________________________________________________________________________________

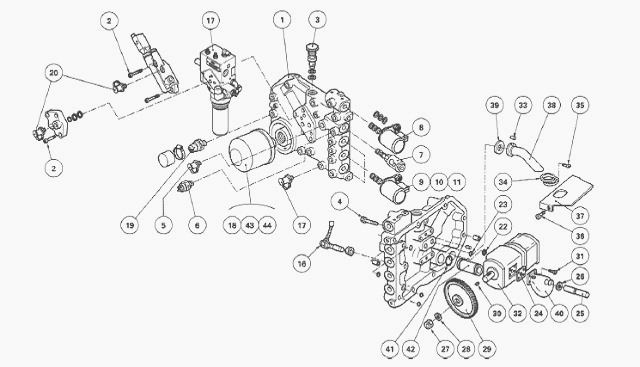

Massey Ferguson 6160, 6170 hydraulic circuit right-hand cover

Removing and install

Immobilise the Massey Ferguson 6160, 6170 tractor. Chock the left rear

wheel.

Put on the handbrake. Chock between the frame and the front axle.

Partially bleed the rear axle housing.

Take off the wheel concerned. Position an axle stand.

Removal

Disconnect the clogging indicator harness (12), and remove the 15 micron

filter (14) and its base.

Disconnect and block off the hydraulic unions supplying the spool

valves.

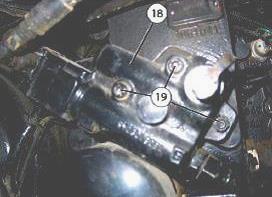

If the tractor is equipped with a trailer braking system, take out the

screw and (19) remove the valve (18).

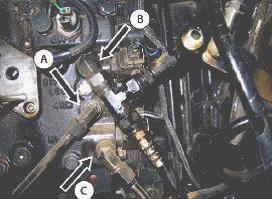

Disconnect and block off the hydraulic unions on the block (17).

Remove the block (17). Disconnect and block off the hydraulic unions (A)

(B) (C) on the right-hand cover.

Disconnect and block off the hydraulic union (D) on the MF 6160, 6170

hydraulic circuit right-hand cover.

Locate and disconnect the solenoid valve electrical connectors.

Remove the suction strainer (18). Disconnect and remove the filtration

switch (19).

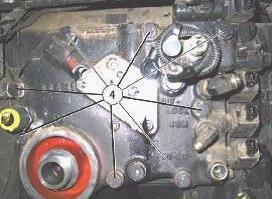

Loosen and remove the screws (4) securing the right-hand cover.

Install a guide stud (G1) to prevent the cover from falling. Release and

remove the housing cover.

Installing

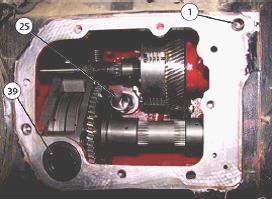

Clean the mating face of the housing and check the transfer pipe (25) is

in place. Install a new seal (39). Check the two locating pins (1) are

in place.

Clean the mating face of the right-hand cover, smear it with Loctite 510

or equivalent, and Install the new seals (39) (2) (3).

Install two guide pins (G1) to the housing, and Install the cover onto

(G1).

Place the cover on the housing and fit two diametrically opposing screws

(4).

Remove the guide pins (G1), and Install and tighten all screws (4) to a

torque of 72 - 96 Nm (Loctite 241). Connect the filtration switch (19)

connector.

Install the suction strainer (18) and the filtration switch protector.

Direct the discharge hole on the latter downwards.

Connect the electrical connectors on the solenoid valves according to

the marks made at disassembly. Connectthe hydraulic union (D).

Connect the hydraulic unions (A) (B) (C). Install the block (17).

Connect the hydraulic unions on the block (17).

If the MF 6160, 6170 tractor is equipped with a trailer braking system, Install the brake valve (18) and tighten the screws (19).

Connect the

hydraulic supply unions

of the hydraulic spool valves. Install the 15 micron filter (14) and its

base. Install the clogging indicator harness.

Reinstall the wheel, then tighten the nuts to the torque stated below.

Remove the axle stand, top up the oil level in the housing and check it

using the gauge located

to the rear of the centre housing.

Check the tightness of the mating faces and hydraulic unions. Wheel

tightening torque: 400-450 Nm

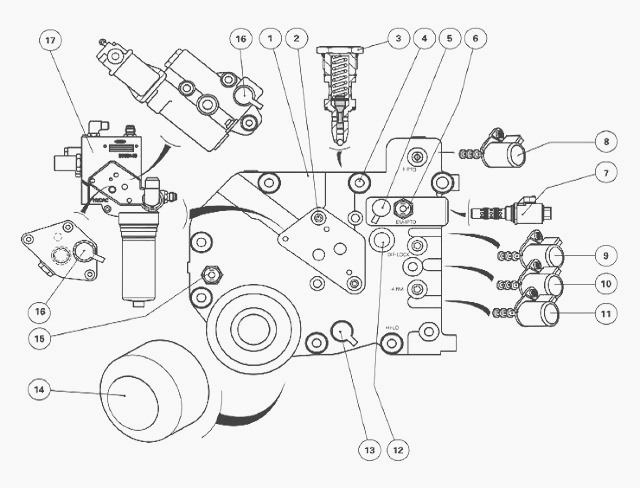

- The function of each solenoid valve is moulded on the outside face of

the hydraulic cover casting.

- The cover is fitted with three different types of solenoid valves.

- Out of the four or five solenoid valves fitted (depending on version),

the "Fluid Power System" solenoid valve (7) of the PTO clutch is of the

proportional type.

- The "Parker" solenoid valve (8) of the Massey Ferguson 6170, 6160 PTO

brake has a solenoid valve with a diode and is represented by the

following symbol.

- The body of the "Parker" solenoid valve (11) must be Installed to the

control circuit of the Hare / Tortoise mechanism. It features a machined

end-piece on one of

its ends. Take out the screws (4) and remove the cover.

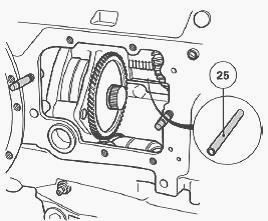

After removing the cover, if necessary remove from the housing the

transfer pipe (25), ensuring hydraulic continuity with the pump

manifold.

Installing

Clean the mating faces of the housing and the cover.

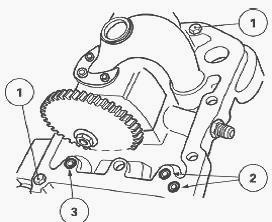

Check for the presence of the two locating pins (1) and rivets at the

ends of the channels on the cover. Install new seals:

- on the Hare / Tortoise channels (2)

- on the power take-off clutch channel (3).

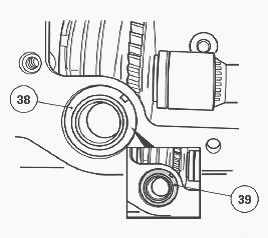

Install and position the suction pipe (38), with its notch along the

axis of the pin inserted in the housing. Put in place seal (39).

Screw two locally made guide pins into opposing holes on the housing.

Reinstall the transfer pipe if it was previously removed.

Smear the mating faces of the cover with a sealing product (Loctite 510

or equivalent) taking care not to block the hydraulic ports of the Hare

/ Tortoise mechanism.

Reinstall the cover. Take out the guide pins. Install and tighten the

screws (4) to a torque of 72 -96 Nm.

Reconnect (according to the markings made):

- solenoid valves

- filtration switch

- low pressure switch

- engine speed sensor.

Attach the electrical harnesses using a cable clip. Reconnect the pipes

and hose. Reinstall the valve (6) (if fitted).

Check the condition of the strainer seal (18) and lubricate it.

Reinstall the strainer and tighten it an additional quarter turn after

it contacts with the cover.

Reinstall the 15 micron filter and its base. Reconnect the filter

clogging indicator.

Lift the MF 6170, 6160 tractor. Reinstall the wheel. Remove the axle

stand and tighten the nuts to a torque of 400 - 450 Nm. Remove the

chocks.

Top up the transmission oil level of the rear axle and check it using

the gauge located to the rear of the centre housing.

Check the operation of the electrical circuits, the low pressure switch,

the solenoid valves, the filtration switch and the filter clogging

indicator.

If the pump has been replaced, or if the disassembly of one or several hydraulic component(s) was necessary, check the hydraulic circuit by carrying out the relevant tests. Check the tightness of the cover mating face, the strainer and the hydraulic unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader