________________________________________________________________________________

Massey Ferguson 8240, 8260 gearbox dynashift with power shuttle - Removing and install

Uncouple the Massey Ferguson 8240, 8260 tractor between the engine and the gearbox.

Drain the gearbox. Remove the selector cover. Remove the clutch cover plate, hydraulic control unit and front clutch from the power. Remove the input unit.

Place the housing in vertical position and split the power shuttle rear

clutch from the input unit.

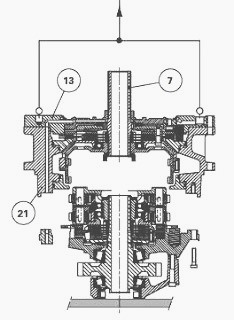

Removing and disassembling the cover, front

clutch casing and brake

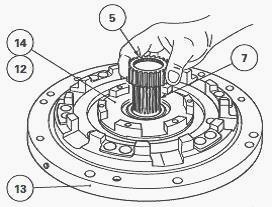

Using two locally made lugs or rings, remove the shaft (7), cover (13)

and casing (21) assembly.

recover both the stop (70) and the locating pin.

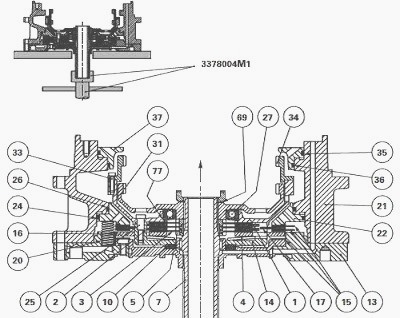

Remove the piston (37) from the casing (21). Scrap the O’rings (35)

(36).

Place the cover and casing assembly vertically on a workbench in which a

hole (O approximately 65 mm) has been drilled in order to accommodate

the

transmission shaft.

Immobilize the MF 8240, 8260 transmission shaft (7) and a locally made

spindle. Remove the screws (33) and split the secondary ring gear (34)

from the

secondary ring gear carrier (1).

Remove the circlip (69), pressing on the center of the primary ring gear

(31) in order to compress the spring washer (77). Remove the primary

ring gear (31) and

ball bearing (27). Recover the spring washer.

Hold the transmission shaft (7) and remove the screws (25). Take out the

secondary ring gear carrier (1).

Remove the casing (21) along with the piston (22). Remove the piston and

scrap the O’rings (24)(26).

Remove the discs (3) (15), intermediate plates (2), clutch plate (17),

hub (5), springs (20) and the thrust plate (16).

Extract the Belleville washer (4), clutch housing (14) and transmission

shaft (7) taking care to draw them towards the inside face of the cover

(13) and recover the

friction washer (10).

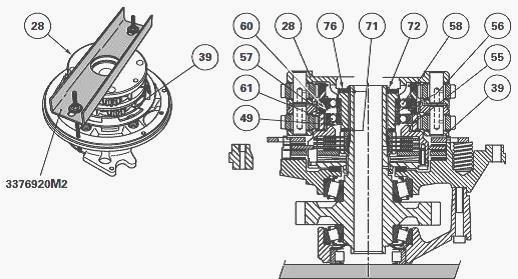

Removing and splitting the planet carrier unit

Removal

Compress the planet carrier assembly.

Remove the retaining ring (72). Remove the stud washer (76), planet

carrier assembly and the shims

(71) mounted along the mating faces of the primary planet carrier (28).

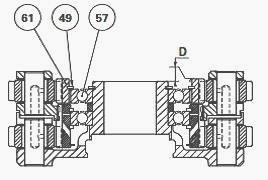

Remove the secondary sun gear (61) and the retaining ring (49) (if

necessary).

Remove the circlip (55). Remove the bearing (57) and the spacer (56).

Split the secondary planet carrier (39) from the primary planet carrier

(28).

Remove the retaining ring (60) and bearing (58).

Place the secondary planet carrier in vertical position.

Remove the

needles (63) by hitting the planet carrier gently against a wooden shim.

Split the planet carrier

from the primary sun gear (64) along with the retaining ring (62) and

oil splasher (75).

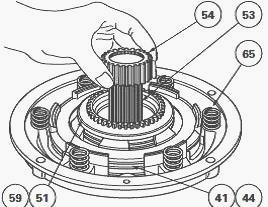

Remove the MF 8260, 8240 clutch plate (38), springs (65) and discs (41) (the latter should be separated from the clutch plate (44)). Remove the rear clutch housing assembly (59), thrust plate (45) and the last disc (41).

Remove the friction washer (51).

Remove the screws (46). Remove the cover (47) and the Belleville washers

(52). Separate the thrust plate (45), discs (50) and intermediate plates

(48).

Remove the hub (54).

Assembling the planet carriers

Clean and check parts, replace any defective ones.

Make sure the lubrication holes on the planet carrier axes are not

obstructed.

Check the axial clearance and rotation of each pinion gear by hand.

Assemble the primary sun gear (64), complete with retaining ring (62)

and oil splasher (75), on the secondary planet carrier (39).

Into each hole of the primary sun gear, slide a needle (63) home in the

groove of the secondary planet carrier.

Install the bearing (58), mount the retaining ring (60).

Assemble the secondary planet carrier on the primary planet carrier

(28). Turn the pinion gears to ensure they mesh correctly.

Position the spacer (56), bearing (57) and fit the circlip (55).

Check the primary pinion gears backlash by hand.

Assemble the retaining ring (49) (if it was removed) on the secondary

sun gear (61).

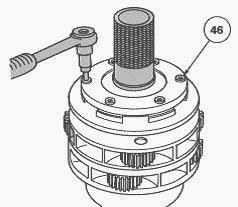

Installing the Massey Ferguson 8260, 8240 rear clutch and brake

Clean and check parts, replace any defective ones.Turn the planet carriers over in order to access the screws (46).

Install the secondary sun gear (61), the housing (59) and the hub (54),

with its internal grooves pointing downwards.

Assemble: discs (50), intermediate plates (48), the thrust plate (45),

the Belleville washers (52) as indicated in Fig. and refit the cover

(47). Center the housing

assembly (59) using tool.

Smear the screws (46) with Loctite 242 and torque them to 12 - 16 Nm.

Remove the tool.

Separate the housing unit from the planet carriers.

Coat the washer (51) with miscible grease and fit it on cover (47).

Type 648 Loctite or equivalent should be used to make the washer (78) glue to the cover (40). Install a disc (41). Install the housing assembly (59) and the washer (51) on the transmission shaft (53).

Assemble the hub (54), making sure its internal

grooves face upwards.

Install the two other discs (41) separated by the thrust plate (44).

Refit the springs (65).

Installing the cover, front clutch, brake and casing.

Check presence of rivets (23) on the cover (13).

If it proves necessary to replace the bearing (11), force fit a new

bearing (6) with its face flush with

the back end of the bearing.

Degrease the mating faces of the bearing and of the washer (12).

Apply a light coating of Loctite 648 or equivalent to one of the washer faces. Make the washer adhere to the bearing and leave to dry for a few minutes.

Place the bearing on the front cover (13) making sure to align the

lubricating channels. Lightly coat the screws with Loctite 242 and

torque them as follows:

M8 (42) : 20 - 28 Nm - M6 screw (9) : 12 - 16 Nm. Assemble the MF 8240,

8260 transmission shaft (7) via the inside surface of the cover and

the housing (14)

together with the washer (12).

Place the cover on a suitable fixture. Install the Belleville washer (4), a disc (15) and the thrust plate (16). Place the hub (5) on the transmission shaft (7) with the internal grooves facing upwards.

Assemble the discs (3) and the intermediate plates (2). Install the two remaining discs (15) one on each side of the clutch plate (17). Install the springs (20). Check presence of the rivets (74) on the spacer casing (21).

Make sure

the channels in the pistons (22) (37) within the casing (21) are not

blocked.

Lubricate the O’rings (24) (26) and assemble them on the piston (22) and

in the casing (21) respectively.

Position the piston in the casing and fit it using a small plastic

mallet to hit progressively round the edge.

Install the casing (21) on the cover (13). Check that the casing

lubricating channel aligns with that of the cover.

If either the cover (13) or the casing (21) is replaced it is necessary

to check and possibly renew the shimming of the power shuttle front

clutch.

Install the screws (18) and torque to 29 - 37 Nm.

Piston (22) hydraulic test

Connect a pressure gauge fitted with a valve and suitable fixture to the

front piston port. Feed the circuit with compressed air at 0.3 bar.

Close the valve and check

that pressure does not drop over a period of approximately 60 seconds.

Install the bearing (27) on the primary ring gear (31).

Refit the ring gears (31) (34), secondary ring gear carrier (1), bearing

(27) and spring washer (77).

Carry out operations 8 to 11 in reverse order.

In order to avoid any difficulties during assembly, refit the primary

ring gear (31) before tightening the screws (25).

Torque as follows:

- screw (25) : 31 - 35 Nm, Loctite 242

- screw (33) : 13 - 15 Nm, Loctite 242

Lubricate and assemble new O’rings (35) (36). Place the piston (37) in

the casing (21) and force fit it using a small plastic mallet to hit

progressively round the edge.

Piston (37) hydraulic test

- Use a suitable fixture to hold the piston.

- Check seal tightness as for the front piston.

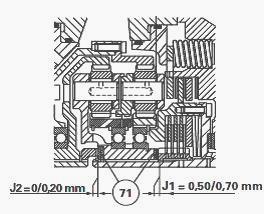

Shimming the planet carriers

For adjusting clearances J1 and J2, springs (65) and clutch plate (38)

must be removed.

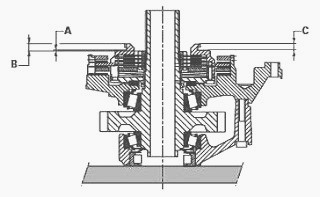

On rear clutch housing

Use a depth gauge to measure dimensions B and C at two opposing points.

Take the average of the two readings. Calculate dimension: A = B - C.

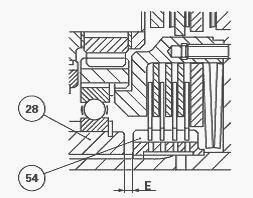

On the planet carrier assembly

Install secondary sun gear (61) complete with retaining ring (49) on

ball bearing (57).

Measure dimension D using a depth gauge.

Determine gap E between primary planet carrier (28) and hub (54)

according to the formula: E = A + D.

Fill space E with shims (71) having a value of E + 0.50 min. to + 0.70

max., to obtain a clearance of: J1 = E + 0.50 to 0.70 mm.

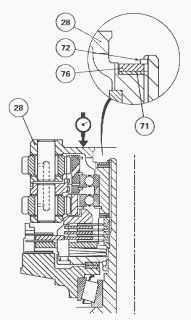

Adjusting J2 clearance

Place secondary sun gear (61) on housing (59) and the planet carrier

assembly on the shaft (53). Install washer (76) and ring (72).

Position the feeler of a dial gauge and check the clearance by moving

the planet carrier assembly vertically.

Depending on the measured clearance, select the thickness of shims (71)

to obtain J2 = 0 to 0.20 mm.

Remove the planet carrier assembly.

Install springs (65). Position clutch plate (38), ensuring that the

notches align with the tabs of the cover (40).

Ensure presence of shims (71) defined at operation.

Refit secondary sun gear (61) and planet carrier assembly and compress.

Set shims (71) selected at operation against the primary planet carrier

(28). Install washer (76) and ring (72).

Check the secondary sun gear backlash by hand.

Assembling the input unit

Screw two guide studs on the casing (21) (Optional). Check presence of

positioning pin and oil splasher on cover (40).

Use a sling to reinstall the transmission shaft assembly (7), cover (13)

and casing (21) aligning the positioning pin with its housing on the

cover (40).

Turn the shaft in order to engage the planet carriers in the ring gears.

Remove the guide studs (if used). Install the screws (30) and torque to

29 - 37 Nm, having lightly coated the threads with Loctite 242

beforehand.

Check shaft rotation

In case the cover (13) has been replaced, position the ring restrictor

(8) having first lightly coated it with Loctite 648. Check that the

product does not block the

lubricating ports.

Reinstall the power shuttle rear clutch.

Refit the input unit and the power shuttle hydraulic unit. Refit the

clutch cover.

Couple the tractor between the engine and the gearbox.

Top up housings with oil and check the level on the sight-glass on left at rear of central housing. Carry out a road test. Check the oil tightness of the hydraulic unions and of the selector cover mating face.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader