________________________________________________________________________________

Massey Ferguson 7499, 7495 load sending auxiliary mechanical spool valves

Massey Ferguson 7495, 7499 tractor proportional auxiliary spool valves, of the Bosch/Rexroth SB23 LS type, are fitted to the high flow rate high pressure circuit.

They are fed by the oil coming from the priority block(s). When no

functions are being activated, the entire flow rate is directed towards

the spool valves.

If certain priority functions are being supplied, the remaining flow is

then available for the auxiliary spool valves. E

ach spool valve has a flow regulating system controlled by a black, red,

green or yellow button located directly on the each spool valve

regulating valve system.

The main spool of the valve is controlled by a cable linked to a lever

in the cab. The spool directs oil towards either outlet port.

Each outlet port is linked to the LS pilot line of the variable

displacement pump regulating valve via the priority block(s).

The auxiliary spool valves are made up of elements themselves containing

spools and valves. Some elements cannot be identified as spare parts.

Different types of MF 7499, 7495 spool valve

block components

A spool valve block can consist of three, four or five of the following

components. It can combine components of similar type of or different

types.

Component b

4-position component with flow rate regulation, double acting and

automatic return to neutral.

Component c

4-position component with flow rate regulation, double acting, zero leak

and automatic return to neutral.

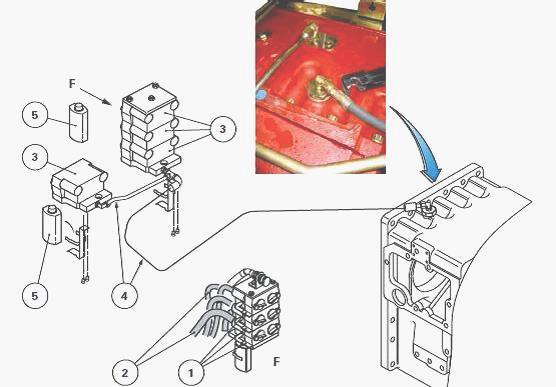

Couplers

The quick-disconnect couplings are held by a bracket on the centre

housing. They are sealed by covers of different colours (red, green,

black or yellow)

corresponding respectively to hydraulic ports A and B of auxiliary spool

valves.

When the auxiliary spool valve is at rest, a lever system (1) allows

existing pressure to be relieved into the hydraulic hoses (2). These

hoses link the spool valves

with the concerned couplers (3).

By acting on this system, the clean oil under pressure is directed to

the return via a hose and pipe assembly (4) connected to the upper part

of the intermediate

housing. This drop in pressure facilitates the connecting of the male

coupler to the female coupler.

The contaminated oil, coming from the separation of the couplers, flows

into flexible and transparent tanks (5) located on either side of the

third-point linkage.

Operation

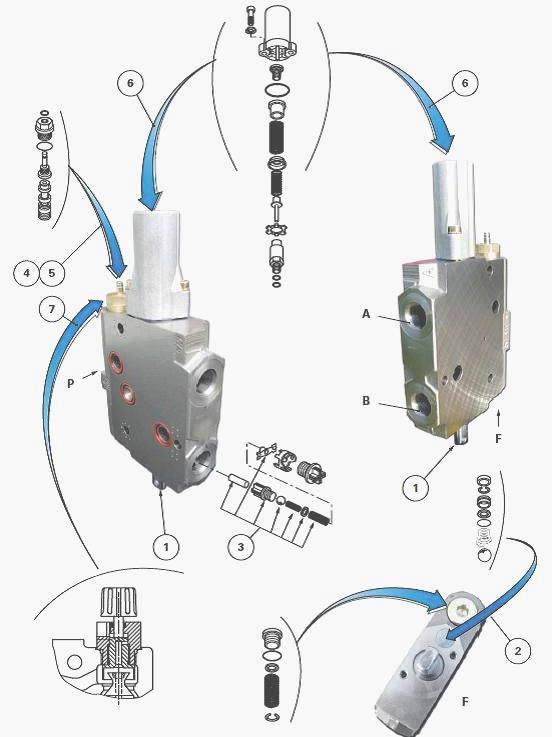

When the lever in the cab is pulled (spool (1) pushed), the oil enters

via channel P and travels towards the restrictor of the flow regulation

control spool (5) and

grooves of the main spool (1).

The oil is then carried towards a main channel and lifts the ball of

valve (2) to enter a chamber. Displacement of the spool (1)

simultaneously opens the one-way

valve (3).

The oil flows from the chamber towards port A and returns to the housing

through port B via the hydraulic slave device.

The operating principle is identical when the lever is pushed (spool (1)

pulled). The oil flows from the chamber towards port B and returns to

the housing through port

A via the hydraulic slave device.

Layout of components and identification of ports

(1) Main spool (2) Valve (3) Non-return valve (4) Flow regulation

control rod (5) Flow regulation control spool (6) Housing and locking

system (7) Flow regulation

control button

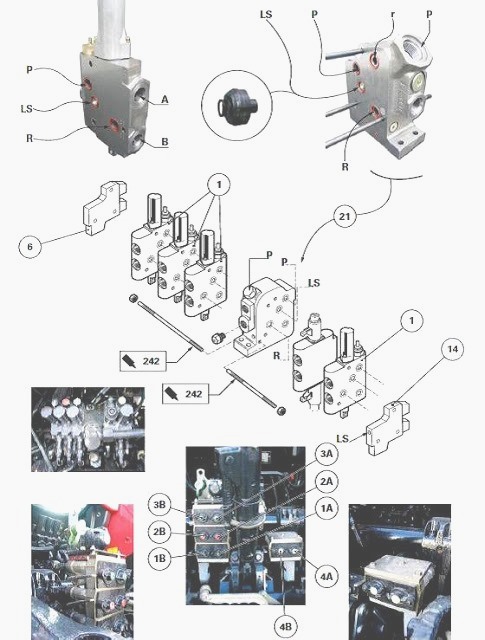

Removing and install the spool valve blocks

Disconnect the control cables (7) of each spool valve component by

uncoupling the sleeves (1) located under the cab.

Mark the position of the hydraulics hoses connected to the couplers.

Disconnect them from the MF 7499, 7495 spool valve block.

Disconnect:

- the high pressure pipe;

- the lift ram supply pipes;

- the LS hose.

Mark and disconnect the lift control valve solenoid valve harness (R10

Down - R11 Up).

Removal

Remove the screws and flanges from the manifold.

Sling the MF 7495, 7499 spool valve block.

Separate it from the support. Place it in a clean work area.

If necessary, remove support.

Discard the O'ring.

Reinstall

If it was necessary to remove the support, replace the return pipe

O’rings. Tighten the screws.

Clean the manifold mating face, along with that of the support.

If the studs need replacing, lightly smear the short thread of the new

studs with Loctite 270 or equivalent. Install and tighten the studs.

Clean off any excess Loctite.

Replace the O’ring.

Reinstall the spool valve block on the support.

Tighten:

- the screws to a torque of 50 - 70 Nm;

- the nuts to a torque of 90 - 120 Nm.

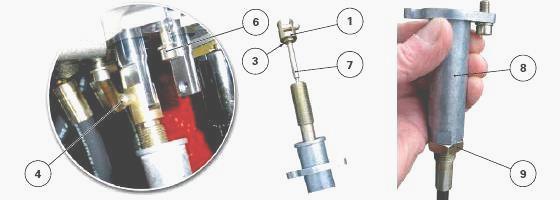

Assembling and adjusting a control cable

To be performed on the console

Remove right-hand console cover.

Install the unit (1) and its control cable on the suitable fixture.

Install the console cover.

To be performed on the Massey Ferguson 7499, 7495 auxiliary spool valve

Check, without turning, that the valve spool is in neutral position.

Screw clevis (1) flush with the threaded part of cable (7). Tighten nut

(3). Fit the pin (4).

Screw:

- the bell housing (8), partially;

- the screws (6) without tightening them.

Adjust the bell housing (8) by turning it from left to right to centre

the lever (1) in the console opening.

Lock the screws (6). Tighten the nut (9) to a torque of 20 Nm.

Check the operation of the spool valve control in all four positions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader