________________________________________________________________________________

Massey Ferguson 5610, 5612 Dyna 6 Transmission - Power Shuttle

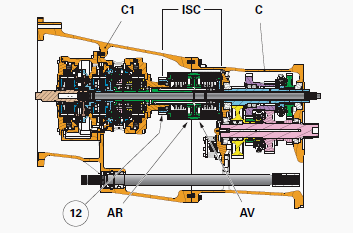

The Power Shuttle is fitted to Massey Ferguson 5610, 5612 tractors equipped with a GBA15 robotic mechanical gearbox.

It is located between front housing C1 of the Powershift module and

housing C of the robotic gearbox. It acts as the main clutch for the

Dyna-6 transmission.

The MF 5610, 5612 Power Shuttle Dyna 6 comprises two

electrohydraulically controlled multidisc clutches: the front multidisc

clutch for forward travel / the rear multidisc clutch for reverse

travel.

This comprises:

- a bell housing;

- a hydraulic piston fitted with Quadring seals;

- a set of ten Belleville washers;

- a hub splined to the primary shaft of the robotic gearbox;

- a set of nine discs and nine intermediate plates;

- a cover plate.

It comprises the same hydraulic and mechanical components as the front

clutch with the exception that, for the rear clutch, the hub forms a

unit with the reverse

driving gear (12). The Power Shuttle multidisc clutches are fitted back

to back. Their clutch bell housing is driven by a common shaft.

The Massey Ferguson 5610, 5612 tractor multidisc clutches are supported:

- at the front by a support fixed to the rear of the Dynashift module;

- at the rear by the robotic gearbox primary shaft.

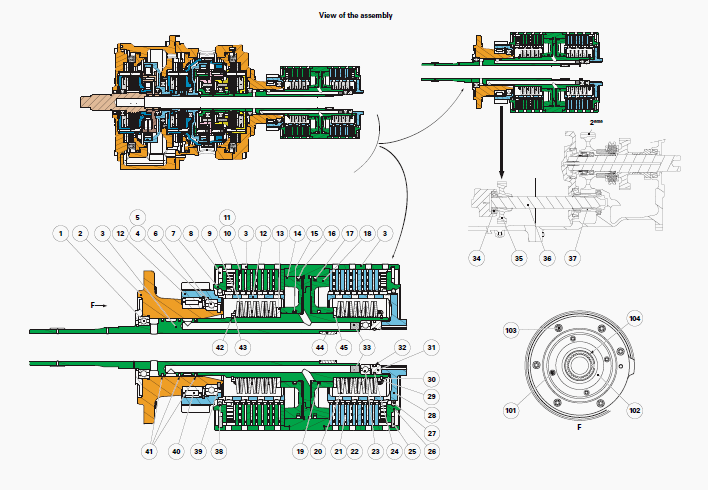

Parts list

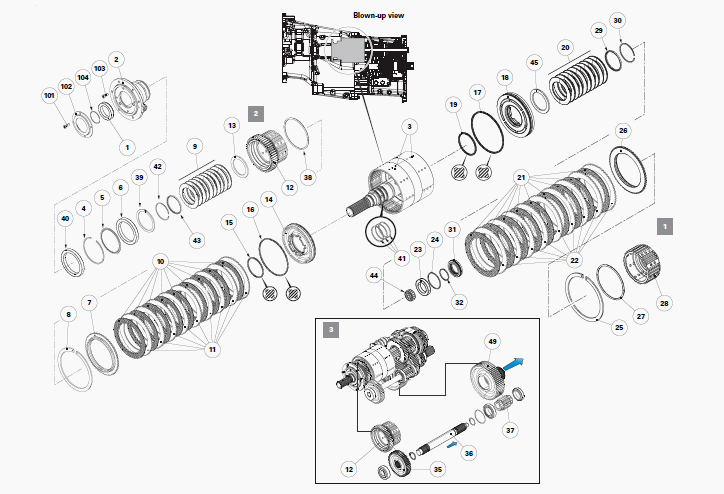

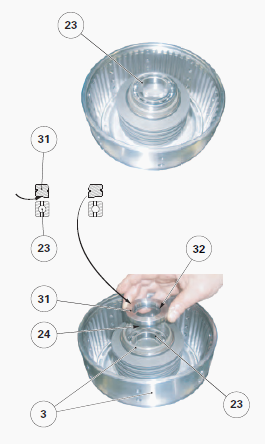

(1) Ball bearing sealed on one face, (2) Bearing carrier, (3) Shaft/bell

housings, (4) Circlip, (5) Thrust washer, (6) Ball bearing, (7) Cover

plate (reverse clutch), (8)

Circlip, (9) Belleville washers, (10) Discs (reverse clutch), (11)

Intermediate plates (reverse clutch), (12) Hub/reverse driving gear

unit, (13) Thrust washer, (14)

Piston (reverse clutch), (15) Quadring seal, (16) Quadring seal, (17)

Quadring seal, (18) Piston (forward clutch), (19) Quadring seal, (20)

Belleville washers, (21)

Discs (forward clutch), (22) Intermediate plates (forward clutch), (23)

Ball bearing, (24) Seal ring, (25) Circlip, (26) Cover plate (forward

clutch), (27) Snap ring, (28)

Hub (forward clutch), (29) Countersunk thrust washer, (30) Snap ring,

(31) Seal holder, (32) "O" ring, (33) Rivets, (34) Ball bearing, (35)

Reverse driven gear, (36)

Reverse layshaft, (37) Reverse layshaft gear, (38) Snap ring, (39)

Circlip, (40) Cylindrical roller bearing, (41) Seal rings, (42) Snap

ring, (43) Countersunk thrust

washer, (44) Needle roller bearing, (45) Thrust washer, (49) 2nd gear

(robotic mechanical gearbox), (101) M6 screw, (102) Thrust plate, (103)

M8 screw, (104)

Snap ring, 1 - Forward clutch, 2 - Reverse clutch, 3 - Reverse

kinematics

Removing and refitting the front support and the Power Shuttle multidisc

clutches

If the operation is limited solely to the removal of one or more of the

following parts of the forward clutch:

- discs (21);

- intermediate plates (22);

- hub (28);

- seal holder (31);

- ball bearing (23),

Simply disassemble the MF 5610, 5612 tractor between housing of the

robotic gearbox (C) and housing of the Powershift module (C1).

If it is necessary to completely remove the PowerShuttle, proceed as

follows:

- Disconnect the Massey Ferguson 5612, 5610 tractor between housing C of

the robotic gearbox and housing C1 of the Powershift module.

- Separate housing C1 from the engine. Remove the Powershift module.

- Open the Powershift module between the housing and the rear cover

plate of the Dynashift module.

- Remove clutch O/brake N from the Dynashift module.

- Place the Power Shuttle in a vertical position on a suitable support.

- Unscrew the M8 screws. Separate the Power Shuttle from the rear cover

plate of the Dynashift module.

Removing front support

Remove: the M6 screws (101); the thrust plate (102); the snap ring

(104).

Remove: the ball bearing (1) while making a note of the positioning of

its sealed face F; the circlip (8).

Separate front support from the Power Shuttle.

Front support mainly comprises the bearing carrier (2), the thrust

washer (5) (oil deflector), the bearings (6) (40) and the unit (12).

The unit (12) is an assembly composed of the clutch hub and the reverse

driving gear.

The cover plate (7) is clipped onto the unit (12) using the snap ring

(38). Remove the circlip (39).

Separate the bearing carrier (2) from the unit (12).

If necessary, extract the cylindrical roller bearing (40) from the

bearing carrier (2).

On the unit (12), remove: the circlip (4); the thrust washer (5); the

ball bearing (6).

Refitting front support

Clean and check all components. Replace those that are defective.Inside the unit (12), refit: the ball bearing (6); the thrust washer

(5). Its profile P must be facing the ball bearing (6); the circlip (4).

If removed, fit the cylindrical roller bearing (40) to the bearing

carrier (2). Check that the cylindrical roller bearings rotate freely.

Fit the bearing carrier (2) to the unit (12). Refit the circlip (39).

Refit front support S1 to the Power Shuttle. The junction between front

support S1 and the Power Shuttle can be made: either by using method M,

which consists of

placing front support S1 on a suitable support S drilled with a central

hole to allow the bell housing shaft (3) to descend towards the discs

(10) and the intermediate

plates (11); or by using method M1 which consists of placing the Power

Shuttle on a suitable support S to allow front support S1 to descend

towards the discs (10)

and the intermediate plates (11).

Refit: the ball bearing (1), positioning its sealed face F downwards;

the snap ring (104); the thrust plate (102); the M6 screws (101):

Lightly smear their threads with

Loctite 242 or equivalent beforehand.

Tighten to a torque of 16 Nm; the

rear cover plate (52) of the Dynashift module: Lightly smear the M8

screw (103) threads with

Loctite 242 or equivalent beforehand. Tighten to a torque of 37 Nm.

Removing the MF 5610, 5612 reverse multidisc clutch

Place the Power Shuttle in a vertical position on a suitable support S.

Remove: the thrust plate (102), the snap ring (104), the ball bearing

(1) and the circlip (8),

repeating steps; front support S1; the discs (10) and intermediate

plates (11); the seal rings (41) and then discard them.

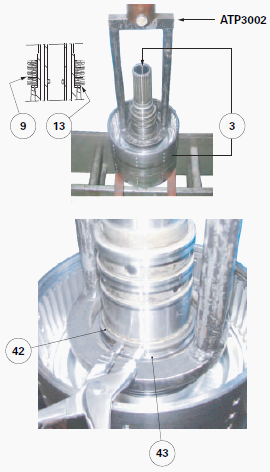

Place the bell housing shaft (3) on a table press with its splines

facing upwards.Using a hydraulic press and service tool ref. ATP3002, compress the ten

Belleville washers (9).

Remove: the snap ring (42); the countersunk thrust washer (43). De-compress the hydraulic press ram. Remove the tool. Make a note of the layout of the Belleville washers.

Remove them from

their clutch bell housing with the thrust washer (13).

Gently drive out the piston (14) using compressed air. Remove and

discard the Quadring seals (15) (16).

Disassembling the forward multidisc clutch

Turn over the Power Shuttle. Place it on a table press with the bell

housing shaft (3) facing downwards.

The principle for removing the discs, intermediate plates and Belleville

washers for the forward clutch is similar to the principle for removing

the reverse clutch.

Remove: the circlip (25); the cover plate (26) fitted with the snap ring

(27) and the hub (28); the discs (21) and intermediate plates (22).

Compress the Belleville washers (20) using a hydraulic press and the

service tool used for the reverse clutch.

Remove: the snap ring (30); the countersunk thrust washer (29).

De-compress the hydraulic press ram. Remove the tool.

Make a note of the layout of the Belleville washers. Remove them from

their clutch bell housing with the thrust washer (45).

Gently drive out the piston (18) using compressed air. Remove and

discard the Quadring seals (17) (19).

Remove: the seal holder (31). Discard the "O" ring (32) and the seal

ring (24); the ball bearing (23). If necessary, drive out the needle

roller bearing (44).

Reassembling the reverse multidisc clutch

Clean and check all components. Replace those that are defective.

On the bell housing shaft (3), clean mainly: the hydraulic channels of

the reverse (14) and forward (18) pistons; the radial lubricating holes.

Lubricate the new Quadring seals (15) (16) and the bore of the clutch

bell housing concerned. The Quadring seals are square seals.

Fit the seals into the grooves of the piston (14) without twisting them.

Position the piston in its clutch bell housing.

Gradually fit it in place, tapping alternately on its rim using a

plastic fitting drift.

On the bell housing shaft (3), slide and position; the thrust

washer (13); the ten Belleville washers (9) according to the layout

noted in step.

On the bell

housing shaft (3), position: the countersunk thrust washer

(43) against the set of Belleville washers; the snap ring (42) in the

recess of the countersunk

thrust washer.

De-compress the hydraulic press ram. Remove tools.

On the bell housing shaft (3), lightly smear grooves of the seal rings

(41) with miscible grease.

Fix a new seal ring inside the base of each groove, ensuring that it

does not exceed the circumference of the bell housing shaft.

Fit: the circlip (8); the ball bearing (1); the snap ring

(104); the thrust plate (102).

Lightly smear the thread of the M6 screws (101) with Loctite 242 or

equivalent. Tighten to a torque of 16 Nm.

Check that the unit (12) rotates freely (hub/reverse driving gear).

Refitting the MF 5612, 5610 forward multidisc clutch

Clean and check all components. Replace those that are defective.

Check that the rivets (33) are present on the rear end of the bell

housing shaft (3).

If removed, fit a new needle roller bearing (44) inside the bell housing

shaft (3) using a suitable fitting drift. Check that the needles rotate

freely.

Lubricate the Quadring seals (17) (19) and the bore of the clutch bell housing concerned. The Quadring seals are square seals. Fit the seals into the grooves of the piston (18) without twisting them. Position the piston in its clutch bell housing.

Gradually fit it in

place, tapping alternately on its rim using a plastic fitting drift.

On the bell housing shaft (3), slide and position: the thrust

washer (45); the ten Belleville washers (20) according to the layout

noted in step.

On the bell housing shaft (3), position: the countersunk thrust washer

(29) against the set of Belleville washers; the snap ring (30) in the

recess of the thrust washer.

De-compress the hydraulic press ram. Remove tools. Smear the "O" ring

(32) and the seal ring (24) with miscible grease. Position them in their

respective groove

on the seal holder (31).

Slide the complete ball bearing (23) and seal holder (31) into the bore

of the bell housing shaft (3). If the discs (21) are to be replaced,

soak the new discs in clean

transmission oil for approximately one hour.

Check that they are well impregnated with oil before fitting them. Start assembly by fitting an intermediate plate against the piston (18) and alternate until the new intermediate plates (22) and new discs (21) (new or re-used depending on the situation) are fitted.

The fitting should end

with a disc (new or re-used, depending on the situation) against the

cover plate (26).

Fit: the cover plate (26) fitted with the snap ring (27); the circlip

(25). Check that the clutch hub (28) rotates freely.

Place the Power Shuttle in a vertical position on a suitable support S.

Fit the rear cover plate (52) of the Dynashift module to the Power

Shuttle.

Lightly smear the thread of the M8 screws (103) with Loctite 242 or

equivalent. Tighten to a torque of 37 Nm.

Refit clutch O/brake N of the Dynashift module.

Close the Powershift module between the housing (111) and the rear cover

plate (52) of the Dynashift module.

Refit the Powershift module. Fit housing C1 to the engine. Reconnect the tractor between housing C of the robotic gearbox and housing C1 of the Powershift module. Calibrate the Power Shuttle. Carry out a road test on the Power Shuttle.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader