________________________________________________________________________________

Massey Ferguson 7495, 7499 hydraulic right-hand cover - Idler pinion and pump bearing block

Disassembling, reassembling and shimming of

the idler pinion

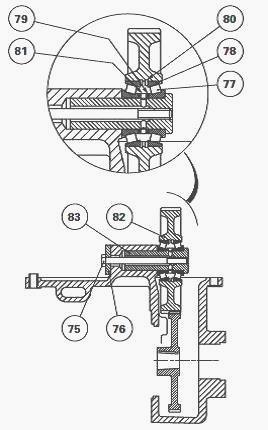

Disassembly

Remove the Massey Ferguson 7499, 7495 variable displacement pump.

Unlock and remove bolts (75). Take out pin (83) and pinion (82) and pair

together the bearing cones and cups (77) (78) if they are to be reused.

Recover the shim(s)

(79) and spacer (81). On the pinion, remove the bearing cups (78) and

circlips (80).

Reassembly

Place the bearing cups (78) thrust against the previously fitted

circlips.

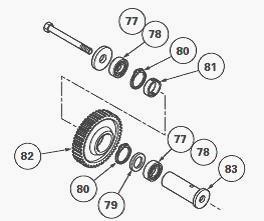

Reassemble the turning hub of the idler pinion (82) by assembling the

bearing cones (77), spacer (81), the shim(s) and pin (83).

If required, carry out the shimming of the idler pinion. Otherwise continue the reassembly operations. Assemble the pinion and pin on the cover.

Degrease the threads of bolt

(75) and lightly smear it with Loctite 241 or its equivalent. Fit washer

(76) and tighten the bolt

to a torque of 100 - 130 Nm. Manually check the rotation of the pinion.

Parts concerned by shimming

- The pinion (82), the circlips (80), the bearing cones and cups (77)

(78) and spacer (81).

- The clearance of the taper roller bearings is adjusted by shim(s) (79)

placed between the front cone (77) and spacer (81).

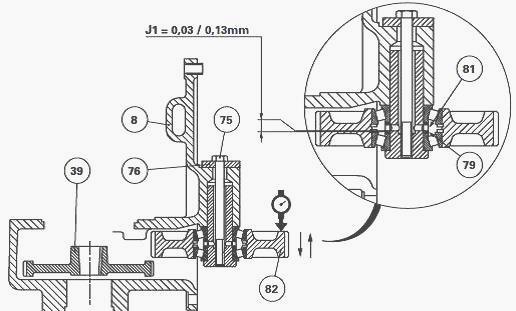

- To carry out the correct shimming of the bearings, place the cover in

a vice with the pump pinion (39) protruding as shown in Figure.

Shimming

Place the index of the dial gauge on the pinion (82). Push the pinion

strongly downwards, alternatively turning the pinion left and right in

order to correctly seat the

cone in the bearing cup.

Reset the dial gauge to zero. Repeat the operation, this time pulling on

the pinion instead of pushing. Depending on clearance measured, select a

thickness of shim

(s) in order to provide a clearance of: J1 = 0.03 to 0.13 mm.

Wherever possible, shim the bearings to the minimum clearance. Fit the definitive shim(s) selected in operation. Degrease the threads of bolt (75) and lightly smear the threads with Loctite 241 or its equivalent.

Fit washer (76) and tighten

the bolt to a torque of 100 -

130 Nm. Manually check the rotation of the pinion.

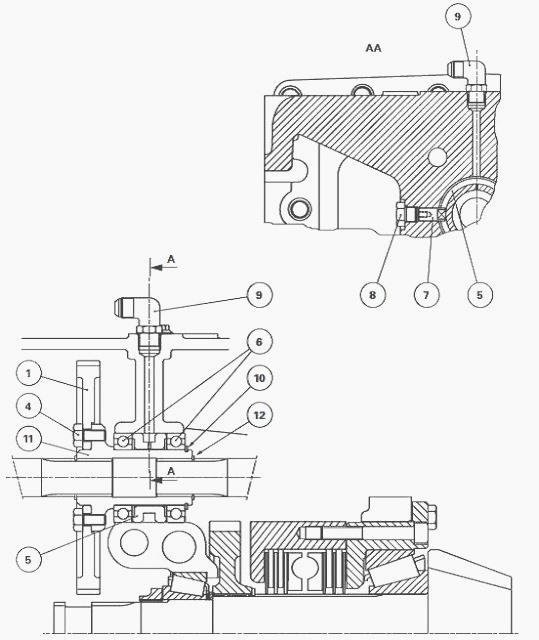

Removing and refitting – Disassembling and reassembling the pump bearing

block

- Place the rear wheels in the wide track position.

- Uncouple the MF 7495, 7499 tractor between the gearbox and the

intermediate housing.

- Remove the creeper unit components (if fitted).

- Free the ratchet of the Park Lock (if fitted). Take out the toothed

sleeve after carefully noting its position.

Removal

Immobilise pinions (1) (82) using a bronze drift. Take out bolts and

extract pinion. Take out plug (8).

Using a threaded rod screwed into the

threaded hole in locating

pin (7), pull on it so as to free spacer (5).

Through the front opening of the intermediate housing, pull on the

bearing block to disengage it from the bore of the housing.

Refitting

Check that the hydraulic channels and ports of the spacer are not

obstructed.

Refit the bearing block.

Carry out operation in reverse order. Place the

groove of the spacer in the axis of the port provided for the plug (8).

Fit the locating pin, with

the flats lodged in the groove in the spacer. Tighten the plug.

Check that the bearing block assembly is correctly positioned and that it turns normally.

Fit pinion (1). Tighten bolts (4) previously smeared

with Loctite 241 or its

equivalent to a torque of 72 - 96 Nm.

Disassembly

Remove the bearing block.

Take off circlip (10).

Extract bearings (6)

and recover spacer (5).

Reassembly

Clean and check the components. Replace any parts found to be defective.

Using a press and an appropriate fixture insert bearings (6), placing

spacer (5) between them.

Fit circlip (10). Check for the presence of circlip (12) on the upper

shaft of the power take off. Refit the bearing block and fit the pinion.

- The union (9) has a calibrated port for the lubrication of bearings

(6).

- If fitted, unclamp the ratchet and position the sleeve of the Park

Lock.

- The long part of the ratchet must face the drive pinion.

- Refit and adjust the creeper unit components (if fitted).

- Couple the MF 7495, 7499 tractor between the gearbox and the

intermediate housing.

- Replace the wheels in their initial positions. Tighten the wheel nuts

or studs.

- Check the operation of all the controls.

- Carry out a road test.

- Check the oil tightness of the mating faces and hydraulic unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader