________________________________________________________________________________

Massey Ferguson 6255, 6270, 6170, 6180 - hydraulic system tests

Massey Ferguson 6100-6200 series tractors open centre hydraulic system (57 l/min) comprises two systems: the low flow rate system and the high flow rate system.

Before starting the tests, run the engine at 2000 rpm to raise the oil temperature to 60 °C (132 °F) minimum.

To make the rise in temperature easier, connect a flowmeter to one of the auxiliary spool valves other than the one supplied by the flow divider (if fitted) and limit the flow through the flowmeter.

As soon as the oil temperature reaches or exceeds 60°C (132°F), release

the lever of the auxiliary spool valve and open the flowmeter load valve

to the maximum.

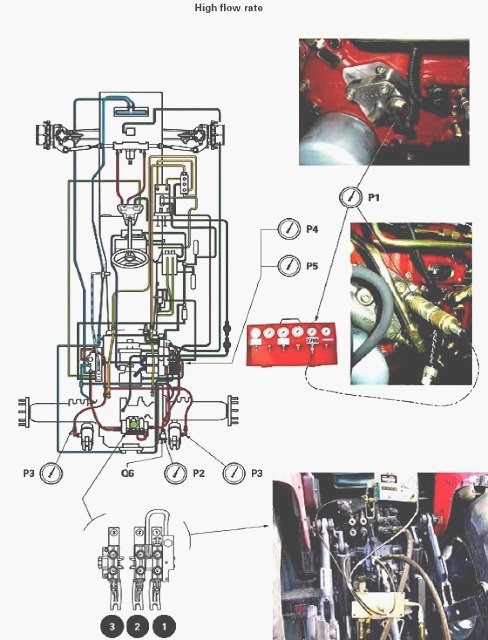

MF 6170, 6180 high flow rate system

Safety valve test - Connect a pressure gauge with a coupler to the

diagnostics connector.

This diagnostics connector is located:

- either on the trailer brake valve (if fitted);

- or on the cover plate (2) fitted to the right-hand hydraulic cover

plate.

- Run the engine at 2200 rpm.

- Activate an auxiliary spool valve to open the valve.

- Check P1 = 195 ± 5 bar.

If pressure P1 is not correct, adjust the safety valve using shim(s) -

At 1000 rpm, the pressure should not drop.

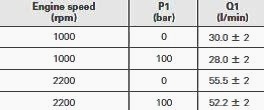

Checking the flow rate of the pump

- Connect a flowmeter to the quick coupling of an Massey Ferguson 6170,

6180 auxiliary spool valve other than the one supplied by the flow

divider. Connect the

return directly to the housing via the transmission filler port.

- Connect a suitable pressure gauge to the diagnostics connector. Check

that the flowmeter load valve is open fully.

- Activate the spool valve.

- Adjust the flowmeter load valve to obtain P1. Do not consider the

value of the pressure gauge fitted to the flowmeter. Look at the

separate pressure gauge

connected to the diagnostics connector.

- Check Q1.

Checking the flow divider (if fitted)

Connect a flowmeter to a quick coupling on auxiliary spool valve no.1

located by the flow divider "D".

Connect the return directly to the housing via the transmission filler

port.

Connect a suitable pressure gauge to the diagnostics connector. Check

that the flowmeter load valve is open fully.

Activate the spool valve. Adjust the flowmeter load valve to obtain P1.

Check the flow rate of the divider by turning the adjusting knob

shown. Check Q2.

Engine speed (rpm) - 2200

P1 (bar) - 0 to 150

Q2 (l/min) - 0 to 53

Do not consider the value of the pressure gauge fitted to the flowmeter.

Look at the separate pressure gauge connected to the diagnostics

connector (1).

Checking Kick-out pressure on an auxiliary spool valve fitted with

automatic return to neutral

Connect a flowmeter to the relevant spool valve.

Connect a suitable pressure gauge to the diagnostics connector (1).

Run the engine at 2200 rpm.

Activate the MF 6255, 6270 spool valve in automatic return position.

Release the lever and gradually shut the flowmeter load valve until the

lever returns to neutral position.

Check the Kick-out pressure: P1 = 150 - 170 bar.

Make sure that the spool valve is in the automatic return position and

not in the floating position. Do not consider the value of the pressure

gauge fitted to the

flowmeter. Look at the separate pressure gauge connected to the

connector (1).

Checking the pressure and flow rate of the trailer brake

Pressure

- Connect a pressure gauge to the trailer brake connector.

- Run the engine at 2200 rpm.

- Lock the brake pedals together and apply a progressive force.

The pressure read should increase gradually until it reaches P2 = 130 -

150 bar maximum.

Flow rate

- Connect a flowmeter to the trailer brake connector.

- Connect the return directly to the housing via the transmission filler

port.

- Run the engine at 2200 rpm.

- Activate the coupled brake pedals.

- Check Q6 = 24 - 31 l/min.

Testing the linkage security valve

- Disconnect the supply hose pipes on the rams and connect them to a

manual pump.

- With the engine stopped and the linkage valve in neutral position,

inject pressure into the system.

- Check the valve opening pressure: P3 = 200 - 210 bar.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader