________________________________________________________________________________

Massey Ferguson 6612, 6613 Dyna-4 transmission - powershift module

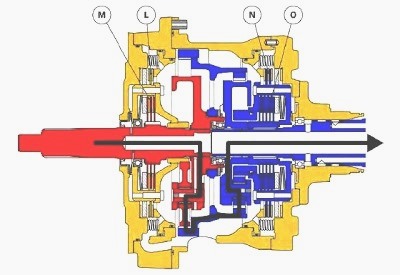

The Powershift module is fitted on Massey Ferguson 6613, 6612 gearbox (GBA25). It is fitted at the gearbox input and is driven directly by the engine.

This module provides Dyna-4 transmission with four ratios for shifting under load. These four ratios are provided by two epicyclic gear trains, operating with two brakes and two clutches.

The ratios can be controlled with the Power control lever (to the left

under the steering wheel) or with the right-hand armrest lever.

Ratios are shifted in "Speed matching" mode, where the most suitable

ratio for shifting under load is automatically selected when changing

range.

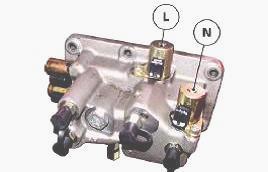

The brakes and clutches are controlled by proportional solenoid valves

(N and L). They are fitted to a hydraulic unit to the front right of the

gearbox that operates on the tractor 20 bar circuit.

Principles of operation

The MF 6612, 6613 tractor gearbox powershift module is made up of two

epicyclic gear trains:

- The front epicyclic gear train, located on the gearbox input. This

comprises a sun gear (36), a planet carrier (25), three planetary gears

(48) and a ring gear (65). It

is controlled by a brake and a clutch. Its ratio is 1.23/1 (speed

multiplied) or 1/1 (train locked).

- The rear epicyclic gear train, located on the gearbox output. This

comprises a sun gear (49), a planet carrier (30), three planetary gears

(50) and a ring gear (29). It

is controlled by a brake and a clutch. Its ratio is 1/1.5 (speed

reduced) or 1/1 (train locked).

Front epicyclic gear train

The input shaft (10) of the module is linked to the planet carrier (25)

of the primary epicyclic gear train.

The sun gear (36) is either attached to the planet carrier (25) (clutch M engaged, epicyclic gear train locked) or to the gearbox housing (brake L engaged, input speed multiplied).

Drive is transmitted

by ring gear (65) to ring

gear (29) of the rear epicyclic gear train.

Rear epicyclic gear train

Input drive is transmitted by the ring gear (29).

The sun gear (49) is either attached to the planet carrier (30) (clutch O engaged, epicyclic gear train locked) or to the gearbox housing (brake N engaged, input speed reduced).

The output shaft

(47) is attached to the planet carrier (30), and is linked to the Power

Shuttle.

Lubrication

The Powershift module is lubricated under pressure by a network of

internal channels.

Oil enters the upper main shaft of the gearbox, then travels through radial bores to the elements to lubricate.

The oil flows from the tractor

hydraulic circuit.

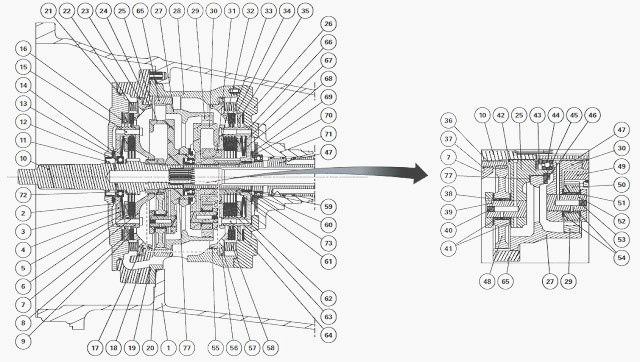

MF 6612, 6613 Dyna-4 transmission powershift module

(1) Housing (2) Cover (3) Clutch M housing (4) Belleville washer (5)

Discs (6) Thrust plates (7) Clutch M cover (8) Discs (9) Thrust plate

(10) Input shaft (11) Lip

seal (12) Ball bearing (13) Friction washer (14) Friction washer (15)

Screws (16) Clutch M/brake L junction plate (17) Brake L piston (18)

Powershift module front

housing (19) "O" ring (20) "O" ring (21) "O" ring

(22) Spring (23) "O" ring (24) "O" ring (25) Front planet carrier (26)

Cover (27) Ring gear carrier (28) Rear housing (29) Rear ring gear (30)

Rear planet carrier (31)

Snap ring (32) Clutch O cover (33) Discs (34) Thrust plates (35) Clutch

O/brake N junction plate (36) Sun gear (37) Snap ring (38) Needle

bearing (39) Pin (40) Plug

(41) Friction washers (42) Snap ring (43) Bronze spacer

(44) Ball bearing (45) Spacer (46) Circlip (47) Output shaft (48)

Planetary gear (49) Sun gear (50) Planetary gear (51) Needle bearing

(52) Pin (53) Plug (54) Friction

washers (55) "O" ring (56) "O" ring (57) Brake N piston (58) Spring (59)

Snap ring (60) Ball bearing (61) Clutch hub

(62) Thrust plates (63) Discs (64) Screws (65) Front ring gear (66)

Clutch O housing (67) Belleville washer (68) Belleville washer (69)

Friction washer (70) Spacer

(71) Bearing (72) Spring washer (73) Needle bearing (74) "O" ring (75)

"O" ring (76) "O" ring (77) Washer

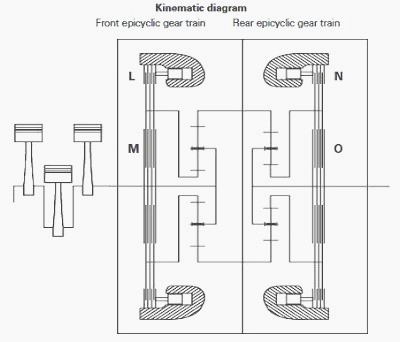

Kinematics

(Av) Forward clutch, (Ar) Reverse clutch, (L) Sun gear brake, front

epicyclic gear train of Powershift module, (M) Sun gear clutch, front

epicyclic gear train of

Powershift module, (N) Sun gear brake, rear epicyclic gear train of

Powershift module, (O) Sun gear clutch, rear epicyclic gear train of

Powershift module

Logic of the ratios

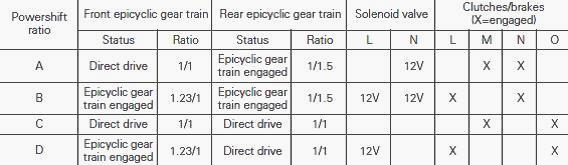

The four ratios are obtained by combining the two epicyclic gear trains.

The front epicyclic gear train multiplies the input speed to 1.23/1,

while the rear epicyclic gear

train reduces the speed to 1/1.5.

Each epicyclic gear train may be

engaged (multiplication or reduction) or locked (ratio 1/1). The two

epicyclic gear trains are used

in combination to obtain the four ratios A, B, C and D.

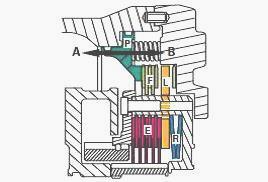

Clutch / brake operation

The brakes and clutches operate as a 1 brake/1 clutch set. The brakes

(F) mesh an element to the housing (fixed), and the clutches (E) mesh

two elements in

rotation.

The Massey Ferguson 6612, 6613 tractor clutches/brakes are controlled by a single piston (P).

A junction plate (L) allows the clutch to be released when the brake is engaged, and vice versa. When there is no pressure on the piston (position A), the Belleville washer (R) engages the clutch (E).

When the piston (P) is

actuated (position B), it engages the brake (F) and pushes back the

Belleville washer (R) via the plate (L).

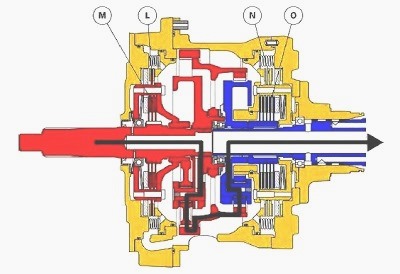

Ratio A (1/1.5)

Brake piston "L" is not pressurised, clutch "M" is engaged and locks the

front epicyclic gear train. Brake piston "N" is pressurised.

The sun

gear of the rear epicyclic

gear train is held in relation to the gearbox housing, enabling the rear

epicyclic gear train to reduce the input speed.

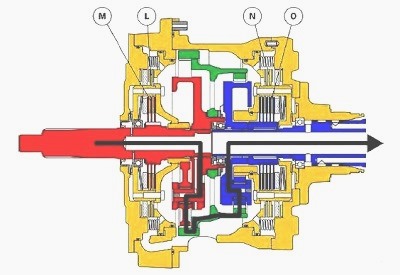

Ratio B (1/1.22)

The two brake pistons L and N are pressurised. The sun gears are held in

relation to the MF 6613, 6612 gearbox housing. The two epicyclic gear

trains are

engaged.

The front epicyclic gear train increases the input speed to

1.23/1 and the rear epicyclic gear train reduces the speed to 1/1.5,

giving an overall ratio of

1/1.22.

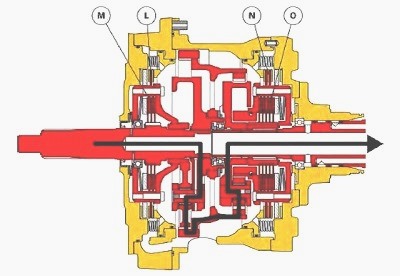

Ratio C (1/1)

None of the pistons is pressurised, clutches "M" and "O" are engaged by

their respective Belleville washers.

Both epicyclic gear trains are

locked and the input

speed is identical to the output speed.

Ratio D (1.23/1)

Brake piston "L" is pressurised, it holds the sun gear of the front

epicyclic gear train in relation to the housing.

The front epicyclic gear train multiplies the input speed to 1.23/1.

Brake piston N is not pressurised. Clutch "O" locks the rear epicyclic gear train; its ratio is 1/1.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader