________________________________________________________________________________

Massey Ferguson 6290, 6270 transmission - Mechanical reverse shuttle

Massey Ferguson 6290, 6270 tractors may be fitted with a Heavy gearbox featuring a mechanical reverse shuttle.

The reverse shuttle transmits movement commanded at the Dynashift into

the transfer shaft installed at the front of the main gearbox, by the

action of the dual gear.

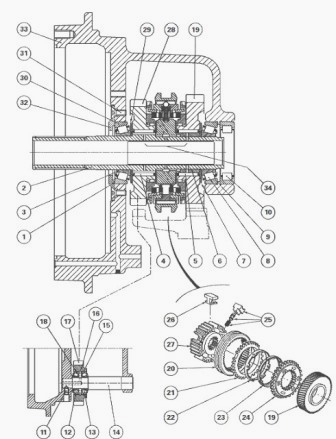

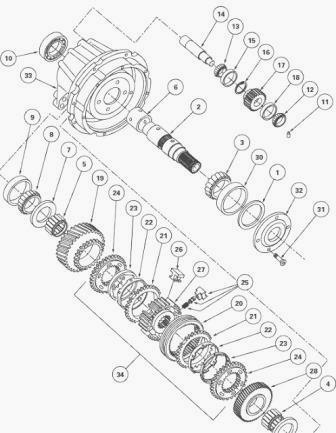

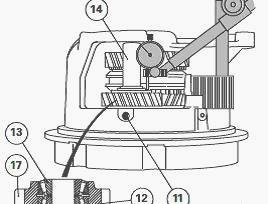

MF 6290, 6270 transmission - Mechanical reverse shuttle

(1) Shim(s) (2) Secondary shaft (3) Bearing cone (4) Needle roller

bearing (5) Needle roller bearing (6) Bush (7) Washer (8) Bearing cone

(9) Bearing cup (10) Roller bearing (11) Screw (12) Bearing cone (13)

Bearing cone (14) Idling gear shaft (15) Bearing cup (16) Spacer ring

(17) Reverse-drive idling gear (18) Bearing cup (19) Forward drive gear

(20) Synchromesh slide (21) Rings (22) Rings (23) Cones (24) Synchromesh

flanges (25) Locking device (26) Shoes (27) Synchromesh hub (28)

Reverse-drive gear (29) Washer (30) Bearing cup (31) Screw (32)

Retaining plate (33) Housing (34) Synchromesh assembly

The reverse shuttle assembly is located in the rear cavity of the input

housing behind the Dynashift.

It includes:

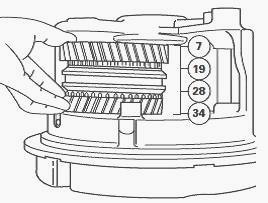

- two helically cut pinions (19) and (28) installed on two needle

bearings (4) and (5). These pinions are respectively in constant

engagement with the dual gear at the

box main input drive and reverse-drive idling gear (17)

- twin-cone synchromesh assembly (34), the hub is locked by the splines

on secondary shaft (2)

- a synchromesh-control selector rail and fork assembly.

- secondary shaft (2) installed on two tapered roller bearings supported

by two bearings in the input housing

- reverse drive idling gear (17) rotating on two tapered roller bearings

installed on shaft (14) mounted in two bores in the housing.

The latter gear is in constant engagement with the front teeth of the

gearbox dual input gear.

When the synchromesh slide is over on the right, it transmits movement

to forward drive gear (19) in direct connection with the rear teeth of

the gearbox dual input

gear.

Reverse drive

Forward-drive gear (28) is in constant engagement with idling gear (17)

which meshes with the front teeth of the gearbox dual input gear.

Split the Massey Ferguson 6270, 6290 tractor between the engine and

gearbox.

Drain the gearbox and the intermediate housing.

Visually identify the contour of the plugs.Remove the hydraulic clutch.

Remove the selector cover.

Remove the input housing.

Disassemble the locking device, the selector rail and the reverse

shuttle fork.

Place the housing on a work bench in the vertical position. Remove the

sling.

Disassemble the Dynashift.

MF 6290, 6270 gearbox reverse shuttle repair

Remove screws (11), extract shaft (14). Remove gear (17) and bearing

cones (12) and (13).

Drive out cups (15) and (18). Remove spacer ring (16).

Pair the cones and cups if they are to be reused.

Remove screws (31). Remove retaining plate (32), shims (1) and cup (30).

Extract secondary shaft (2).

Remove the assembly comprising pinions (19) and (28), synchro (34) and

washer (7).

Remove cone (8) and cup (9).

Separate the following parts on the pinion or synchromesh assembly: gear

(19), bush (6), needle roller bearings (5), cones (23), rings (21),

rings (22), synchromesh

flanges (24), gear (28) and needle roller bearings (4).

If necessary, withdraw cone (3) from the shaft, remove washer (29), and

drive out roller bearing (10).

Clean and check the parts and replace any that are faulty.

Check that the pipes and ports in secondary shaft (2), shaft (14),

housing (33), synchromesh (34) and bush (6) are not blocked.

Ensure that the plug (rivet) is crimped into the housing, on the end of

the lube pipe to the reverse drive idling gear.

If necessary, overhaul synchromesh (34).

If it was removed, refit washer (29) on shaft (2) then fit cone (3) in

abutment on the washer, using a press and a suitable fixture.

Lubricate the shaft, the cones and the bearing cups.

Assemble gear (19) and bush (6) by positioning the inner recess towards

drive hub (27) of the assembly comprising (34), needle roller bearings

(5), cones (23),

rings (21), rings (22), synchromesh flanges (24), gear (28) and needle

roller bearings (4).

Refit the assembly comprising pinions (19) and (28), synchro (34) and

washer (7).

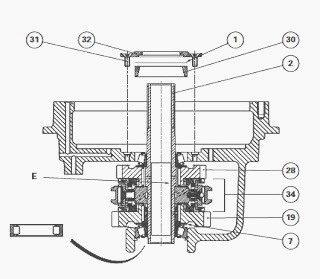

Centre the washer. Insert secondary shaft (2) through the front bore in

the housing, into the pinion / synchro assembly.

Install shaft (2), with shoulder E in contact with the synchromesh hub.

If shimming of the secondary shaft proves to be necessary, otherwise

continue the assembly operation.

Install cup (30), shims (1) and retaining plate (32).

Coat screw (31) with Loctite 241 or equivalent; install and torque to 25

- 32 Nm.

Manually check the axial play and rotation of pinions (19) and (28) and

shaft (2).

If shimming of the reverse-drive idling gear proves to be necessary.

Install idling gear fitted with spacer ring (16), bearing cones

(12) (13) and shaft (14).

Apply a light quantity of Loctite 241 or equivalent to screw (11);

install and torque to 40 - 56 Nm.

Check with fingers for normal backlash of gear (17) and rotation of the

complete gear train.

Install roller bearing (10).

Preparing and shimming the secondary shaft

Position the housing in a vice.

Calculate shim thickness E (1) to obtain a temporary clearance of 0.10

to 0.20 mm maximum.

Position cup (30), shims (1) as calculated earlier, and retaining plate

(32).

Install and provisionally tighten screw (31) without Loctite to 25 - 32

Nm.

Place the feeler of a dial gauge on the extremity of shaft (2).

Exert a hard pull on the shaft, rotating it alternately right and left

in order to correctly seat the cones in the bearing cups.

Adjust the dial gauge pointer to zero.

Depending on the clearance value J obtained, select a new thickness of

shims C (1) to obtain a preload: P1 = 0.10 to 0.20 mm According to the

formula: C = E + J

+ P1.

If possible, set at the top value of the tolerance.

Remove screw (31), remove retaining plate (32).

Install final shims (1) selected at operation 42, on cup (30). Reinstall

the retaining plate. Install and torque screw (31).

Preparing and shimming the reverse drive idling gear

Position the housing in a vice.

Install minimum spacer ring (16) in the groove of gear (17) then fit

cups (15) and (18) in abutment on

the segment.

Position gear (17) and cones (12) and (13) on the housing. Slide shaft

(14).

Install screw (11) without Loctite, and torque to 40-56 Nm.

Adjust shims to obtain a clearance: J2 = 0.05 to 0.18 mm.

Apply the feeler of a dial gauge to gear (17).

Exert a hard push on the gear, alternately rotating to right and left in

order to seat the cones correctly in the cups.

Adjust the dial gauge to zero.

Depending on the value read on the dial gauge, select the definitive

spacer ring (16) to obtain J2.

If necessary, remove gear (17). Drive out cups (15) and (18). Remove

spacer ring (16). Install the spacer ring selected at operation 54.

Install the cups. Reinstall the

gear. Repeat operation 30.

Coat screw (11) with Loctite 241 or equivalent, install and definitively

torque to 40 - 56 Nm.

Check with fingers for normal backlash at gear (17) and rotation of the

gear train.

Reassemble the Dynashift

Reassemble the reverse shuttle fork, the selector rail and the locking

device.

Install the input housing.

Install the selector cover.

Install the hydraulic clutch (pressure loaded).

Reassemble the MF 6270, 6290 tractor between the engine and gearbox.

Service the oil in the sumps and check the level on the sight glass

located on the left of the centre housing.

If necessary, bleed the hydraulically controlled clutch.

Proceed to road test of all Dynashift controls.

Check the leak tightness of the hydraulic connections and the mating face of the selector cover.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader