________________________________________________________________________________

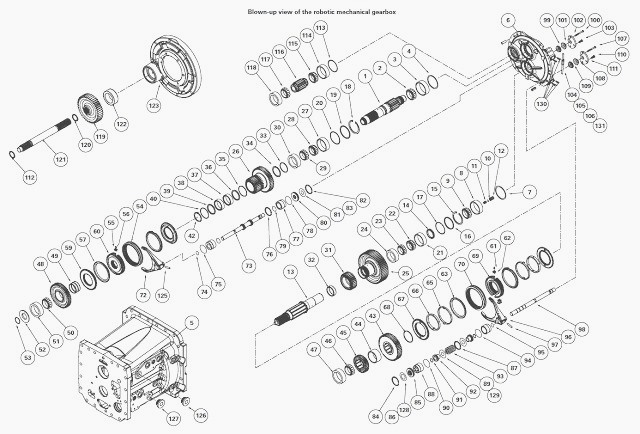

Massey Ferguson 7614, 7615 robotic mechanical gearbox - Primary and secondary shafts

Drain the transmission oil. Split the MF 7614, 7615 tractor in order to

remove only the robotic gearbox (if servicing only concerns the robotic

gearbox) or the complete Dyna-4 unit (then split the two housings).

Remove:

- all hydraulic pipes fitted to the unit housing

- the PTO shaft.

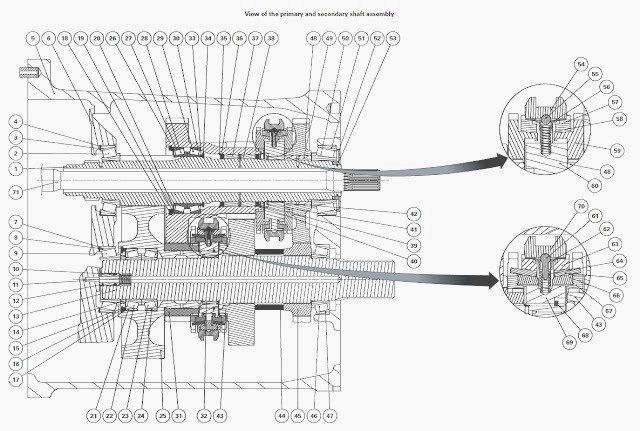

Removing the primary and secondary shafts

Rig up four makeshift legs on which to set the unit vertically.

Use an

M14 screw or threaded rod, and weld on a nut to ensure a minimum

distance of 120 mm

between the unit and the work surface.

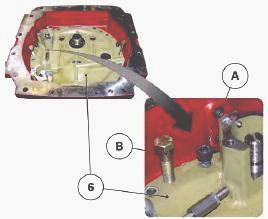

Position the unit on the legs, with the cover (6) on top.

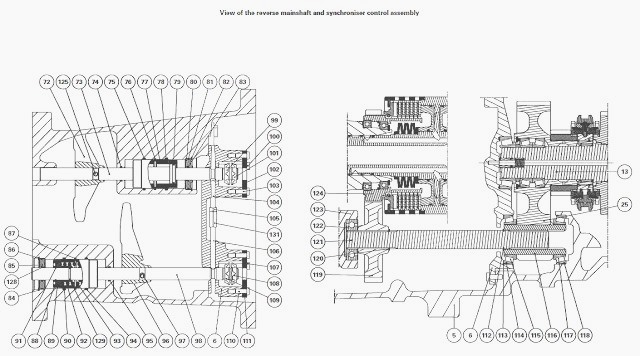

Take off the covers (102) and (111). Unscrew the castellated nuts

(99)(101) and (108)(109). Retighten the safety finger rod (106) to its

maximum.

Remove the two plugs (126) and (127). Drive out the two pins (97) and (125) holding the forks on the selector rails. The pins will fall into the gearbox housing.

They

must be recovered when the Massey Ferguson 7614, 7615 gearbox is

disassembled.

Remove the circlip at the rear of the gearbox (84).

Using a plastic hammer, remove the selector rail (98) towards the rear of the gearbox. The rail control piston assembly is fitted to the rail and is removed with it.

Part

of the sleeve remains in the cylinder. If it must be removed, take off

the circlip (87) and extract the sleeve. Remove the screws (A) from the

cover (6).

Install two screws (B) in the threaded holes in order to lift up the

cover (6).

Remove the cover (6). Recover the bearing cups (3), (8) and (114) and

the shims (4), (7) and (113).

Recover the lubricating pipe (12), the seal (10) and the spring (11). Remove the circlip (82). Using a plastic hammer, remove the selector rail (73) towards the front of the gearbox.

The rail control piston assembly is fitted to the rail

and is removed with it.

Part of the sleeve remains in the cylinder. If it must be removed, take

off the circlip (76) and extract the sleeve.

Disassembling and reassembling the selector rail (ranges 1 and 2)

Clamp the rail (98) in a vice equipped with protective jaws.

Tighten the two pistons (92) in the vice to compress the spring.

Remove a snap ring (91). Remove the pistons (92) and the spring (93).

Replace the seals (129) on the rail (98).

Carry out operations in reverse order to assemble the selector rail.

Turn the forks (72) and (96) inwards in the MF 7615, 7614 tractor

gearbox to allow them to enter the housing.

Place service tool in the primary and secondary shafts.

Sling the tool using a pulley hoist or a suitable lifting system. Extract the two shafts (1) and (13) from the gearbox housing. Take care when the 1st/2nd gear synchronizer is passing beside the reverse shaft support.

The total

weight of the two shafts is approximately 44 kg (lower shaft line = 27

kg, upper shaft line = 17

kg).

Remove the assembly and place it on a workbench.

Remove the service tool

and split the two shafts. If required, extract the bearing cups (47),

(51) and (118) from

the gearbox housing. If necessary, remove deflector (52).

Reinstall the primary and secondary shafts

Ensure all parts are clean and in good condition. Check that the

lubricating ports and range control ports are clean.

Replace all the "O" rings, greasing them lightly before assembly.

Do not

forget to replace the "O" rings (74), (75), (78), (90), (94) and (95) in

the selector rail bores

inside the housing. Check the presence of the bearing cups (47), (51)

and (118) in the housing (5).

Assemble the shafts (1) and (13).

Install the forks (72) and (96) on the synchronizer sliders. The offset

side of the fork must be turned towards the front of the Massey Ferguson

7615, 7614 tractor.

The two forks are identical. They have the same reference. Install the two shafts in the housing. At the same time, Install the reverse transfer pinion (116) fitted with the two bearing cones (115) and (117).

Ensure the pinion

(116) is positioned correctly. The marks on the teeth should be turned

towards the bottom of the housing.

Reinstall the lubricating pipe (12) fitted with a new "O" ring (10) and

the spring (11).

If the sleeve (77) and the circlip (76) have been removed, grease the sleeve, insert it into the cylinder, then fit the circlip (77). Thread the selector rail (73) with the lightly greased piston assembly into its housing.

To help insert the selector rail into the fork, use a

pin punch to hold the fork in

place. Install the plug (80) fitted with two new "O" rings (81) (83).

Install the circlip (82).

If the sleeve (88) and circlip (87) have been removed, grease the sleeve, insert it into the cylinder, then fit the circlip (87). Thread the selector rail (98) with the lightly greased piston assembly into its housing.

To help insert the selector rail into the fork, use a pin punch to hold the fork in place. Mount the plug (85) fitted with two new "O" rings (86) (128). Install the circlip (84).

Align the holes in the forks (72) and (96)

with those in the corresponding

selector rails.

Insert new pins to attach the forks to the selector rails. Install the

plugs (126) and (127).

Check the interlock mechanism is in position and retighten the rods

(104) and (106) to their maximum tightness.

Install the four switch thrust pins (130) using a bit of grease to hold

them in position. In the cover (6), Install the bearing cones (3), (8)

and (114) smeared with grease

to hold them in position.

Also Install:

- the original thickness of shims if the roller bearings have not been

replaced

- the calculated thickness of shims if the roller bearings have been

replaced.

Put the cover back on (6). Install the cover (6) screws smeared with

Loctite 242. Tighten to a torque of 57–77 Nm.

Reinstall the ring (52) with the lubricating port turned towards the top

of the gearbox. Fix it in position with four punchmarks.

Adjust the selector rails and forks. Adjust the interlock mechanism.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader