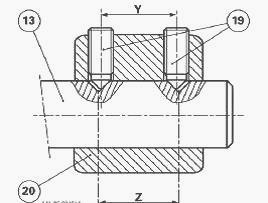

Adjusting the clearance between the Hare / Tortoise fork pads and the

synchroniser sliding coupler

The positioning of fork (20) is obtained by adjusting the difference in

the dimension between the centre line of the tapped holes "Y" and the

centre line of the indents

"Z" on the piston (13). A different fork movement is obtained either by

adjusting the front screw or by adjusting the rear screw according to

the adjustment required.

Position the control piston (13) and the sliding coupler "C" in the high

range (Hare).

Hold the sliding coupler manually against gear "L" of the high range.

Adjust the position of the fork (20) using the two adjustment screws

(19) previously cleaned in solvent and lightly smeared with Loctite 221

or equivalent, in order to

obtain a clearance of J1 = 0.3 mm between the rear face of the pad and

the sliding coupler.

For this adjustment, use the makeshift tool.

Position the control piston

(13) and the sliding coupler "C" in the low range (Tortoise).

Check that there is a clearance of J2 = 0.3 minimum (this value is

determined by the clearance J1) between the pad and the sliding coupler

when the latter rests

against the gear "T" of the low range.

Alternatively and progressively tighten the screws (19) to a torque of

25 - 35 Nm taking care not to modify the adjustment. In the Tortoise

position, if face "X" of the

fork pad (20) is driven against the sliding coupler "C", increase the

clearance J1. Check that the fork operates correctly.

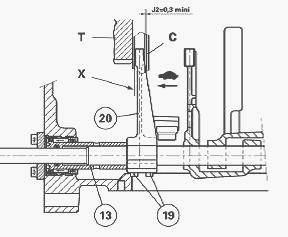

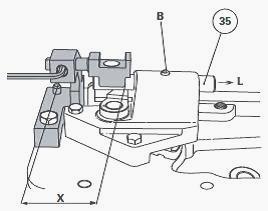

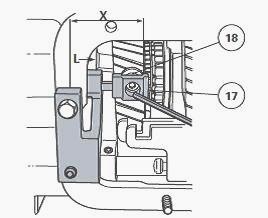

Adjusting the Hare / Tortoise fork locking stop

Locking is adjusted by an adjustable stop (18) located on the Hare /

Tortoise fork. This adjustment is obtained using a tool whose role

consists of conveying to the

locking stop the positioning of the indexing rod, mounted on the

selector cover plate.

The aim of this adjustment is to make the Hare/Tortoise mechanism safe

during operation, by mechanically locking the fork in the Hare or

Tortoise position. Before

adjusting the locking stop (18), it is essential to adjust the clearance

between the Hare/Tortoise fork pads and the synchroniser sliding

coupler.

On the cover plate

L - Mechanism synchronisation in Hare range, X - Tool dimension measured

on the selector cover plate and set on the gearbox, (3) Gear engaged

(e.g. 3rd gear),

(18) Locking stop, (31) Plunger, (35) Indexing rod

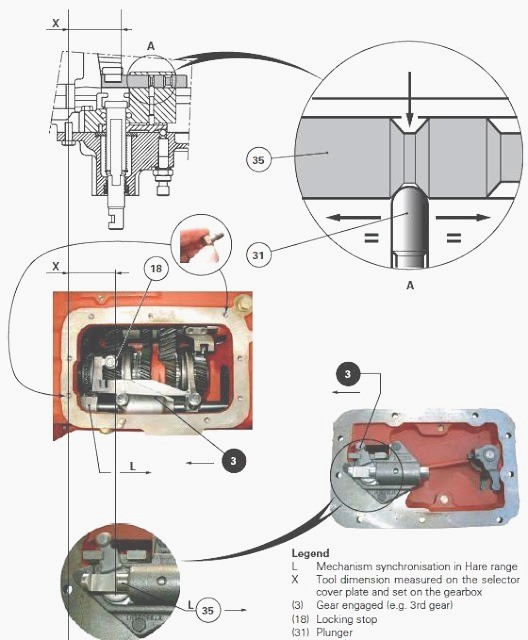

Place the indexing rod (35) in the high range position (Hare). Engage

the 3rd gear ratio. Install the tool on the selector cover plate. It is

essential to equally distribute

the clearance between the indexing rod and the plunger (31) (detail A).

Using the tool, measure dimension X according to pics.

On the MF 5430, 5450 gearbox

Engage the 3rd ratio. Using the tool, set dimension X on the gearbox.

Apply manual pressure on the fork towards the Hare range. Adjust the

locking stop (18) by

placing it in contact with the tool. Lightly smear the thread of the

screw (17) with Loctite 242 or equivalent. Tighten to a torque of 40-50

Nm.

Check

Check the operation of the Hare and Tortoise ranges. Check the smooth

operation of all gears.

Install the right-hand hydraulic cover plate. Install the selector cover

plate.

Reconnect and adjust the creeper unit control (if fitted). Install the

rear wheel.

Tighten the nuts to a torque of 400 - 450 Nm.

Top up the oil level in the housings. Check it using the gauge at the

rear of the centre housing.

Carry out a road test:

- of gears from 1st to 4th and vice versa;

- of the Hare and Tortoise ranges;

- of the creeper unit (if fitted).

Check the tightness of the cover plate mating faces and the hydraulic

unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader