________________________________________________________________________________

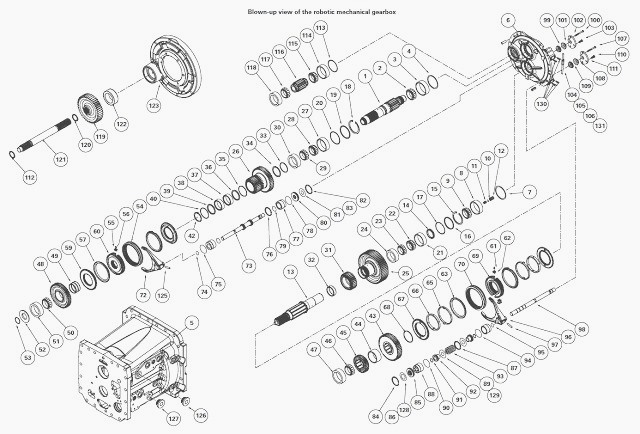

Massey Ferguson 5465, 5475 robotic mechanical gearbox - Selector rails and forks

To carry out this adjustment, the primary and secondary shafts must be

correctly supported and shimmed in the housing.

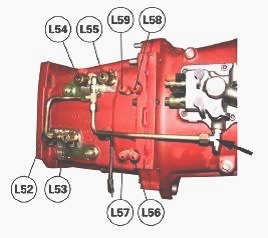

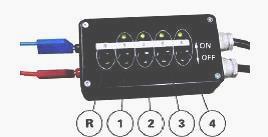

(L52) Range 1 control solenoid valve, (L53) Range 2 control solenoid

valve, (L54) Range 3 control solenoid valve, (L55) Range 4 control

solenoid valve, (L56) Range 1 switch, (L57) Range 2 switch, (L58) Range

3 switch, (L59) Range 4 switch

Install solenoid valves (L52), (L53), (L54) and (L55). Fashion a union

to supply the control circuit with compressed air at a maximum pressure

of 4 bar. Connect the selector rail adjustment tool.

The selector rail adjustment tool is used to supply the solenoid valves

(L52), (L53), (L54) and (L55) of the gearbox, in order to carry out

various adjustments.

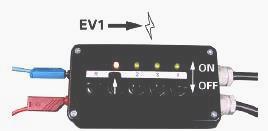

The range switches (L56), (L57), (L58) and (L59) can be checked once the

selector rails have been adjusted and the switches fitted. Each LED on

the tool corresponds to a switch.

The switches on the tool supply the solenoid valves of the Massey

Ferguson 5465, 5475 tractor gearbox. They work independently of the LED

lighting. The range switches light the LEDs of the tool. When a range is

engaged, the corresponding LED for the range is lit.

The switches are normally closed. When a range is engaged, they open the

circuit and the implement reverses the signal to light the LEDs. When

the switches are not connected, the four LEDs on the tool are thus lit.

Connect the tool to a 12V, 4A power supply.

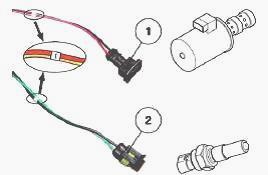

Connect the connectors (1) to the solenoid valves and the connectors (2)

to the range switches.

Each wire is marked with a number indicating the range concerned.

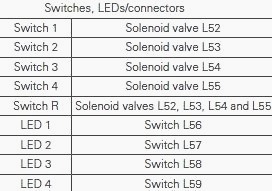

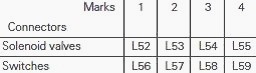

Switches, LEDs/connectors

Switch 1 - Solenoid valve L52, Switch 2 - Solenoid valve L53, Switch 3 -

Solenoid valve L54, Switch 4 - Solenoid valve L55, Switch R - Solenoid

valves L52, L53, L54 and L55, LED 1 - Switch L56, LED 2 - Switch L57,

LED 3 - Switch L58, LED 4 - Switch L59

Supplying the MF 5465, 5475 tractor gearbox solenoid valves Activate

switches 1, 2, 3 and 4 one by one, in order to supply the solenoid

valves required to adjust the selector rails. To return the two selector

rails to neutral automatically, use switch R on the implement (4

solenoid valves supplied).

Checking the selector rails before

adjustment

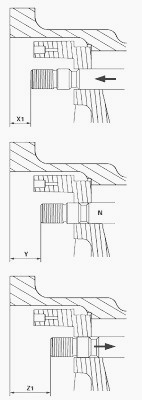

Before adjusting the travel of the selector rails, it is important to

check that their movement is within the permitted tolerances.

Using a depth gauge and a suitable fixture, check the following

dimensions (see the table):

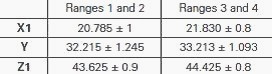

- X1: distance between face F of the housing and the end of the selector

rail with the range 1 or 3 engaged,

- Y : distance between face F of the housing and the end of the selector

rail in neutral position,

- Z1: distance between face F of the housing and the end of the selector

rail with the range 2 or 4 engaged.

X1 20.785 ± 1 21.830 ± 0.8

Y 32.215 ± 1.245 33.213 ± 1.093

Z1 43.625 ± 0.9 44.425 ± 0.8

If the measured dimensions are outside these tolerances, manually turn

the gears using the reverse driving pinion, then repeat the

measurements. If the dimensions

are still incorrect, check that the selector rails and synchronisers

have been fitted correctly.

Adjusting the selector rails

Set the rail (98) to neutral. Install the castellated nut without

tightening (109).

Engage range 2. (Supply L53). Tighten the nut (109) up against the cover

(6). Reposition the selector rail to neutral.

Screw on the nut (109) by two slots and line up the next slot opposite

the hole of the locking screw (107).

With paint, mark the position of the nut (109) in relation to the cover

(6).

The synchroniser may not fully engage when the MF 5465, 5475 gearbox is

not running.

If this is the case, position the shaft (121) and reverse transfer

pinion (119) and slowly run the gearbox while engaging the range.

Install the castellated nut (108). Screw it on until it is almost

touching the nut (109).

Ensure the nut (109) stays in its set position and that the paint marks

are not removed.

Install the plate (111). Install the screws (110) smeared with Loctite

242 or equivalent. Tighten to a torque of 29 - 37 Nm.

Engage range 1. (Supply L52). Unscrew the nut (108) fitted home against

the cover (111).

Reposition the selector rail to neutral.

Unscrew the nut (108) by two

slots and line up the next slot opposite the hole of the locking screw

(107).

With paint, mark the nut (108) aligned with the mark on the cover (6).

Insert the screw (107) to lock the nuts (108) and (109), aligning the

marks made during operations.

Check for correct operation. The nuts should effectively act as a stop.

Firmly fit the screw (107), lightly smeared with Loctite 242 or

equivalent. Tighten to a torque of 12 - 16 Nm.

Adjusting selector rail (73) (ranges 3 and 4). Repeat operations with

the selector rail (73) and nuts (99) and (101).

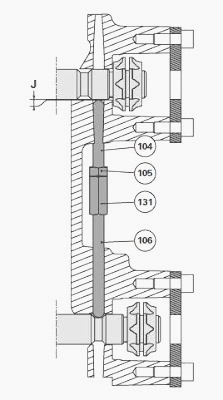

Adjusting the interlock mechanism

This adjustment must be carried out after setting the MF 5465, 5475

tractor gearbox selector rails.

Screw home the rod (106) in the reverse pitch nut (131).

Using the selector rail adjustment tool, engage a range on a selector

rail and leave the other selector rail in neutral.

Unscrew the rod (104) until the lock reaches maximum axial clearance as

shown in: J = 0.1 to 0.3 mm. Tighten the locknut (105).

Check - Using the selector rail adjustment tool, engage a range on a

selector rail. Try to shift a range on the other selector rail. It

should not engage. Repeat the

procedure with all the ranges.

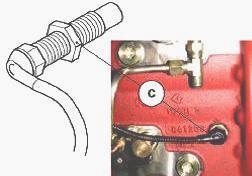

Assembling the intermediate speed sensor

Install the sensor (C) lightly smeared with Loctite 577 or equivalent.

Screw the sensor home on the pinion (25) without forcing it, then

unscrew of a turn. Tighten the locknut to a torque of 5 - 7 Nm.

Install the gearbox on the rear axle and engine. Reconnect the harnesses

and hydraulic pipes that were removed.

Check the level of the transmission oil. Carry out a gearbox calibration and check the transmission for correct operation.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader