________________________________________________________________________________

Massey Ferguson 7715, 7718 Load sending and twin flow load sending - Lift control spool valve

The function of the MF 7715, 7718 lift control valve is to regulate the oil flow to and from the lift rams according to the signals transmitted by the ELC calculator.

The lift control valve contains an LS port for the Load Sensing system. This pilot port allows the valve to send pressure data to the regulator via the priority block(s).

This lift control valve is made up of elements themselves comprising

spools and valves. Some of the elements cannot be repaired as spare

parts.

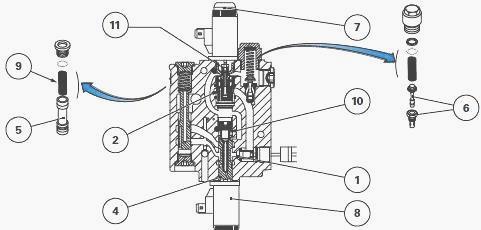

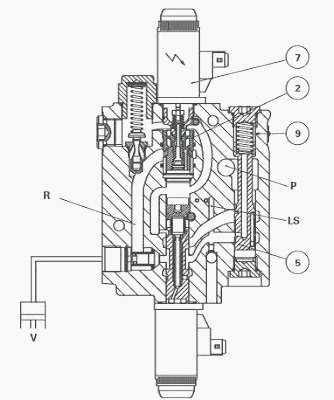

Layout of components and identification of ports

The Bosch/Rexroth lift control valve consists of two parts: Hydraulic

part (spool valve) and Electrical part (solenoid valves).

Hydraulic part (spool valve) - (1) Non-return valve, maintaining the oil

in the rams (2) Spool valve assembly used in the lowering phase (4)

Control spool valve (5) Flow regulating spool valve (6) Shock valve (9)

Flow regulating spool spring (10) Control spool spring (11) Spool valve

assembly spring, Electrical part (solenoid valves) - (7) Lowering

solenoid valve (8) Lifting solenoid valve

In order to determine whether the fault is of hydraulic or electric

type, press the push-buttons at the ends of the solenoid valves; this

eliminates the electronic effect of the lift function.

Identification of ports (GPA20 and GPA40

rear axles)

On the inlet block

HP supply from the two-cylinder pump via the priority block(s)

(depending on model)

LS signal to the balance block via the priority block(s)

On the lift control valve

Rams return pipe or hose to housing

HP ram supply

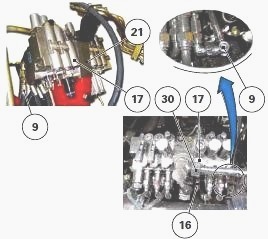

Identification of ports (GPA30 rear axle)

On the right-hand end plate - (9) LS hose from the priority block(s)

On the oil manifold (21) - (30) High pressure hose from the priority

block(s)

On the lift control valve (17) - (16) Lift ram supply pipes

Removing - install the spool valve block and the lift control valve

(GPA30 rear axle)

Removing the Massey Ferguson 7715, 7718 auxiliary spool valves

Remove the complete auxiliary spool valve block/lift control valve in

order to reach the lift control valve under optimum conditions of

cleanliness.

Install the spool valve block.

Reinstall the complete auxiliary spool valve block/lift control valve.

If necessary, carry out the hydraulic tests related to the operations

performed.

Disassembling and Reassembling the MF 7715, 7718 lift control valve

Carefully clean the complete auxiliary spool valve block/lift control

valve before carrying out servicing.

Split the components of the auxiliary spool valve block down to the lift

control valve.

Reassemble the complete auxiliary spool valve block/lift control valve.

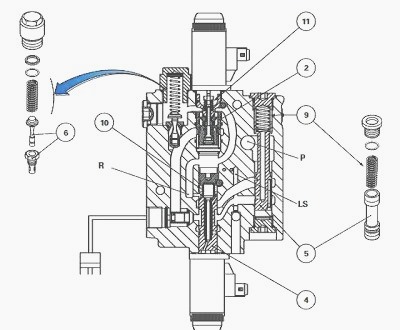

Neutral position

When the Massey Ferguson 7715, 7718 tractor engine is not running and

the spool valve is in the neutral position, the control spool (4) and

the spool valve assembly (2) are maintained respectively by the springs

(10) and (11).

The flow rate adjustment spool (5) is pushed downwards by

spring (9). When the engine is running and the spool valve is at rest,

no pressure information is transmitted to the variable displacement

pump. The LS line communicates with the return.

Up position

When the Move Up solenoid valve (8) is activated, the control spool (4)

is moved upwards. The LS pressure information acting on the upper face

of the flow rate regulating spool (5) (spring (9) side) moves the spool

downwards thus directing the flow to the control spool and the

non-return valve (1).

The movement of the flow regulating spool valve is dampened by the volume of oil present in chamber D. As soon as the pressure on the valve (1) is greater than that in the rams, the lifting arms rise.

The LS line communicates with the outlet line (16) to the lift rams thus informing the variable displacement pump regulator.

If the pressure in the rams is too high (shocks received by

the lifting arm), the valve (6) opens and the excess pressure is

directed to the return.

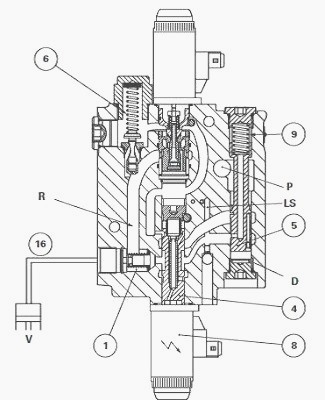

Down position

When the solenoid valve (7) is activated to lower the lifting arm, the

spool valve assembly (2) allows the oil coming from the rams to flow

into the return.

The LS pressure information is transmitted to the side of the flow rate regulating spool (5) (spring (9) side) and to the variable displacement pump.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader