________________________________________________________________________________

Massey Ferguson 8260, 8270 heavy duty gearbox - Creeper unit

Massey Ferguson 8260, 8270 tractor fitted with heavy duty gearbox may also be fitted, depending on the options, with a creeper gear reducer unit.

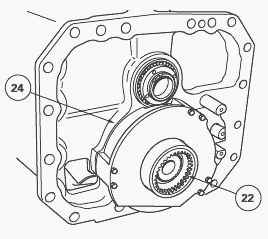

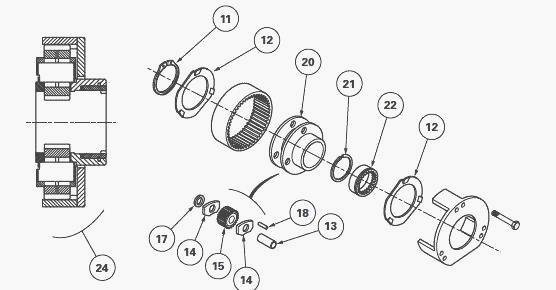

This reducer unit (24) consists of a simple epicyclical gear train comprising a planetary carrier and a crown and placed at the rear of the heavy duty gearbox.

The link fitted to the front right-hand side of the intermediate housing

operates the control fork of the reducer via a cable linked to a lever

located in the tractor cab.

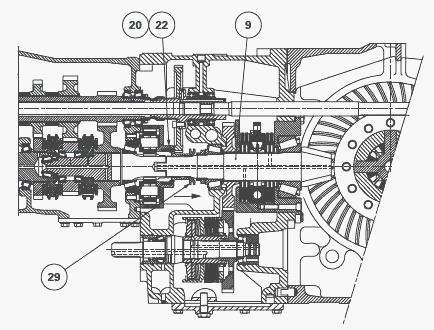

The coupler can only be activated when the MF 8260, 8270 tractor is

halted pinion (9). Moving the control lever towards the "Snail" position

moves the coupler to the rear and connects it to the planetary carrier

(20) via the intermediary of the coupler ring (22).

The rotational speed of the drive pinion is one quarter of that of the

output shaft of the gearbox. In normal gears, when the coupler is moved

forward the output shaft of the gearbox is linked to the drive pinion,

thus ensuring direct transmission.

Lubrication - The lubricating of the epicyclical reducer is carried out

by splashing caused by its moving components.

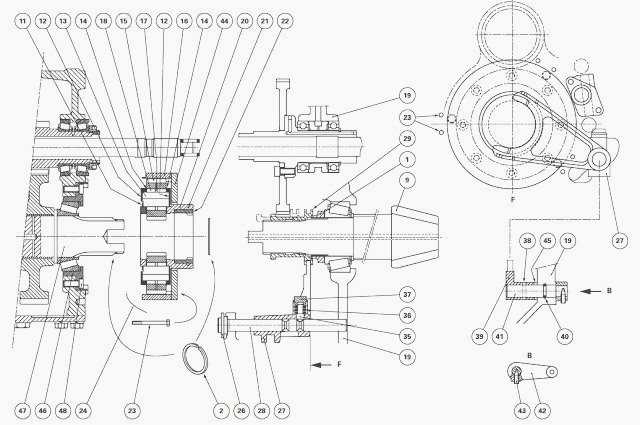

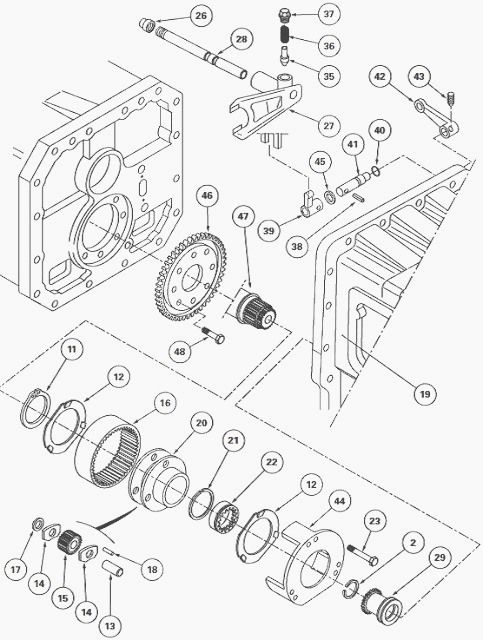

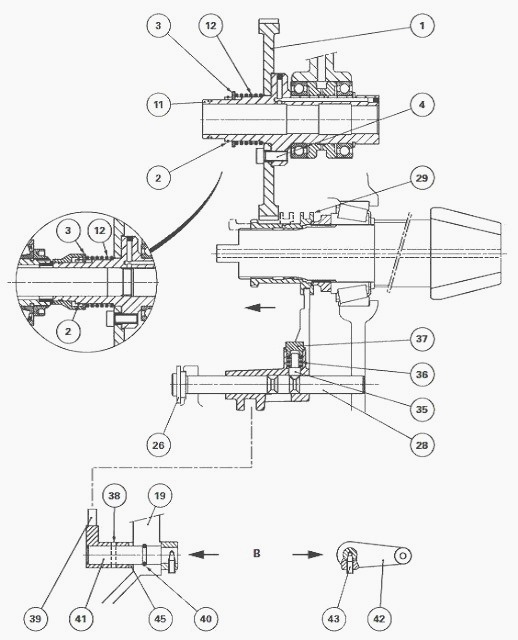

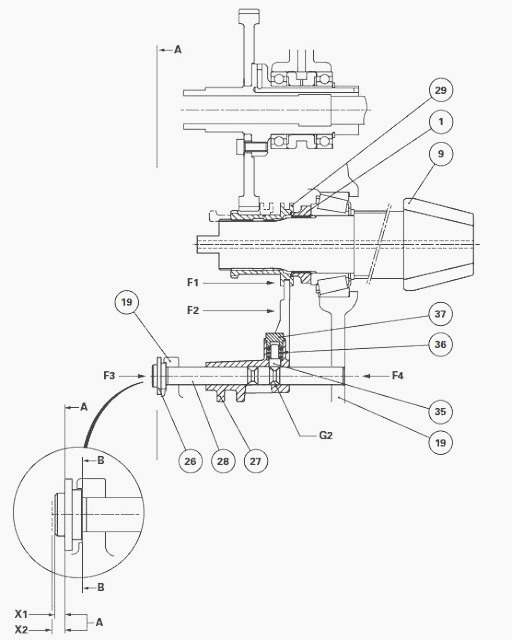

(1) Nut (2) Ring (9) Drive pinion (11) Snap ring (12) Friction washers

(13) Pins (14) Friction plates (15) Planetary gears (16) Crown ring (17)

Spacers (18) Needle bearings (19) Intermediate housing (20) Planetary

carrier (21) Snap ring (22) Coupler ring (23) Bolt (24) Planetary

carrier assembly (reducer) (26) Nut (27) Fork (28) Selector rail (29)

Link (35) Locking stud (36) Spring (37) Plug (38) Pin (39) Index (40)

O’ring (41) pin (42) Link (43) Bolt (44) Housing (45) Shim(s) (46)

Splined bearing (47) Output shaft (48) Bolt

Removing and remounting the Unit

Uncouple the Massey Ferguson 8270, 8260 tractor between the gearbox and

the intermediate housing.

Removing the unit

Take off ring (2) and bolt (23) fitted respectively to the output shaft

(47) and the housing (44).

Remove the components making up the reducer assembly (24) on the

gearbox.

On heavy duty gearboxes fitted with a creeper gearbox, bearing (46) is

different from that fitted to the standard version.

Machined splines on its edge connect it to the crown ring (16).

Refitting

Carry out a visual inspection of all components.

Lightly smear the faces of the reducer with miscible grease and fit the

friction washers (12) with their tabs located in the appropriate

grooves.

Replace the reducer assembly on the output shaft

- a machined area on the external diameter of the crown ring ensures

that the rear cup of the layshaft of the gearbox stands clear.

- the cutaway part of the housing (44) faces downwards.

Check the correct positioning of the components and tighten bolts (23)

smeared with Loctite 241 to a torque of 10 - 14 Nm. Manually check for

the rotation of the

gearbox output shaft.

Couple the MF 8270, 8260 tractor between the gearbox and the

intermediate housing.

Disassembling, reassembling and adjusting the selector

Uncouple the MF 8260, 8270 tractor between the gearbox and the

intermediate housing.

Disconnect the control cable fitted to the link (42).

Disassembly

To take off the coupler (29), it is necessary to remove drive pinion (1)

from the hydraulic pumps. Remove plug (37), recover spring (36) and

locking pin (35).

Remove the selector rail assembly (28) and nut (26). If necessary, break

the seal, unscrew and take off nut (26). Remove rear ring (2), take off

the lug washer (3)

and spring (12). Immobilize the pinion and remove bolts (4).

Extract pinion (1) from bearing (11) and simultaneously take out the

assembly (pinion, fork and coupler) through the front of the housing.

Remove the control link (42) located on the right hand side of the

intermediate housing. Drive out pin (38) and remove index (39). Recover

the shim(s) (45) and

remove pin (41) complete with o’ring (40).

Refitting

Lubricate a new o’ring (40) and place it on pin (41).

Place the pin in the chamfered port located on the exterior of the

intermediate housing (19).

To limit the axial clearance, it is recommended to shim to a tolerance

of 0.1 to 0.6 mm.

Shimming

On the axle, place the approximate thickness of shims (45). Fit index

(39) and partially place the pin (38). Refit the link (42) and bolt

(43).

Manually evaluate the clearance.

The adjustment principle consists of obtaining the minimum clearance

between the various components.

Action

If the clearance is outside the maximum allowed tolerance, determine a

new thickness of shims required. After shimming, check for correct

orientation of the index

and the link.

Definitively insert pin (38), fit and tighten Allen screw (43). Rearrange the assembly (pinion, coupler, and fork) in the intermediate housing. Immobilize the pinion again.

Fit and tighten the bolts (4) lightly smeared with Loctite 241 to a torque of 72 - 96 Nm. On bearing (11), replace in their correct positions the spring, lug washer and ring. Refit the selector rail and nut assembly.

Adjust the fork.

Couple the tractor between the gearbox and the intermediate housing.

Reconnect the control cable and where necessary carry out its

adjustment.

Adjustment

- Fit locking stud (35), spring (36) and plug (37). Partially tighten

the plug.

- Place coupler (29) in the F1 “creeper gear” position, the rear face

thrusting against the M60 nut (1).

- In F2, maintain the fork thrust against the coupler.

- In F3, turn the selector rail (28) in nut (26) so as to place in

contact the oblique side of groove G2 with locking pin (35) while

simultaneously holding nut (26) against

spotface B of the intermediate housing (19).

- Using a depth gauge, measure distance X1 between the front face of the

selector rail and face A of the housing.

- In F2, maintain the fork thrust against the coupler.

- In F4, turn the selector rail in the nut so as to place the other

oblique face of groove G2 in contact with the locking stud while

maintaining nut (26) as previously.

- Measure distance X2 in the same way as X1.

- Determine the X adjustment position using the following formula: X =

(X1 + X2) 2

- Provisionally position the selector rail (28) at dimension X.

- Place the coupler (29) in the "direct drive" position; manually check

the locking of the control and the clearance between the fork and the

coupler. Take care also

that the coupler is not in contact with the hydraulic pumps drive

pinion.

- If this check is satisfactory, take out plug (37), the spring and the

locking pin.

- Degrease the threads of the selector rail and those in nut (26).

- Lightly smear the nut threads with Loctite, tighten the nut and

definitively position the selector rail, in accordance with the

previously calculated dimension X.

- Lock the nut by bending its collar into the machined slot on the

selector rail.

- Replace the locking assembly. Tighten plug (37) to 50 - 70 Nm.

Disassembling and reassembling the epicyclical reducer

Disassembly

Remove the unit. Take off the circlip (11). Remove the friction washers

(12).

Drive out the pins (13) Remove the planetary gears (15) from the

planetary carrier (20) taking care not to lose the needles (18), the

spacers (17) and friction plates

(14).

The coupler ring (22) is inserted into the planetary carrier using a

press. The snap ring (21) ensures additional locking of the various

components.

Reassembly

Inspect and clean all components. Replace any defective parts.

Fit each planetary gear with two rows of needles smeared with miscible

grease and separated by a spacer.

Replace the planetary gears and position the friction plates (14). Refit pins (13), correctly orienting them to correspond with snap ring (11).

Place the snap ring. Manually check the axial clearance and rotation of each planetary gear.

Lightly smear the faces of the reducer with miscible

grease and fit the friction washers (12), with their lugs lodged in the

appropriate grooves. Refit

the unit.

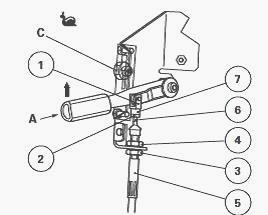

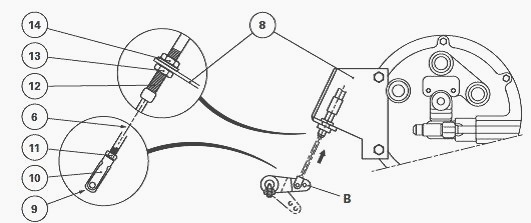

Control adjustment

On lever "A"

Place control lever “A” in the “Snail” position. Screw clevis (1) flush

with the threaded part of the cable (6). Mount clevis (1) on lever "A"

with clip (7). Tighten nut (2).

Tighten nut (3) on the knurled sheath end (5). Fit the knurled sheath

end and Grower washer onto the support piece. Tighten nut (4) while

checking that the cable is

not pinched.

On link "B"

Place link "B" in the "creeper gearbox" position (coupler (29) engaging

the splines of the planetary gear carrier (20) (Fig. 2) and with the

fork locked).

Screw clevis (9) flush with the threaded adjuster of the cable (6). Fit the clevis (9) on to link "B" using clip (10). Tighten nut (11).

Adjust the stop (12) using nut (13) on support (8) while checking that link "B" is still correctly locked.

Tighten nut (14) and check that the cable is not pinched. Check the operation and locking of the control in the "direct drive" position.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader