________________________________________________________________________________

Massey Ferguson 7614, 7615 robotic mechanical gearbox

The GBA25 gearbox is equipped to Massey Ferguson 7614, 7615 tractors

with Dyna 4 transmission. This transmission is fully automated. It

allows shifting between all the ratios without declutching.

The gearbox is divided into two parts:

- The Powershift module, with four ratios for shifting under load.

- The robotically-controlled mechanical gearbox with four ranges.

MF 7614, 7615 transmission assembly is controlled electronically by an

Autotronic 5 calculator. The GBA25 Dyna-4 gearbox has 16 ratios.

These

are provided by 4

Powershift module ratios for shifting under load, and 4 mechanical

gearbox ranges. The mechanical gearbox ranges are controlled like a

ratio for shifting under load.

The ratios are controlled by two levers:

- Power control lever located under the steering wheel.

- gear shift lever located on the armrest.

The mechanical gearbox is located between the Powershift module and the

rear axle. It comprises two shafts (upper and lower shaft lines), on

which four gear trains

with helical teeth rotate.

Input drive is supplied by the Power Shuttle

and is transmitted to the upper shaft line. Output drive is transmitted

via the lower shaft line to a

creeper unit or directly to the crown wheel and pinion.

The lubricating oil coming from the 5 bar valve of the MF 7615, 7614

tractor is sent to the gearbox lower shaft line and upper shaft line. A

network of internal

channels directs the oil to the elements requiring lubrication.

Selecting ratios

Ratios are selected using two synchronisers, one single cone and one

double cone. Each synchroniser is engaged individually.

The synchronisers are controlled by two selector rails and two forks. Each selector rail has a double-acting piston, allowing range shifting.

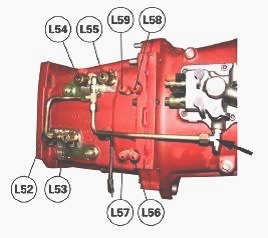

The selector rail pistons are controlled hydraulically via the Massey Ferguson 7614, 7615 tractor 20 bar circuit. Four solenoid valves (L52, L53, L54, L55) located on the right-hand side of the gearbox control selector rail movement.

Four switches (L56, L57, L58, L59) inform the calculator of

the selector rail positions. The switches are pressed in by pins (130).

Each range has a

corresponding solenoid valve and switch.

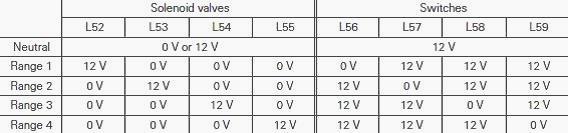

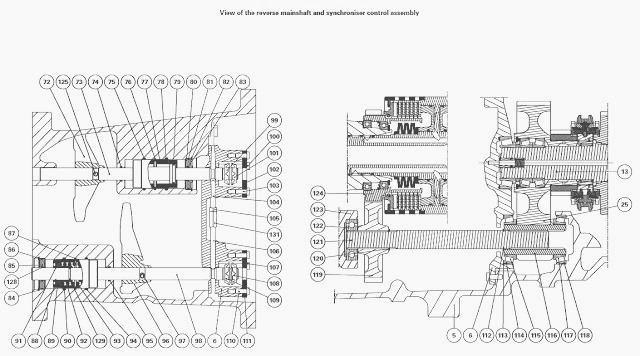

(1) Primary shaft (2) Bearing cone (3) Bearing cup (4) Shims (5) Gearbox

housing (6) Cover (7) Shims (8) Bearing cup (9) Bearing cone (10) "O"

ring (11) Spring

(12) Lubrication pipe (13) Secondary shaft

(14) Spacer (15) Circlip (16) Washer (17) Shims (18) Circlip (19) Washer

(20) Shims (21) Bearing cup (22) Bearing cone (23) Bearing cone (24)

Bearing cup (25)

Pinion (26) Double pinion (27) Bearing cup (28) Bearing cone (29)

Bearing cone (30) Bearing cup (31) Pinion (32) Needle bearing (33)

Washer

(34) Circlip (35) Circlip (36) Spacer (37) Needle bearing (38) Needle

bearing (39) Spacer (40) Circlip (41) Shims (42) Circlip (43) Pinion

(44) Spacer (45) Pinion (46)

Bearing cone (47) Bearing cup (48) Pinion

(49) Ring (50) Bearing cone (51) Bearing cup (52) Deflector (53) Ring

(54) Sliding coupler (55) Ball bearing (56) Pressure connector (57)

Brake (58) Spring (59)

Flange (60) Hub (61) Ball bearing (62) Pressure connector (63) Ring (64)

Spring (65) Brake (66) Cone (67) Flange (68) Snap ring (69) Hub

(70) Sliding coupler (71) Power take-off shaft (72) Fork (73) Selector

rail (74) "O" ring (75) "O" ring (76) Circlip (77) Sleeve (78) "O" ring

(79) "O" ring (80) Plug (81)

"O" ring (82) Circlip (83) "O" ring (84) Circlip (85) Plug (86) "O" ring

(87) Circlip (88) Sleeve (89) "O" ring (90) "O" ring (91) Snap ring

(92) Piston (93) Spring (94) "O" ring (95) "O" ring (96) Fork (97) Pin

(98) Selector rail (99) Castellated nut (100) Screws (101) Castellated

nut (102) Plate (103)

Screws (104) Rail (105) Locknut (106) Rail

(107) Screws (108) Castellated nut (109) Castellated nut (110) Screws

(111) Plate (112) Circlip (113) Shims (114) Bearing cup (115) Bearing

cone (116) Pinion

(117) Bearing cone (118) Bearing cup (119) Pinion (120) Circlip (121)

Shaft (122) Bearing (123) Powershift module cover (124) Reverse pinion

hub (125) Pin (126)

Plug (127) Plug (128) "O" ring (129) "O" ring (130) Pin (131) Reverse

pitch nut

Description and kinematics of ratios

The MF 7614, 7615 robotic gearbox allows four ratios to be obtained with

only four gear trains, two shafts and two synchronisers.

Kinematics

Range 1 - The reduction is carried out on three gear trains. The first gear train

drives the second train via the 1st gear synchronisers, then the third

train.

Range 2 -

The reduction is carried out on the first gear train. The 2nd gear

synchronisers secure the 2nd gear pinion to the secondary shaft.

Range 3 -

The reduction is carried out on the third gear train. The primary shaft

is secured to the 3rd gear pinion by the 3rd gear synchronisers.

Range 4 - The reduction is carried out on the fourth gear train. The primary shaft

is secured to the 4th gear pinion by the 4th gear synchronisers.

In forward position, input drive comes directly from the Power Shuttle

to the primary shaft (1). In reverse position, drive comes from the

Power Shuttle via the

pinions (124), (119) and (116) and the shaft (121). It enters via the

second driven pinion (25), which is constantly meshed to the primary

shaft (1).

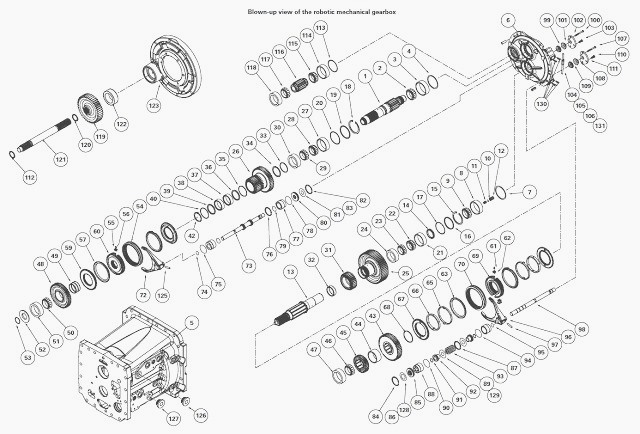

Primary shaft

The primary shaft (1) is splined to the Power Shuttle forward hub. It is

supported by two taper roller bearings (3)(4) and (50)(51) Adjustment is

controlled by shims

(4).

The PTO shaft (71) is inserted through the centre of the primary

shaft (1). This cavity in the shaft (1) also serves as a channel for

lubricating oil.

The first and second driving gear is cut into the primary shaft (1). The double pinion (26) turns idle on the shaft (1) and is supported by two taper roller bearings (27) (28) and (29)(30) and two needle bearings (37)(38).

This pinion is

supported on the shaft by shims (20). The fourth driving gear turns idle

on the shaft (1). It is

supported by a lubricated bush (49).

Secondary shaft

The secondary shaft (13) turns on two taper roller bearings (8)(9) and

(46)(47). Bores in the centre of the shaft (13) ensure proper

lubrication.

Adjustment is

controlled by shims (7). The pinion (25) turns truly on the shaft (13)

and is supported by two taper roller bearings (21)(22) and (23)(24) and

a needle bearing (32).

The pinion (25) acts as a bearing to the idle pinion (31). This pinion

(31) is in direct contact with the pinion (25). A layer of oil ensures

the mating faces are lubricated.

The pinions (43) and (45) are splined to the shaft (13). They are

separated by a spacer (44).

Synchronisers

The single cone synchroniser located on the primary shaft (1) allows

shifting between the third and fourth gears. Its hub (60) is splined to

the shaft (1). It is held in

position by a circlip (42) on one side and by the bearing cone (50)

fitted tightly on the shaft (1).

By moving the slider (54), the shaft (1) is locked either:

- with the double pinion (26) (3rd)

- with the pinion (48) (4th).

The double cone synchroniser located on the secondary shaft (13) allows

shifting between the first and second gears. Its hub (69) is integral

with the pinion (25). It is

held in position by the snap ring (68).

By moving the slider (70), the shaft (13) is locked either:

- with the idle pinion (31) (1st)

- or with the pinion (43) (2nd).

Selecting ratios

The synchronisers are controlled conventionally by forks (72) and (96)

and selector rails (73) and (98). The selector rails are controlled

hydraulically. The selector

rails are controlled by double-acting pistons.

On the selector rail (98) that controls the 1st and 2nd gear

synchroniser, the piston (92) is damped by a spring (93) to give smooth

shifting between ranges 1 and 2.

The selector rails are adjusted by tightening or loosening the castellated nuts (99)(101) and (108)(109). Once adjusted, the stops are held in position by screws (100) and (107).

An interlock mechanism comprising two rods (104)(106) and a locknut (105) prevents the selector rails from being engaged simultaneously. When one selector rail is engaged, the pin locks the other rail in a groove.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader