________________________________________________________________________________

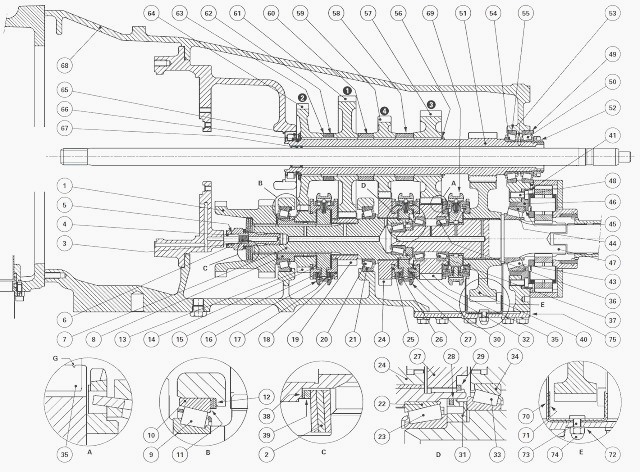

Massey Ferguson 8140, 8160 heavy gearbox 32 speeds

Massey Ferguson 8140, 8160 tractor heavy gearbox comprises 32 forward speeds and 32 reverse.

The transfer shafts and output shafts are supported by tapered roller bearings and are drilled as necessary to pressure-lubricate the bearings, the idler gears and the Hare or Tortoise synchronization system.

The lay shaft is supported at the front by a cylindrical roller bearing and at the rear, by two tapered roller bearings. The main gearbox comprises four synchronized gears.

An idler gear on the output shaft positively connected via a double cone synchromesh doubles the four synchronized gears, to give the eight basic speeds.

All pinions are helically cut and in constant engagement. The drive

shaft of the direct-drive clutch traverses the layshaft. The input unit

assembly located at the front provides four input ratios into the main

box.

MF 8140, 8160 heavy gearbox 32+32 Components

(1) Input gear (2) Belleville washers (3) Special screw (4) Lube tube

(5) Snap ring (6) Spring (7) Transfer shaft (8) Bush (9) Bearing cone

(10) Bearing cup (11) Shim(s) (12) Thick shim (13) Driving pinion (2nd)

(14) Synchromesh cone (2nd) (15) Synchro ring (2nd) (16) Synchro (1st -

2nd) (17) Synchro ring (1st) (18) Synchromesh cone (1st ) (19) Driving

pinion (1st ) (20) Bearing cone (21) Bearing cup (22) Bearing cup (23)

Bearing cone (24) Driving pinion (4th) (25) Synchromesh cone (4th) (26)

Synchromesh ring (4th) (27) Synchro (3rd - 4th) (28) Seal ring (29) Snap

ring (30) Synchromesh ring (3rd) (31) Special washer (32) Synchromesh

cone (3rd) (33) Bearing cone (34) Bearing cup (35) Driving pinion (3rd)

(Hare) (36) Bearing cup (37) Bearing cone (38) Shim(s) (39) Thick shim

(40) Tortoise gear (41) Centering pin (43) Bearing cone (44) Bearing cup

(45) Shim(s) (46) Rear bearing (47) Output shaft (48) Screw (49) Bearing

cup (50) Bearing cone (51) Layshaft (52) Nut (53) Shim (54) Bearing cone

(55) Bearing cup (56) Circlip (57) Driven pinion (3rd) (58) Spacer (59)

Driven pinion (4th) (60) Spacer (61) Driven pinion (1st) (62) Spacer

(63) Shim(s) (64) Driven pinion (2nd) (65) Washer (66) Snap ring (67)

Needle roller bearings (68) Gearbox housing (69) H/T synchromesh (double

cone)

The Massey Ferguson 8160, 8140 gearbox drive is provided by input gear

(1) integral with transfer shaft (7). The two hubs of synchromesh gears

(16) and (27), as well as gear (1) are hard-mounted to transfer shaft

(7) by splines.

First gear (19) and fourth gear (24) are idler gears on shaft (7). Second gear (13) is an idler gear on bush (8), which is hard-mounted to shaft (7) by splines.

Third gear 3rd (35) is installed on tapered roller bearings. All the

pinions on layshaft (51) are splined to and rotate with the latter. The

gear teeth on shaft (51) mesh with tortoise gear (40) which idles on the

output shaft.

Low range (Tortoise)

A synchronized gear is engaged by moving of one of the slides of

synchromesh gears (16) or (27) for engage transfer shaft (7) in one of

the four idling pinions.

Irrespective of the speed selected, the movement is transmitted to layshaft (51).

Output shaft (47) is driven by the gear teeth machined on

the layshaft intermeshing

with tortoise gear (40), engaged to output shaft (47), by moving the

slide of synchromesh gear (69) rearwards.

High range (Hare)

This range is selected by forward movement of the slide of synchromesh

gear (69), which establishes a direct drive between third gear (35) and

output shaft (47).

Consequently in 3rd gear, layshaft (51) is passive.

The other gears are

obtained by moving the slides of synchros (16) or (27) as for the Low

range.

Lubrication

The lube oil is supplied from tube (4) connected to the input unit. It

circulates in a series of axial channels, one of which crosses the

transfer shaft while the other is

blind, machined in the output shaft.

Radial channels feed the various pinions, the bearings and the Hare or Tortoise synchromesh. Needle roller bearings (67) are lubricated by an oil film circulating between the direct-drive shaft and the layshaft.

The shaft-end bearings

on shaft (51) are lubricated

by an additional oil flow from the drive bearing of the hydraulic pumps

located on the rear-axle intermediate housing, via radial ports drilled

respectively in shim (53)

and the shaft.

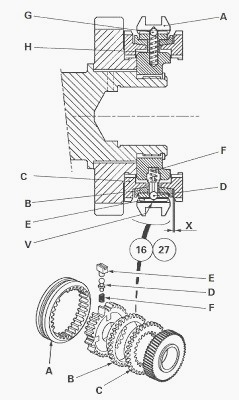

Synchromesh gears single cone

MF 8160, 8140 gearbox synchromesh gears single cone

Locking position

Axial displacement of slide A presses synchronization brake B against

friction cone C through the action of balls D and pressure system E.

The

speed difference

existing between the parts being coupled causes a radial rotation

limited by pressure system E resulting in turn in a pressure causing the

chamfered teeth of

synchronization brake B to move against slide A, opposing all relative

movement of the latter.

The pressure exerted by slide A and the angular difference of

synchronization brake B create an axial pressure between the friction

cones of synchronization brake

B, and cone C, due to the chamfers of the gear teeth; this axial

pressure establishes synchronism by progressive reduction of the speed

difference of the parts to

connect.

Once synchronism is established, the persistent pressure exerted by

slide A against synchronization brake B returns the latter backwards

until the teeth of slide A

are opposite the recess in synchronization brake B.

At this moment, the

resistance applied till this point preventing movement of slide A during

gear changing is

overcome and slide A can thus mesh without noise in the gear teeth of

cone C on the gear to be brought into drive.

The rigid connection between the shaft and the gear is now established,

and the gears change. If during gear-changing both gears end up

tooth-on-tooth, the

chamfers machined on the tooth flanks displace the arriving gear until

each tooth is opposite a recess.

Neutral position

Slide A is in the central position. The balls are pushed back into the

groove at V on slide A by pressure springs F.

The pinions are free to

turn on the shaft. In this

neutral position, slide A is locked by three balls G maintained by

springs H.

Overhaul

In the event of removal of the synchromesh gears, check the wear of

synchronization brakes B.

Place Cone C on a flat surface and position brake B in abutment by rotating it a few turns under finger pressure.

Measure dimension X at several points using a set of feeler gauges: if a value of less than

0.8 mm is found, check the cone and install a new brake B.

Value of dimension X with brake and new synchromesh cone

- synchro (1st - 2nd) (16): 0.9 to 1.5 mm

- synchro (3rd - 4th) (27): 0.9 to 1.5 mm

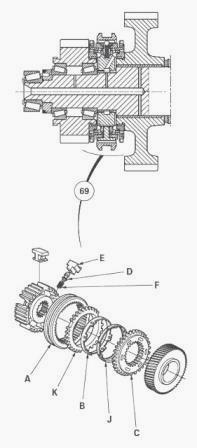

Synchromesh gears double cone

MF 8140, 8160 gerbox synchromesh gears double cone

Locking position

Axial displacement of slide A provides a thrust against ring K, which in

turn bears on synchronization brake B, pushing it towards Cone J through

the action of balls

D, spring F and pressure system E.

When the corresponding pinions are at the required speed, the slide

meshes with the coupling flange C of the candidate gear.

Locking of the synchromesh in position (and the neutral position) employ

the same principle as for single cone synchromesh gears.

Advantages of the double cone synchromesh

- better reliability

- increased stress strength

Overhaul (double cone)

- If needing to disassemble synchromesh (69), check the wear on

synchronization brakes B.

- Proceed by stacking coupling flange C, cone J, synchronization brake B

and ring K.

- Position brake B correctly by alternately rotating it through a few

turns and applying finger pressure.

- Using a set of feeler gauges, measure dimension at three equidistant

points. Take the average of\ the three readings.

Value of dimension

- on a new synchromesh gear, dimension must be 1.6 mm minimum;

- after operation, if this dimension is less than or equal to 0.60 -

0.80 mm, replace the synchronization brake B.

- Repeat the measurement of using the same process.

- If dimension remains incorrect, also replace ring K and cone J or the

complete synchromesh if required.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader