________________________________________________________________________________

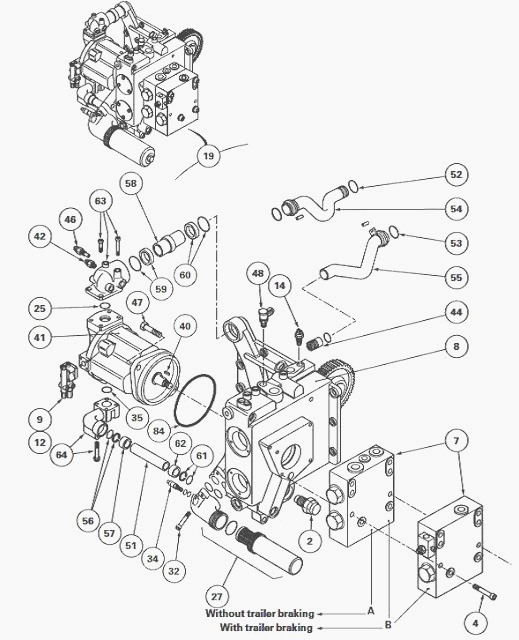

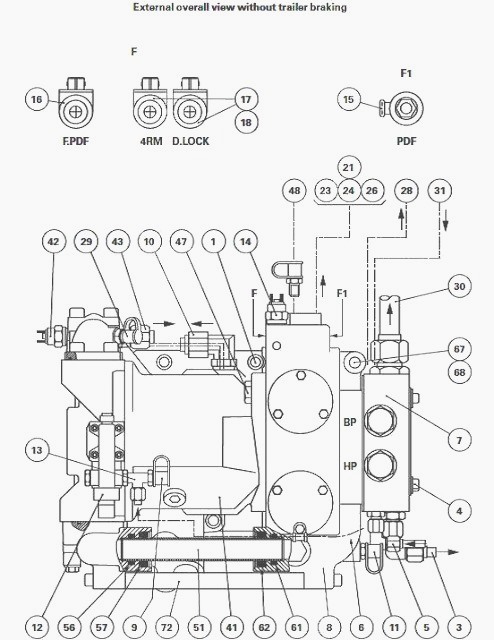

Massey Ferguson 7624, 7626 hydraulic system – right-hand cover

Massey Ferguson 7624, 7626 tractors may be fitted with a 150 l/min flowrate Load Sensing circuit.

The right-hand side hydraulic cover of this circuit is fitted on the intermediate housing as is the 110 l/min flowrate Load Sensing circuit.

The cover serves as a support for numerous components and contains

various channels for the booster, lubricating and low flowrate circuits.

On its internal face, the cover contains:

- an idler pinion (82) also known as the "relay" pinion.

- the safety valve (44) of the booster and lubricating circuit

calibrated at 5 bar.

- the safety valve (45) of the low pressure circuit (17 bar).

On its external face, the cover is fitted with:

- the variable displacement pump (41) and its regulator (12)

- the main 15 micron filter (27)

- one or two priority block(s) (7) (depending on assembly) serving the

various functions of the low and high flowrate circuits

- the high pressure relief-valve (2) calibrated at 230 bar

- the four solenoid valves (15) to (18) controlling the low pressure

functions (depending on options) one of which (power take off clutch) is

of the proportional type.

- the high and low pressure diagnostics connectors (11) (48), booster

(lubrication) (29) and Load Sensing (9).

- the low pressure (14) and booster (42) switches as well as the

clogging indicator (34) of the main filter (27).

MF 7624, 7626 Hydraulic routing

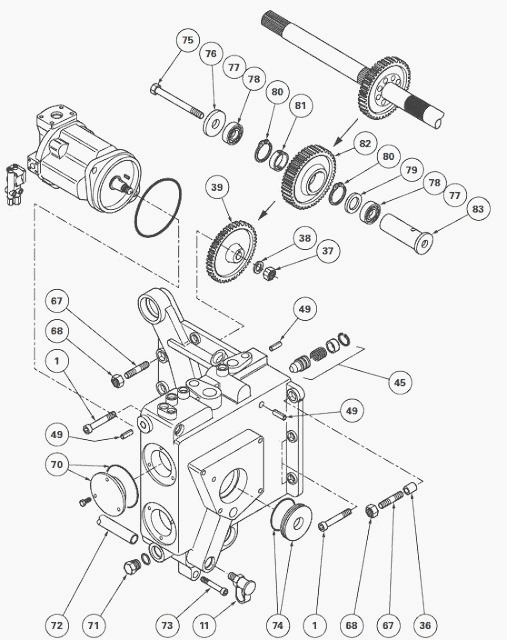

- The engine movement transmitted to pinion by shaft drives the variable

displacement pump pinion via the "relay" pinion (82).

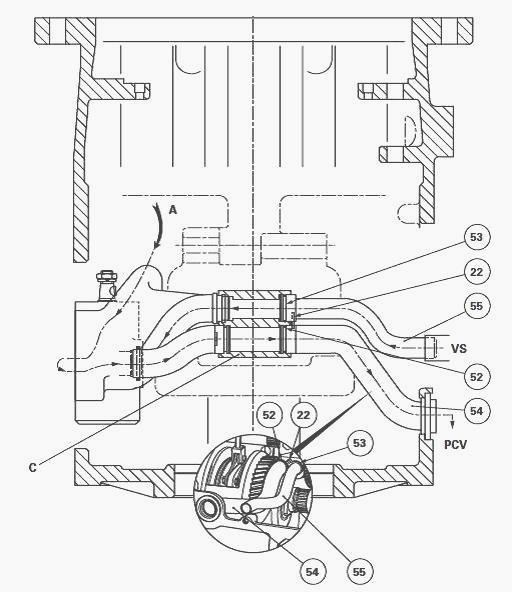

- The oil coming from the booster pump located on the left-hand cover

flows into the priority block(s) (7) (depending on version) via the main

filter (27) and the variable displacement pump (41).

- The tube (55) sends the oil coming from the 5 bar safety-valve into

the suction manifold of the booster pump when no hydraulic slave device

is used.

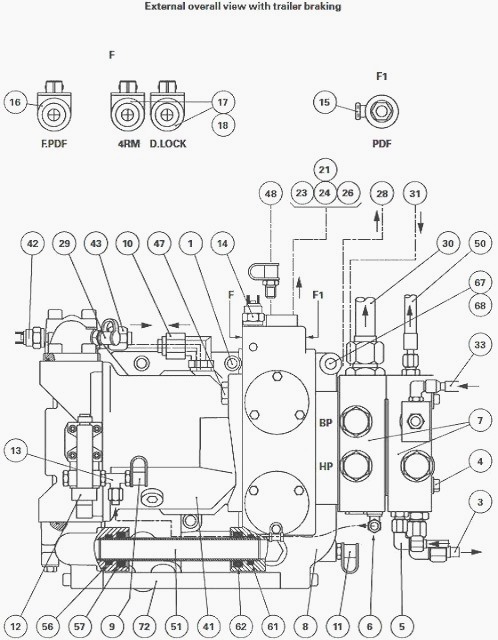

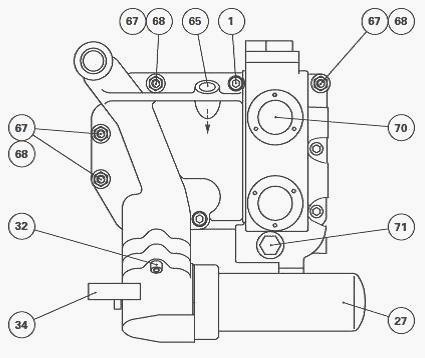

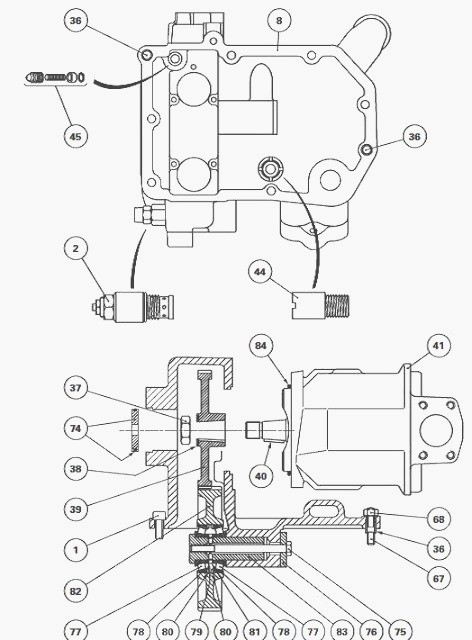

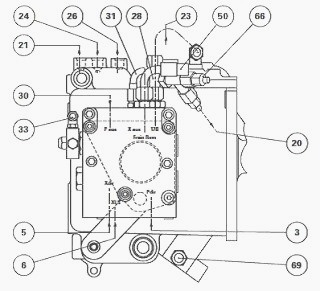

(1) Bolt (2) High pressure relief-valve (3) Orbitrol spool valve supply

port (4) Bolt (5) Load Sensing control port from Orbitrol spool valve

(6) Load Sensing control port to pump regulator (7) Priority block(s (8)

Cover (9) Load Sensing diagnostics connector (10) Return pipe (11) High

pressure diagnostic connector (12) Pump regulator (13) Load Sensing

union (14) Low pressure (17 bar) switch (15) Solenoid valves: power take

off, power take off to brake, differential lock front and rear if fitted

and

(18) 4WD (19) Hydraulic cover assembly (20) Park Lock union (21) Power

take off clutch port (22) Mecanindus pin (23) Power take off brake (24)

2WD or 4WD differential lock port (25) O’ring (26) Port for 4WD union

(27) 15 micron main filter (28) Low pressure port (29) Booster pressure

and lubricating diagnostic connector (30) Supply port for lift control

valve and auxiliary spool valves via the manifold (31) Load Sensing

control port from auxiliary spool valves and lift control valve (32)

Bolt

(33) Control port of trailer brake valve (34) Clogging indicator (35)

O’ring (36) Centring pins (37) Nut (38) Washer (39) Pump pinion (40) Key

(41) Variable displacement pump (42) Pressure switch (booster and

lubrication) (43) Port to lubricating manifold located above centre

housing (44) 5 bar safety valve

(45) 22 bar safety valve (46) Plug (47) Bolt (48) Low pressure

diagnostic connector (49) Rivets (50) Port to trailer braking quick

disconnect coupling (51) Transfer pipe (56) Composite seal (O’ring and

anti-extrusion bush) (57) Dust cover (58) Sleeve (59) O’ring and dust

cover (60) O’ring and dust cover

(61) Composite seal (O’ring and anti-extrusion bush) (62) Dust cover

(63) Suction manifold and bolt (64) Discharge manifold and bolt (65)

Lubricating port for relay pinion (66) Port to brake power assistance

(67) Studs (68) Nuts (69) Plug (70) Closing plate and seal (71) Plug

(72) Spacer (73) Bolt (74) Obturator and seal (75) Bolt (76) Washer (77)

Bearing cone (78) Bearing cup (79) Shim(s) (80) Circlips (81) Spacer

(82) Idler pinion (83) Pin (84) O’ring

(22) Mecanindus pin (52) O’ring (53) O’ring (54) Booster pipe (55)

Safety valve (44) pipe, A - Suction, PCV - To variable displacement pump

(41), VS - 5 bar safety valve (44), C - Intermediate housing compartment

Removing and refitting the cover

Immobilise the MF 7624, 7626 tractor. Chock the left rear wheel. Chock

between the frame and the front axle. Partially drain the intermediate

housing. Disassemble the right rear wheel. Position an axle stand.

Removing the priority block(s)

Proceed with the removal of the priority block(s) by removing bolts (4)

after previously disconnecting hose pipes (3) (5) (6) (28) (30) (31)

(50).

On Massey Ferguson 7624, 7626 tractors fitted with trailer braking,

remove the priority block(s) (7) without disconnecting hose (33).

This precaution will avoid bleeding of the valve pilot circuit when

refitting the cover.

Removing the cover

Disconnect pipes (10) (21) (23) (24) (26) (43), the solenoid valve

harnesses (15) to (18) (depending on the version) and switches (14) (34)

(42).

Take out bolts (32) and remove the main filter assembly (27). Remove

bolts (1) and nuts (68).

Check that there is no hydraulic or electrical link that remains

connected between the cover and the intermediate housing. Release and

remove the cover.

Certain nuts and bolts on the cover are difficult to access. Where

necessary, use a locally manufactured wrench. After removing the cover,

take out pipes (54) (55) (optional).

The 22 bar safety valve (45) comprises: circlip, stop, spring (3) and

valve.

Refitting the cover

Check for the presence of rivets (49) at the end of the channels located

on the external and internal faces of the cover. Clean the mating faces

of the housing and the cover.

Check for the presence of the two centring pins.

If removed:

- place seal (53) on pipe (55). Position the end of the pipe in the

Mecanindus pin (22) located on compartment "C" of the intermediate

housing.

- place seal (52) on pipe (54). Position the machined slot of the flange

in pin (1). Lightly smear the seal (4) with miscible grease and stick it

to the flange.

Check the location of the pins (67) in the intermediate housing.

The pins are first lightly smeared with Loctite 241 before fixing them

on the housing.

Smear the mating face of the housing with Loctite 510 or its equivalent.

With the assistance of another operator and the tool recommended in the preceding remark "Danger", refit the cover by aligning its holes with the studs on the housing.

Push the cover progressively while simultaneously checking between housing and cover mating faces that the 5 bar safety valve is correctly housed in pipe (55).

Tighten bolts (1)

and nuts (68) to a torque of 120 - 160 Nm.

If there is any resistance, stop tightening and open the gap between

housing and cover to check on the correct alignment of pipe (55) and the

5 bar valve.

Refit the main filter assembly (27) and tighten bolts (32). Reconnect

the harnesses to the solenoid valves and switches. Carry out operation

in reverse order.

Refitting the priority block(s)

Refit the priority block(s) and check for the presence of seals. Tighten

bolts previously smeared with Loctite 542 to a torque of 25 - 35 Nm.

Reconnect the pipes or hoses. Carry out operation in reverse order.

Refit the rear wheel. Remove the axle stand. Tighten the wheel nuts or

studs (depending on version). Top up the oil levels in the housings and

check the transparent tube on the left-hand side of the centre housing.

Remove the chocks.

Start the engine and check:

- the operation of the hydraulic and electrical components

- the oil tightness of the mating faces, pipes and hoses.

- If the variable displacement pump has been replaced, carry out

hydraulic tests. Carry out a road test.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader