________________________________________________________________________________

Massey Ferguson 6455, 6470 hydraulic low pressure valve - Open Centre

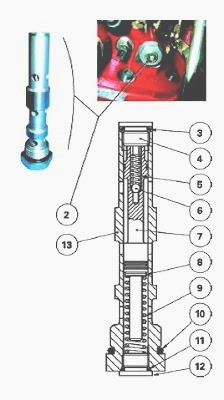

The Massey Ferguson 6470, 6455 low pressure valve (17 bar) (2) is

screwed onto the left-hand hydraulic cover.

It performs the following functions:

- it supplies oil and maintains pressure in the 17 bar low pressure

circuit

- it supplies the cooling system (5 bar) and lubricating system (1.5

bar).

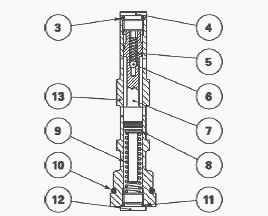

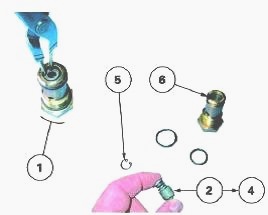

(2) 17 bar valve (3) O’ring (4) Plug (5) Spring (6) Ball (7) Spool (8)

Shim(s) (9) Spring (10) O’ring (11) Seal (12) Plug (13) Valve sleeve

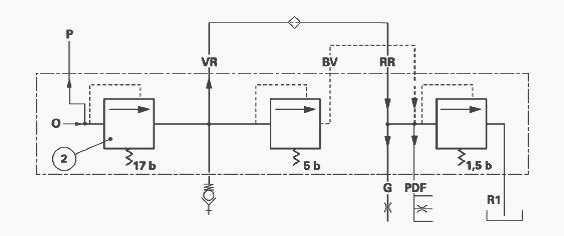

Identification of ports

G - Brake master cylinder booster (excluding Meritor type), O - Valve

supply via the steering spool valve return (Orbitrol), P - Outlet to low

pressure parts, R1 -

Return (1.5 bar valve), BV - Lubrication to 1.5 bar valve (cold oil), RR

- Lubrication - cooling system return, VR - Lubrication to cooling

system, PDF - Lubricating

line to rear PTO

Description of the MF 6455, 6470 17 bar low pressure valve

As soon as the engine is started, the return oil from the steering unit

(Orbitrol) enters port O and exits by port P of the left-hand cover.

It is directed towards the low pressure circuit of the right-hand

hydraulic cover in order to supply:

- power shuttle (if fitted)

- dynashift unit

- changing between Hare / Tortoise range

- 4WD clutch

- front and rear differential locks

- rear PTO brake and clutch

- front power take off (if fitted).

A back pressure is generated in the low pressure circuit, forcing the

ball from its seating and thereby compressing the spring. The oil passes

into the rear of the

spool, creating a pressure which progressively moves it downwards by

compressing the spring which thrusts against the shims.

When one of the low pressure functions is activated, the momentary drop in pressure returns the ball to its seating through the action of the spring.

The oil contained

in the chamber at the front of the plug flows through a drain port

located at the end of the spool. Leaks return to the housing via port R

in the cover.

MF 6470, 6455 low pressure valve (17 bar) repair

It is not necessary to remove the left-hand hydraulic cover to carry out

work on the valve.

Removal

Remove any parts around the valve that may obstruct work.

Remove and separate the valve (2) from the left-hand hydraulic cover.

Install

Check the condition of the O'ring (10) and replace if necessary.

Screw the valve back onto the cover and tighten to 40 - 55 Nm.

Disassembly

The valve comprises several hydraulic parts (spool, springs and ball)

which cannot be replaced separately. Remove the O'ring (10).

Tighten the hexagonal head of the valve in a vice with protective jaws.

Gradually unscrew the plug (12) and discard the O'ring (11).

Recover: spring (9), shim(s) (8).

Gradually unscrew the plug (4) and discard the O'ring (3).

Recover: spring (5), ball (6).

Remove the spool (7) by carefully tapping the shaft (13) against a

wooden shim.

Reassembly

The hydraulic parts must be reassembled on a clean work surface clear of

filings and dirt.

Check:

- the condition of the springs and O’rings

- the absence of scratches or seizing on the moving parts of the valve

- the sliding of the spool in its sleeve

- the cleanliness of the ports.

Conclusion - If the valve is defective, replace it. If not, reassemble

it by carrying out the disassembly operations in reverse order.

Adjusting the Low pressure valve (17 bar)

- It is not necessary to remove the left-hand hydraulic cover to adjust

the valve.

- When the valve is removed, it can be adjusted inserting shims (8)

between the spool (7) and the spring (9).

Operation of the cooling system

The pressure acting on the back of the spool pushes it towards the

bottom of the valve, pressing in the spring. It then allows oil to pas

to port VR and the cooler.

When it leaves the cooler, the oil is directed to the Massey Ferguson

6455, 6470 transmission lubricating system via the 1.5 bar valve.

5 bar valve

When the oil is cold, the 5 bar valve opens partially. It then allows

some oil to pass directly to port BV of the left-hand cover, and to

supply the transmission

lubricating system, without really entering the cooler.

Assembling the Low pressure valve (5 bar)

It is not necessary to remove the left-hand hydraulic cover to carry out

work on the valve. Remove the pipe and union.

Place the valve, spring and threaded ring in the cover.

Compress the spring, tightening the threaded bush until it reaches a

“hard point” (the bush has reached the cover shoulder).

After assembly, check that free movement of the valve and the

compression of the spring, entering a screwdriver through the port

provided for screwing in the

temperature switch, located on the lower part of the cover.

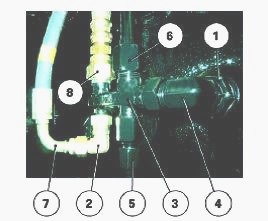

Description of the 1.5 bar lubricating valve

The 1.5 bar valve is hidden behind the fuel tank, and is located at the

front left-hand side of the gearbox.

It controls the oil coming from the cooling circuit, and maintains a

lubricating pressure of approximately 1.5 bar in the circuit, due to the

valve setting. If the pressure

exceeds 1.5 bar, the spring compresses, the valve moves and oil flows to

the return R1.

When the requirements of the low pressure circuit are met, oil is

channelled towards the booster port of the brake master cylinders in

order to ensure a constant oil

level.

Considering the available hydraulic options, other assemblies can

be carried out on the union. Example: Front PTO - Meritor brake master

cylinders.

1.5 bar valve repair

Removal

Remove the part(s) that may obstruct work on the valve (1).

Mark and disconnect the pipes (5) (6), hoses (7) (8) and unions (2) (3)

(4).

Remove the housing valve from the MF 6455, 6470 gearbox.

Refitting

Replace the O’rings if necessary.

Reinstall the valve, unions, hoses and pipes.

Replace any part(s) removed at operation.

Disassembly and Reassembly

Take off circlip (5). Remove the bush (2), spring (3) and valve (4) from

the valve body (6).

The valve (1) consists of several hydraulic parts (valve, spring) listed

in the spare parts catalogue.

Check that the hydraulic parts are clean.

Reassemble the valve, carrying out operation in reverse order.

Manually check the free movement of the valve.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader