________________________________________________________________________________

Massey Ferguson 6480,6490 gearbox - PowerShuttle control unit

The unit fixed to the right-hand side and front of the Massey Ferguson

6490, 6480 gearbox carries out two hydraulic functions quite separate to

the input unit.

It controls:

- the power shuttle,

- the Dynashift.

The channels and ducts machined in the unit allow oil under pressure to

be directed to the reverse shuttle proportional solenoid valves and the

Dynashift solenoid

valves EV1 and EV2.

All solenoid valves are controlled respectively by

the MF 6480, 6490 tractor electronic system. A 60 micron filter element

(8) is located under

the right-hand hydraulic cover, upstream from the control unit. This

additional filter supplies clean oil to the spool of each solenoid

valve.

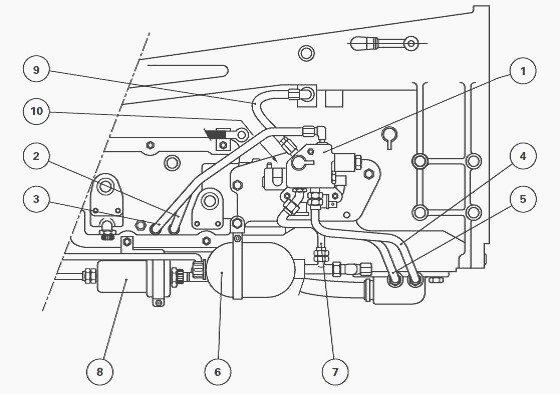

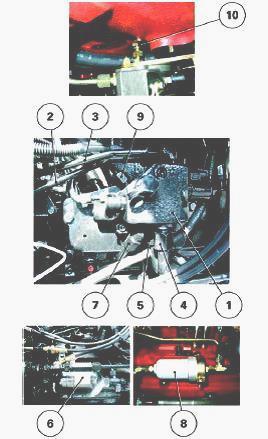

Control unit and hydraulic lines

(1) Control unit (2) Return to reverse clutch housing (3) Return to

forward clutch housing (4) Reverse shuttle: 17 bar supply line to

forward clutch (5)

Reverse shuttle: 17 bar supply line to reverse clutch (6) Accumulator

(Nitrogen) (7) Main 17 bar supply line (8) 60 micron filter element (9)

Dynashift: to internal

forward clutch line (17 bar) (10) Dynashift: to internal reverse clutch

line (17 bar)

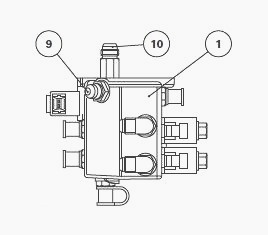

Massey Ferguson 6480, 6490 Power Shuttle Control

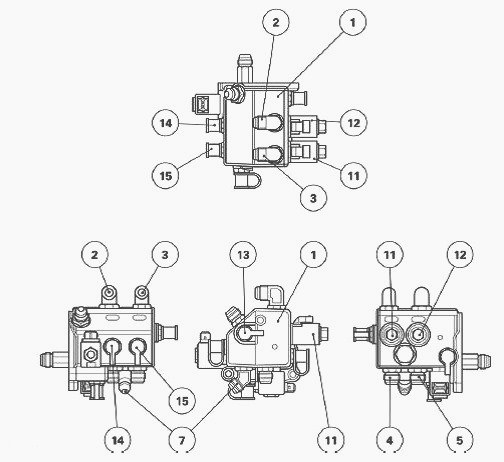

Identification of ports on control unit

(1) Control unit (2) Return to reverse clutch housing (3) Return to

forward clutch housing (4) Pressure outlet to forward clutch (5)

Pressure outlet to reverse clutch

(7) Control unit main supply (17 bar) (13) Control unit pressure

connector (14) Reverse clutch pressure connector (15) Forward clutch

pressure connector

Each of the hydraulic return lines of the proportional solenoid valves

(11) and (12) has separate channels. This design avoids any back

pressure from one solenoid

valve to another.

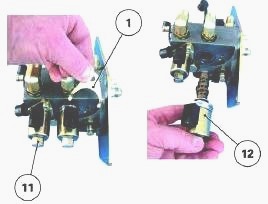

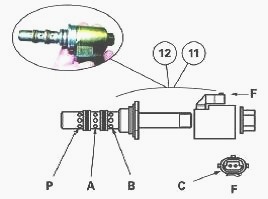

Proportional solenoid valve

Removal

Remove flange (1).

Drive off the solenoid valve (11) or (12) by gently applying pressure

with a screwdriver between the valve and the unit.

Install

Check the condition and cleanliness of the O’rings fitted on the

solenoid valve.

Position and manually drive the solenoid valve into its housing, beyond

the point of resistance (O’rings squeezing).

Position the flange. Tighten the screw from 8 to 11 Nm.

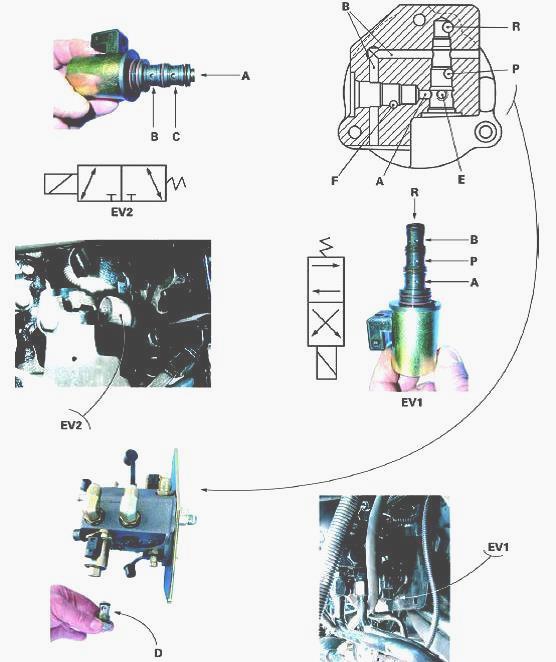

Identification of ports on a proportional solenoid valve

A - Clutch supply ports, B - Clutch return ports, P - 17 bar pressure, C

- Solenoid supply

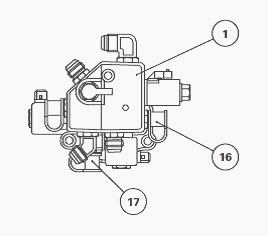

MF 6490, 6480 Dynashift control

Identification of ports on control unit

(1) Control unit (9) Pressure outlet to forward clutch (10) Pressure

outlet to reverse clutch (16) Forward clutch pressure connector (17)

Reverse clutch pressure

connector

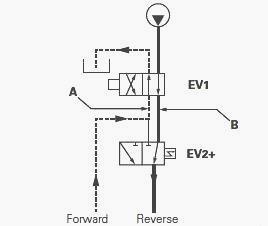

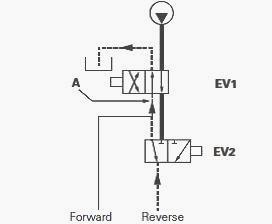

In the control unit, the Dynashift part includes two internal channels A

and B which allow oil to circulate from one solenoid valve to the other.

The four Dynashift

ratios are managed by two solenoid valves.

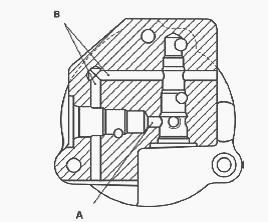

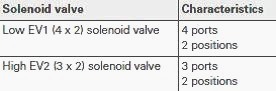

Characteristics of the solenoid valves

Identification of ports

C - To port F, D - Non-return valve, E - Port to front piston, F - Port

to rear piston, P - 17 bar pressure, R - Return

The removal and install procedure for solenoid valves EV1 and EV2 is the

same as that for a proportional solenoid valve.

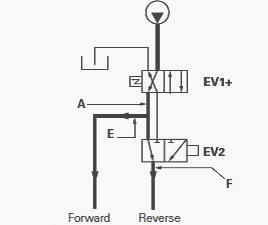

Explanation of Dynashift ratios

Ratio A

Ratio A is obtained when solenoid valve EV1 is supplied. Oil under

pressure can also reach channel A.

Channel A directs the oil to the front piston via port E and to solenoid

valve EV2.

As this is in neutral position, the oil can pass through the

spool and port F to the

chamber of the rear piston. The two pistons are therefore under

pressure.

Ratio B

Ratio B is obtained when the two solenoid valves are supplied. Therefore

the flow of oil to the rear piston is interrupted.

The rear piston is

pushed out by springs

which send the oil into channel B. This channel is

joined to the housing by solenoid valve EV1.

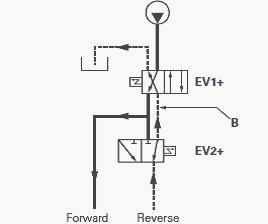

Ratio C

Ratio C is obtained by switching off solenoid valve EV1, while

maintaining solenoid valve EV2 under voltage. Channel A is no longer

pressurised but is connected to

the housing.

As a result, the front piston

can return to neutral position. Channel B is under pressure. The oil

flows to the rear piston via solenoid valve EV2.

Ratio D

Ratio D is obtained by switching off EV2. The two solenoid valves are at

rest. The two pistons are connected to the housing via channel A.

Removing and install the control unit

Mark and disconnect the connectors on solenoid valves EV1 and EV2 of the

Dynashift as well as those of the proportional solenoid valves (12) (11)

of the power

shuttle forward and reverse clutches.

Disconnect and remove pipes (2), (3), (4), (5), (7) and (9). To prevent

oil flowing from the gearbox, it is advised to disconnect the return

pipes (2) and (3) at their

higher connections.

Unscrew the support (1) from the MF 6480, 6490 gearbox. Remove the

“support and unit” assembly by gradually unscrewing the union (10)

(Dynashift reverse

clutch supply).

Install the “support and unit” assembly. Tighten:

- the screws fixing the support to the gearbox to 50 - 70 Nm,

- the screws fixing the unit to the support to 25 - 35 Nm.

Reconnect the pipes and connectors.

If it was necessary to replace the control unit or proportional solenoid

valves, test:

- the 17 bar pressure of the unit,

- the Dynashift clutch pressures,

- the pressure of the reverse shuttle forward and reverse clutches.

When pressurised, the reverse shuttle clutches must be calibrated using

Wintest.

Carry out a road test of the hydraulic functions affected by the repair

work.

Check the oil tightness of the hydraulic unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader