________________________________________________________________________________

Massey Ferguson 7720, 7726, 7480, 7495 Dyna VT transmission PTO

Disassembling the Dyna VT transmission power

take-off

Lower the rear linkage. Drain the transmission oil. Remove the trailer

linkage (depending on equipment). Mark and remove the PTO connector TR9.

Mark and remove the PTO connector TR10. Unscrew all attachment screws.

Take the silicone out of the threaded bores and tighten 2 screws M12

Support the cover using a lifting tool and push it back using the two

screws.

Take off the Massey Ferguson 7480, 7495 rear PTO transmission cover.

Take care of the adjustment shims, which are used to adjust the bearing

clearance.

Push back the clutch cover (3) using 2 disc screws M10.

Remove the nozzle (29). Fit the compression tool and

compress the clutch. Extract the locking half-rings (30).

Release the clutch. Remove the disc carrier and the set of discs (10).

Remove the adjustment shims (8), the set of Belleville washers (9) and

the ring (14). Remove the piston (13). Remove a screws (21) and take off

the blade (18).

Take off the circlip (31) and remove the brake disc

(20). Take off the brake disc. Extract the bearing (101) using an

extractor. Take out the washer. Unscrew the nuts (210 and 211). Note the

values of the nuts (210 and 211) if required. Remove the stops (116).

Take out the control mechanism. Remove the pinions (118) and (118a).

Take out the shaft (35). If required, take off the external rings of the

bearing. If necessary, remove the ram (217) and or (226). Take off the

circlip (107), washer (108) and pinions. Remove the circlip (112).

Release the pinion (118).

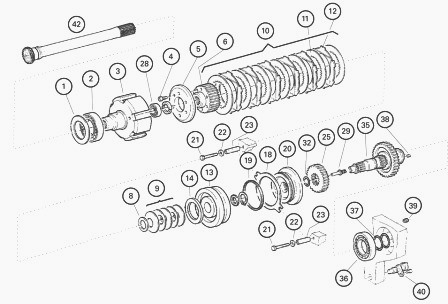

Massey Ferguson 7720, 7726 Power take-off clutch

1 - Shim, 2 - Taper roller bearings, 3 - Clutch cover, 4 - Cylindrical

screw, 5 - Shim, 6 - Internal blade holder, 8 - Shim, 9 - Spring washer,

10 - Set of blades, 11 - Disc, 12 - Intermediate plate, 13 - Piston, 14

- Ring, 16 - Lip seal, 18 - Plate, 19 - Lip seal, 20 - Brake disc, 21 -

Allen screw, 22 - Grower washer, 23 - Bush, 25 - Pinion, 28 - Taper

roller bearing, 29 - Nozzle, 30 - Locking half-rings, 31 - Circlip, 32 -

O’ring, 35 - Shaft, 36 - Taper roller bearing, 37 - Ring with

rectangular section, 38 - Grub screw, 39 - Nozzle, 40 - Sensor, 42 -

Shaft

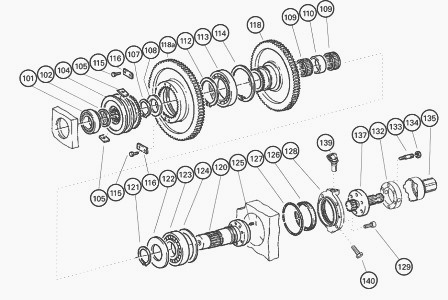

MF 7720, 7726, 7480, 7495 Rear PTO drive

101 - Taper roller bearing, 102 - Shim, 104 - Clutch body, 105 - Roller,

107 - Circlip, 108 - Washer, 109 - Needle bearing cage, 110 - Spacer,

112 - Circlip, 113 - Taper roller bearing, 114 - Circlip, 115 - Allen

screw, 116 - Stop, 118 - Pinion (1000 rpm), 118A - Pinion (540 or 750

rpm), 120 - Shaft, 121 - Circlip, 122 - Washer, 123 - Taper roller

bearing, 124 - Shim, 125 - Grub screw, 126 - Spi seal, 127 - O’ring, 128

- Bearing cover, 129 - Cylindrical screw, 132 - Spacer, 133 - Threaded

stud M10 x 50 - 10.9, 134 - Nut M10-10, 135 - PTO guard, 137 -

End-fitting, 139 - Sensor, 140 - Allen screw

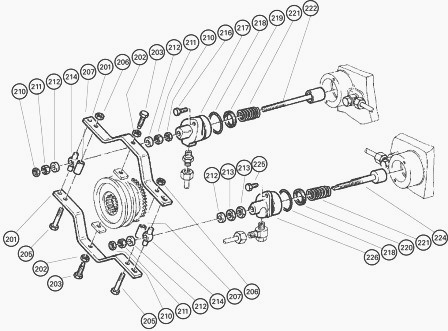

MF 7720, 7726 Rear PTO control

201 - Stirrup, 202 - Hexagonal nut, 203 - Stud, 205 - Allen screw, 206 -

Hexagonal nut, 207 - Spacer pipe, 210 - Hexagonal nut, 211 - Hexagonal

nut, 212 - Washer, 213 - Hexagonal nut, 214 - Roller, 216 - Allen screw,

217 - Rams, 218 - O’ring, 219 - Compact seal, 220 - Compact seal, 221 -

Spring, 222 - Piston, 224 - Piston, 225 - Allen screw, 226 - Rams

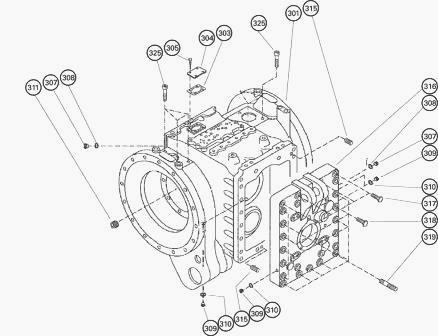

Rear Power take-off cover

301 - Rear axle housing, 303 - Seal, 304 - Cover, 305 - Allen screw, 307

- Closing plug, 308 - Sealing ring, 309 - Closing plug, 310 - Sealing

ring, 311 - Closing plug, 315 - Dowel pin, 316 - Housing cover, 317 -

Screw M18 x 90 - 10.9, 318 - Screw M18 x 110 -10.9, 319 - Threaded stud

M18 x 130 - 10.9, 322 - Sealing ring, 325 - Cylindrical screw

Disassembling Massey Ferguson 7720, 7726 Dyna VT transmission power

take-off

Fit home the bearing (113) in the pinion (118a) and lock with the

circlip (114), then fit the pinion (118) to its stop. Fit the circlip

(112) on the opposite side.

Fit home the internal ring of the bearing (123) on the shaft (120). Position the washer (122). Fit the circlip (121). Smear the 2 grub screws (25) with plastic binder and tighten them until the internal ring of the bearing (123) reaches its stop.

The washer (122) must be fitted

home. Fit the 1st needle bearing cage (109), the spacer (110) and the

2nd needle bearing cage (109) on the shaft (120). Fit the shaft (120).

Position the washer (108). Fit the circlip (107). Fit new seals (219) in

the ram (217).

Fit a new O’ring (218) in the groove of the ram (217). Smear the oil tight seals with miscible grease. Insert the piston (222) and spring (221) as indicated in the ram (217).

The oil tight seal (219) is

comprised of 2 parts: an O’ring on the outside and a piston strip guide

on the inside.

Fit new seals (220) in the ram (226). Fit a new O’ring (218) in the

groove of the ram (226). Smear the oil tight seals with miscible grease.

Insert the piston (224) and spring (221) as indicated in the ram (226).

The oil tight seal (219) is comprised of 2 parts: an O’ring on the

outside and a piston strip guide on the inside. Fit the rams (217 and

226). Smear the thread of the screws (216 and 225) with plastic binder

and tighten the

screws to the following torque: 49 Nm

Refit the hydraulic pipes which have been removed in the housing cover

(316).

If the housing is fitted with a new cover (316), screw the nozzle (29)

to its stop in the threaded bore. Fit home the external ring of the

bearing (36).

Smear 2 new rings (37) with miscible grease and install and lock them in

the grooves of the shaft (35). Fit home the internal ring of the bearing

(36).

When assembling a new shaft (35), smear the thread of the threaded stud (38) with plastic binder, and screw to its stop. Tighten the nozzle (29) to its stop. Fit the pre-assembled shaft (35) in the housing cover (316).

If required, fit compensating shims (124) and fit home the

external ring of the bearing (123). Fit the pair of ring gears and the

pinion (25).

Pre-assembling the stirrup

Smear the thread of the screws (205) with plastic binder.

Fit spacers (207) and rollers (214). Tighten nuts (206). Insert the

rollers (105) into the clutch body (104). Smear the thread of the screws

(203) with plastic binder. Fit the stirrup tight to an identical

distance, then loosen each screw (203) by 1/6 of a turn and lock them in

this position.

Screw the nuts (ref. 210, 211 and 213) onto the rods of the pistons (222, 224). Fit the washers (212) with their chamfer turned upwards. Fit the pre-assembled stirrup (201). Fit the washers (212) with their chamfer turned downwards. Unscrew the nuts (210 and 211). Smear the thread of the screws (115) with plastic binder.

Fit the stops (116) and

lock the screws (115). The following must be carried out before setting

stirrup travel:

The oblong hole in the stirrup (201) must be turned towards the ram

(226).

Screw and lock the nuts (211, 210) to their stop. Screw a locally made

eye nut M12 onto the piston rod of the ram (217).

Using a lifting tool, pull hard on the piston rod. (Coupling at 750 or 540 rpm). Check the clearance of the clutch body (104). Specified value: 0.1 to 0.2 mm clearance. If outside the specified clearance: Adjust with nuts M12 (top and bottom) until clearance of 0.1 to 0.2 mm is obtained.

Take off the lifting tool and unscrew the eye nut M12.

Push the piston rod of the ram (226) fully in using a clamp, until the

nuts (213) and at their stop. (Lifting limit, 1000 rpm position).

Check the clearance of the clutch body (104). Specified value: 0.1 to

0.2 mm clearance. If outside the specified clearance:

Adjust the nuts (213) until clearance of 0.1 to 0.2 mm is obtained.

Take off the clamp. The coupling shifts to "Neutral" position. The 750 or 540 and 1000 rpm ring gears should be able to turn freely. The upward and downward free travel of the coupling should be identical. If not, readjust the coupling. Fit the shim (102). Fit the internal ring of the bearing (101) up against the shaft (120).

Fit the pinion (25). Smear a new O’ring with miscible grease and fit it in the groove of the shaft (35). Check the brake disc (20) for wear. If necessary, fit a new brake disc (20). Fit the circlip (31). Smear a new lip seal (19) with miscible grease and fit it in the brake disc groove, with the seal lips turned towards the oil chamber.

Fit the blade (18). Smear the thread of the screw (21) with Loctite, and fit the Grower washer (22) and socket (23). Tighten the screw. Smear a new lip seal (16) with miscible grease and fit it in the inner groove of the piston, with the seal lips turned towards the oil chamber. Fit the pre-assembled piston (13). Fit the ring (14).

Fit 5 Belleville

washers (9) with the large external diameters facing each other, and the

compensating shims (8). The external diameter of the first Belleville

washer (9) should be turned towards the ring (14) of the piston (13). If

required, for example if compensating shims (8) are lost, set the

preload of the Belleville washer set (9).

Setting the preload of Belleville washer set

Remove the shim (5) from the internal disc carrier (6).

Smear the thread of the screw (4) with plastic binder and tighten. Fit

home the pre-assembled ring carrier (6).

Measure and note the distance between the disc carrier (6) and the end

of the shaft (35). Example: 23.2 mm.

Fit the compression tool and compress the set of Belleville washers (9).

Fit the locking half-rings (30).

If the locking half-rings (30) are chamfered on just one side, the chamfered side must face the disc carrier (6). Remove the compression tool.

Measure and note the distance between the disc carrier (6) and the end of the shaft (35). Example: 25.8 mm. If the washer set gives compensating clearance of approximately 2.5 mm when completely compressed, the preload is correct. If not, correct it with compensating shims.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader