________________________________________________________________________________

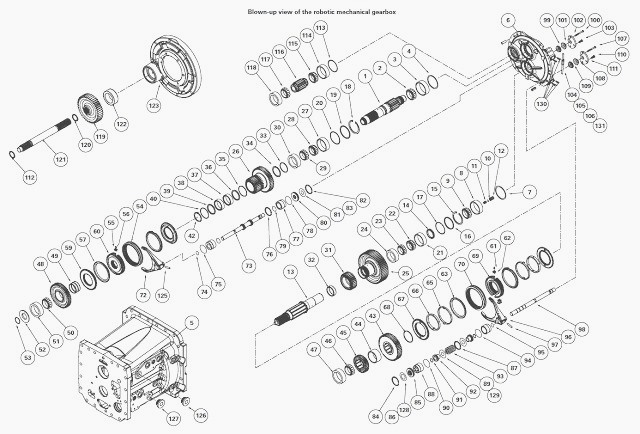

MF 5460, 5470 Robotic mechanical gearbox - Primary and secondary shafts

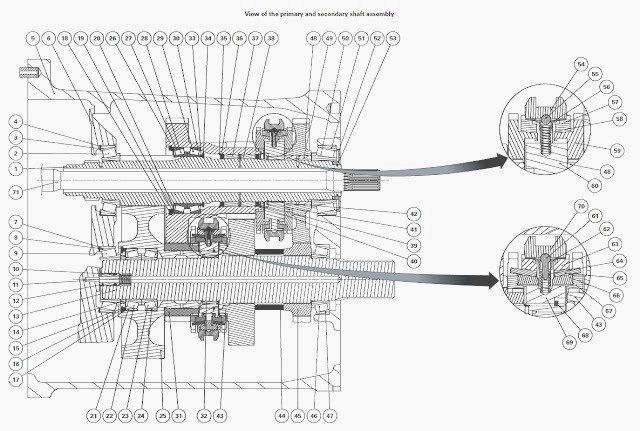

Disassembling the primary shaft

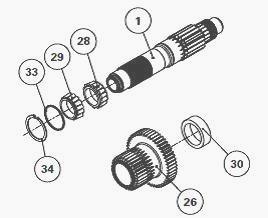

The bearing cones (2) and (50) are fitted tight on the shaft.

Position the shaft on a work surface with a suitable supporting fixture

to hold the shaft in a vertical position.

Take off the ring (53) at the end of the shaft (Massey Ferguson 5460,

5470 rear axle end).

Install a shouldered washer at the end of the shaft (1) in order to

Install an extractor.

Using the extractor, pull the pinion (48) and remove the bearing (50)

and the pinion (48). Recover the lubricating bush (49).

Remove the synchroniser assembly (60). Remove the circlip (42).

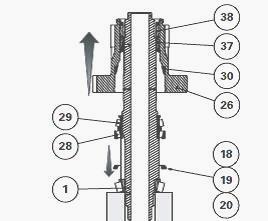

Take off the circlip (18) to remove the double pinion (26). The bearings

(37) and (38) stay in the double pinion (26).

The bearing cones (28) and (29) stay on the shaft (1). Recover the

washer (19) and the shims (20).

Remove the bearing cup (30) from the pinion (26). Check whether or not

there is a shim behind the cup.

Remove the snap ring (40). Take off the needle bearings (38) and (37)

with the spacers (36) and (39). Remove the snap ring (35) if required.

Remove the circlip (34), washer (33) and bearing cones (28) and (29). If

necessary, remove the bearing cone (2).

Reassembling the primary shaft

Pair up the cones (28)(29) and cups (27)(30). Install the bearing cones

(28) and (29) on the shaft (1).

Next install the washer (33) and circlip (34). It is assembled as an X.

The cones are placed back to back.

Install the cup (30) in the double

pinion (26). Check the

presence of the snap ring (35) in the double pinion.

Install the spacer (36), greased needle bearings (37) and (38), and

spacer (39) in the pinion (26). Install the snap ring (40).

Slide the shaft (1) into the pinion (26). Install the washer (19) and

circlip (18). Do not insert shims to measure the clearance during this

operation.

Shimming the pinion

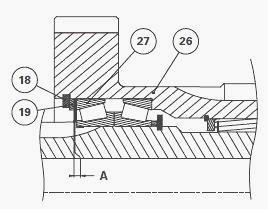

In order to position the bearings correctly, push and pull the pinion

(26) while turning it.

Place a dial gauge feeler pin on the surface of the pinion (26). Measure

the clearance A at three points.

Calculate the average of the three readings. Remove the circlip (18) and

the washer (19).

Between the cup (27) and washer (19) insert the thickness of shims

required to obtain clearance A: A = -0.05 to 0.05 mm.

Shim to the maximum tolerance (low preload).

Shimming the synchroniser overlap

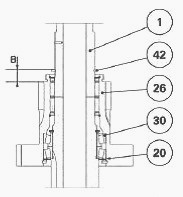

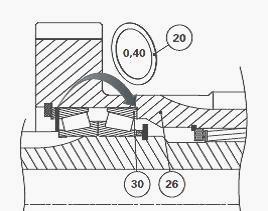

Install the thickness of shims. Install the circlip (42) holding the

synchroniser in position (60).

Using a depth gauge, measure distance B between the mating face of the

synchroniser (60) on the circlip (42) and the mating face of the pinion

(26).

Ensure distance B does not exceed 16.33 mm:

- If B<16.33: the dimensions are correct.

- If B>16.33: take out one 0.40 mm shim (20) used to shim the pinion

(26), and place it between the pinion (26) and the cup (30).

There are no intermediate shim sizes; use either the 0.40 mm shim or no

shim.

Once the shimming is complete, refit the synchronizer (60).

Make a paint mark to correctly align the lubricating ports on the

synchroniser hub and the shaft (1).

Reinstall the bush (49) and pinion

(48). Using a makeshift tool, fit

the bearing cones (2) and (50) on the shaft (1).

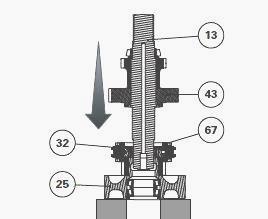

Disassembling the secondary shaft

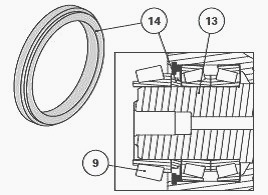

Take care not to pull the pinion (25) or the synchroniser will come

apart. The bearing cone (9) is freely mounted on the shaft (1).

Remove the bearing cone (9) and the spacer (14). Install the shaft

vertically on the pinion (25).

Pull the shaft (13) upwards with the pinions (43) and (45), taking care

not to disassemble the synchronizer (69).

Recover the needle bearing (32). Extract the snap ring (68). Remove the

synchronizer (69) and pinion (31). Turn over the pinion (25).

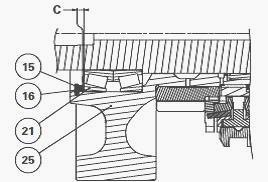

Take off the circlip (15), washer (16) and shims (17). Remove and pair

up the bearings (21)(22) and (23)(24).

Using an extractor, pull the pinion (45) and remove the bearing (46).

Remove the spacer (44) and pinion (43).

Reassembling the secondary shaft

On the shaft (13), Install: pinion (43), spacer (44), pinion (45).

Install the bearing cone (46) using a makeshift tool.

In the pinion (25), fit the roller bearings (21)(22) and (23)(24).

Install the washer (16) then the circlip (15). Do not fit shims (17).

Using a set of shims, measure the clearance C between the circlip (15)

and the washer (16).

Between the bearing (21) and washer (16) insert the thickness of shims

(17) required to obtain clearance C: C = -0.05 to 0.05 mm.

Shim to the maximum tolerance (low preload).

On the pinion (25), reinstall the pinion (31), its inner surface lightly

greased.

Reassemble the synchroniser (69) on the splines of the pinion (25).

Make a paint mark to correctly align the lubricating ports on the

synchroniser hub and the pinion (25).

Install the snap ring (68). Install the pre-greased bearing (32).

Position the pinion (25) on a support, with the synchroniser turned

upwards.

Thread on the shaft (13) assembled during, paying special attention when

inserting it through the needle bearing (32).

Install the spacer (14) and bearing cone (9) on the shaft (13). Ensure

the spacer shoulder is positioned the right way.

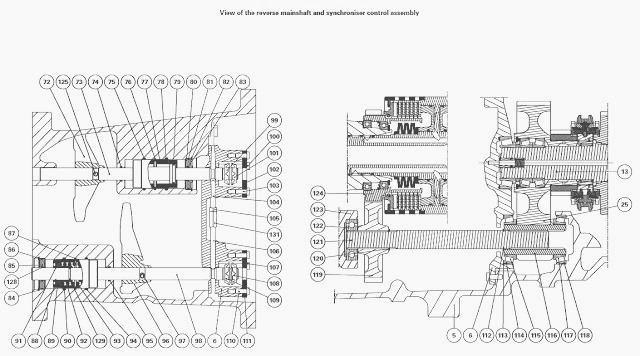

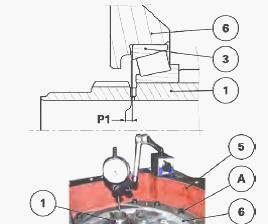

Shimming the primary shaft and reverse transfer pinion

Check the presence of the bearing cups (51), (47) and (118) in the

Massey Ferguson 5460, 5470 gearbox housing (5).

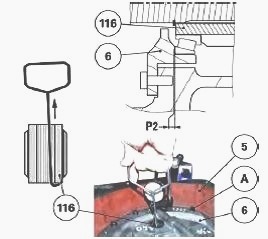

In the gearbox housing (5), position the primary shaft (1) assembled

during operations.

At the same time, Install the reverse transfer pinion

(116).

In the cover (6), Install the bearing cups (3) and (114) (assembled

without shims) with grease to keep them in the cover (6).

Reinstall the cover (6) on the housing (5). Install and tighten the cover screws (A). Place a dial gauge feeler pin at the end of the primary shaft (1).

In order to correctly seat the bearings, pull and push hard on the shaft

while turning it. To pull the shaft, use a lever positioned underneath

the gearbox.

Measure the clearance with a dial gauge. Calculate the thickness of

shims required to obtain preload P1: P1 = 0.05 to 0.10 mm.

Example if the clearance measured is 0.73: 0.73 + 0.05 = 0.78/ 0.73 +

0.10 = 0.83.

The thickness of shims required will be between 0.78 and 0.83. Get as

close as possible to 0.83.

Place the dial gauge feeler pin on the reverse transfer pinion.

Using a makeshift bent rod, pull the pinion to correctly seat the

bearings.

Measure the clearance with a dial gauge. Calculate the thickness of

shims required to obtain preload P2: P2 = 0.05 to 0.10 mm.

Remove the screws (A) and the cover (6). Take out the primary shaft and

reverse transfer pinion.

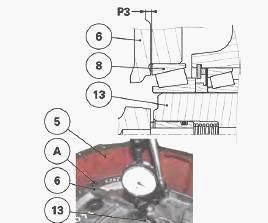

Shimming the secondary shaft

Check the presence of the bearing cup (47) in the MF 5460, 5470 gearbox

housing (5).

In the gearbox housing (5), position the secondary shaft (13) assembled

during operations.

In the cover (6), Install the bearing cups (8) (assembled without shims)

with grease to keep them in the cover (6).

Reinstall the cover (6) on the housing (5). Install and tighten the

cover screws (A).

Place a dial gauge feeler pin at the end of the secondary shaft (13).

In order to correctly seat the bearings, pull and push hard on the shaft

while turning it.

To pull the shaft, use a lever positioned underneath the gearbox.

Measure the clearance with a dial gauge. Calculate the thickness of

shims required to obtain preload P3: P3 = 0.05 to 0.15 mm.

If possible, shim to obtain maximum tolerance. Reinstall the shafts in the housing and fit the cover with the calculated shim thicknesses.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader