________________________________________________________________________________

Massey Ferguson 6460, 6465 hydraulic system - Block valves for steering and low pressure

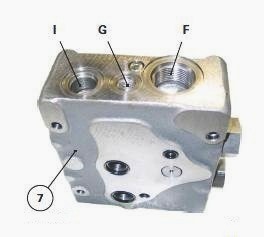

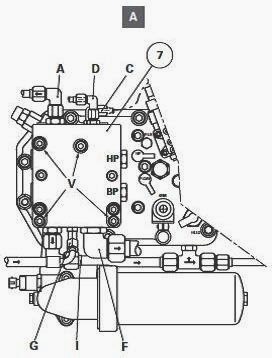

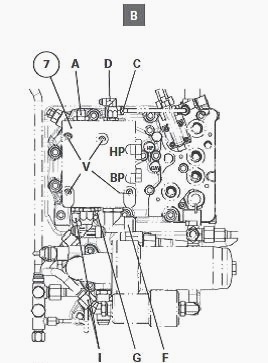

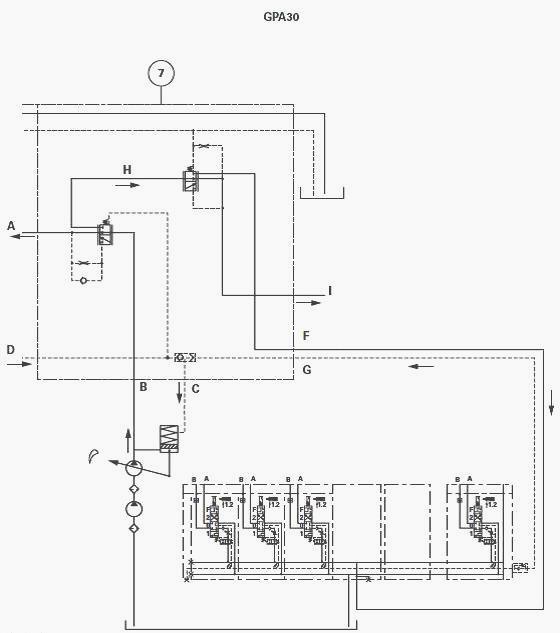

Valves block

The single valves block (7), Installed to the right-hand hydraulic cover

plate (8), is fitted to 40 kph tractors without trailer braking. Valves

block has two spools and

receives the flow rate from the variable displacement pump.

It ensures

priority for the Massey Ferguson 6465, 6460 steering system and the 17

or 21 bar low

pressure system. The oil is then directed to the auxiliary spool valves

and linkage spool valve.

This section primarily describes the single block valves (7) without

trailer braking.

The hydraulic unit with two priority blocks and with 40

kph trailer braking or trailer

braking for MF 6460, 6465 tractors fitted with a high-pressure braking

unit is described in its own section.

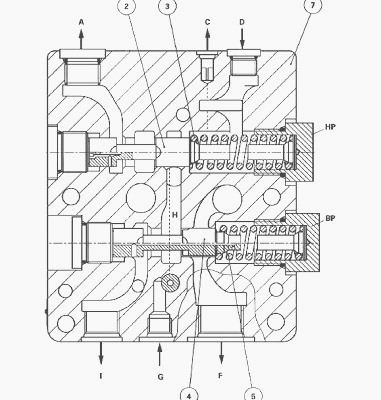

Identification of 110 l/min or 150 l/min Load Sensing (LS) ports

on the single valves block

A - Orbitrol supply, B - High pressure (HP) supply from variable

displacement pump (drilled port on the mating face of priority block and

cover plate), C - LS pilot

flow to the variable displacement pump hydraulic regulator, D - LS pilot

flow from the Orbitrol, F - Spool valve (auxiliary and linkage) supply,

G - LS pilot flow from

spool valves (auxiliary and linkage), H - Internal channel, I - 17 or 21

bar outlet, J - Plug, HP - High-pressure (HP) spool, BP - Low-pressure

(BP) spool

1st position - Steering

The spool (2) moves to the left under the action of spring (3).

The flow

coming from the variable displacement pump via channel B is by priority

directed towards the

Orbitrol spool valve via channel A.

Steering at neutral:

The steering spool valve (Orbitrol) is in closed position. The pump

pressure moves spool (2) to the right and the flow is directed into

channel H.

Steering activated:

A pilot flow pressure from the Orbitrol arrives at port D and pushes the

spool (2) to the left, allowing the flow to enter port A and supply the

Orbitrol.

A flow of approximately 0.5 l/min is directed through port A towards port D via a drilled hole and restrictor in spool (2). This flow rate creates pressure of approximately 6 bar at port D.

The LS line directs this pressure to the variable

displacement pump regulator which is adjusted to 22 bar in order to

obtain a standby pressure of 28 bar.

2nd position - 17 or 21 bar pressure control valve

The spool (4) moves to the left under the action of the spring (5),

allowing the flow from channel H to be directed into port I (17 or 21

bar low pressure).

As soon as the pressure in this port reaches 17 or 21 bar, the spool reaches equilibrium thus allowing the low pressure to be maintained and the flow to be directed towards port F (linkage and auxiliary).

When the linkage and auxiliary spool valves

are used, an LS pilot flow pressure is sent to the block via port G to

join the LS line at port C.

Checking after servicing

If the single priority block (7) had to be replaced:

- Lightly smear the thread of screws V with Loctite 542 or equivalent.

Tighten these screws to a torque of 25 - 35 Nm.

- Carry out hydraulic tests.

Check the tightness of the unions and "O" rings fitted between the

single priority block and the right-hand hydraulic cover plate. Carry

out a road test.

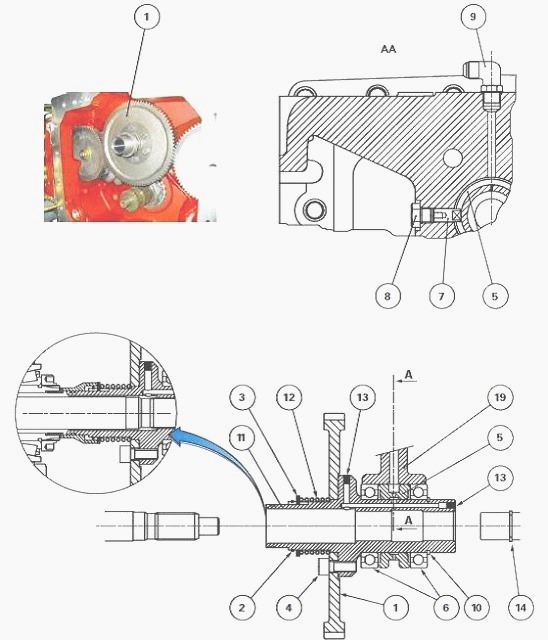

MF 6465, 6460 hydraulic pump drive bearing - Repair operation

Disconnect the Massey Ferguson 6460, 6465 tractor between the gearbox

and the intermediate housing.

Remove the components of the creeper unit (if fitted) that might hinder

the removal of the hydraulic pump drive gear.

Remove:

- the stop ring (2)

- the tab washer (3)

- the spring (12)

- the drive gear (1) fixed to the bearing (11)

Removing the bearing

Unscrew the plug (8).

Pull the pin (7) using a threaded rod, such as to free the spacer (5);

Pull the bearing (11) such as to remove it from its bore through the

front of the intermediate housing.

Reinstall the bearing

Check neither the channel nor drilled hole in the spacer (5) is blocked;

Check the circlip (14) is present on the upper PTO shaft. Reinstall the

bearing (11).

Position the groove of spacer (5) along the axis of the port provided

for plug (8).

Slide the pin (7) into its bore, inserting its flat sections into the

groove of the spacer (5). Tighten the plug (8).

Ensure that the bearing is correctly held by the pin (7) and that it

rotates freely. Reinstall the gear (1).

Lightly smear the thread of the screws (4) with Loctite 242 or

equivalent. Tighten these screws to 72-96 Nm.

Reinstall:

- the spring (12)

- the tab washer (3)

- the stop ring (2)

Disassembling the hydraulic pump drive bearing

Remove the circlip (10). Extract the rollers (6) from the bearing.

Remove the spacer (5).

Reassembling the bearing

Clean and check all components. Replace those that are defective. Using a press and a suitable fixture, insert the rollers (6), separated by the spacer (5), into the bearing (11).

The force of the press must be applied to the internal ring of the rollers. Reinstall the circlip (10).

The rollers of the hydraulic pump drive

bearing

(11) are lubricated by an oil flow from the right-hand hydraulic cover

plate via the union (9). Install and adjust the creeper unit components.

Reconnect the tractor between the gearbox and the intermediate housing. Carry out a road test of all controls. Check the tightness of the mating faces and hydraulic unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader