________________________________________________________________________________

Massey Ferguson 8260, 8270 Power Shuttle gearbox - Removing and install the front Clutch

Split the Massey Ferguson 8260, 8270 tractor between the engine and the

gearbox. Drain the gearbox and the centre housing. Remove the clutch

cover plate from the gearbox.

Remove the flange from each end of the pipe (78) and remove it.

Remove pipes (31) (74) (86) (87) and (94).

Remove the front clutch (2) and pull it from the housing using a locally

made tool.

Clean the parts. Replace any defective ones.

Check that PTO shaft (1) is installed.

Refit the clutch using the tool used for removal.

Replace the pipe seals (74) (94).

Install the pipes, carry out operation 5 in reverse order. Replace the

pipe seals (78) and refit them the pipe. Tighten the flange holding

screw at each end of the pipe to a torque of 25 Nm - 35 Nm.

Install the gearbox clutch cover plate. Top up the housing oil level and check it with the sight glass located at the rear left of the centre housing.

Couple the MF 8260, 8270 tractor between the engine and the gearbox.

Carry out a road test using the power shuttle and using ratios A, B, C

and D of the Dynashift. Check oil tightness of the mating faces and

hydraulic unions.

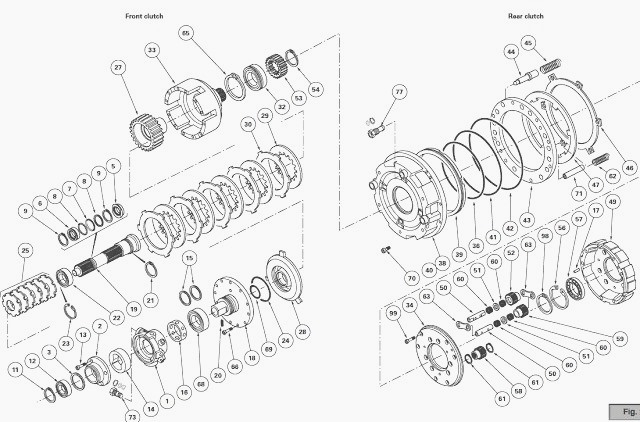

Disassembling and reassembling the MF 8270,

8260 front clutch

Separate cover (33) from unit (18). Remove the discs (29) and the

intermediate plates (30).

Remove the front snap ring (9). Remove the splined ring (6), the

anti-extrusion rings (8) and seal (7).

Remove circlip (11), take off cover (2) from the pump (14) complete with

bearing (12).

Pull the lubricating pump out of the pump unit (1) and take it apart

from the clutch housing (18).

Remove seal rings (15). If necessary, extract ring (16) and remove the

1.5 bar valve (73).

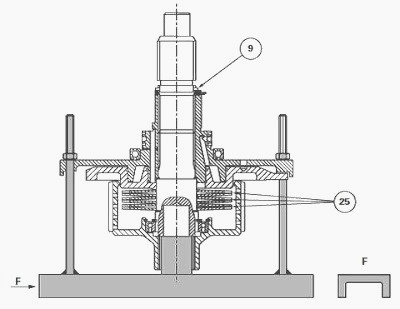

Place the partially disassembled clutch on a suitable locally made

fixture.

Compress the Belleville washers (25) and remove the rear snap ring (9).

Remove locking ring (5). Gradually release the Belleville washers.

Split unit (18) fitted with piston (28) from shaft (19).

Remove the Belleville washers.

Remove snap ring (23). Pull out the shaft (19) complete with bearing

(22) from hub (27).

Remove the circlip (21). Extract the bearing (22) from shaft (19).

Remove the piston. Remove seals (24) (69) and discard them. If

necessary, extract the bearing (68) from unit (18).

If necessary, remove snap ring (54) and remove the input sun gear (53).

Remove snap ring (65). Extract bearing (32).

Make sure that pin (20) is fitted.

If removed, fit the bearing (32) on cover (33), using a press and a

suitable tool. Install snap ring (65).

If disassembled, refit bearing (68).

Lubricate the new seals (24) (69) and fit them on the piston. Fitting piston (28). The angular position of the piston depends on the position of unit (18) lubricating ports. Align the indexing holes drilled in the unit and the piston. To align, use a pin of a suitable diameter.

Complete the installation of the piston by

gradually and alternately striking around its top rim with a plastic

mallet. Check that there are no fragments of the seal after assembly.

Using a suitable tool, force fit bearing (22) on shaft (19), the seal

side facing towards the rear clutch. Fit circlip (21).

Put the assembly (shaft, bearing, circlip) in the hub (27). Fit the snap

ring (23).

Install the Belleville washers.

Massey Ferguson 8270, 8260 Tractors can be fitted with six Belleville washers. Assemble unit (18) fitted with the piston (28) on shaft (19). Compress the Belleville washers using the tool.

Position ring (5),

aligning two of the flats with the flats on unit (18). Replace the rear

snap ring (9) and correctly

position it in the bottom of the groove.

Remove the fixture.

Check that the seal rings (15) turn freely in their grooves. Fit the

seal rings, lightly coated with miscible grease, making sure that they

do not protrude beyond the rim

of unit (18).

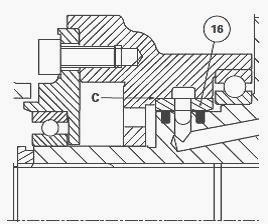

If necessary, fit the 1.5 bar valve (73) and tighten to a torque of 47 -

54 Nm. Insert ring (16) using a suitable fixture, with the chamfer “C”

in the direction.

Lubricate the bush. Assemble pump unit (1) on unit (18).

Lubricate pump (14) with transmission oil and position it aligning the

flats of the rotor with those on the unit (18).

Manually check the angular movement of the rotor on the flats of unit

(18).

Install bearing (12) on cover (2) of the pump. Install the cover.

Install circlip (11) and screws (13) and tighten to a torque of 36 - 46

Nm.

Lubricate and install a new assembly (O’ring (7) and anti-extrusion ring (8)). Slide on the splined bush (6). Install a new front snap ring (9). Soak the discs (29) in a transmission oil bath for approximately 1 hour.

Check that they are correctly saturated.

Position the intermediate plates (30), aligning the tabs and the discs

(29) on hub (27) according to the type of tractor.

Lightly smear the mating face of the clutch cover (33) on the unit (18) with Loctite 549 or its equivalent. Place the cover on the unit, the tabs of the intermediate plates lodged in the cut out notches on the clutch cover.

Fit and

tighten screws (66) to 25.5 - 34.5 Nm.

Manually check the rotation of the hub (27).

If necessary, refit the input sun gear (53) and fit snap ring (54).

Shimming the MF 8260, 8270 front clutch

This operation consists in obtaining an axial clearance of 0.60 to 0.80

mm between the pump cover (2) and clutch cover plate (4).

To carry out this operation, remove the PTO shaft so as to remove the

effect of the spring fitted at the rear end of the shaft to alow the

clutch assembly to move.

Install the clutch on cover (38) of the rear clutch.

Place a approx. thick 2 mm shim (3) on cover (2). Lubricate the lip of the cover plate seal . Protect the lip of the seal by fitting a protective material over the splines of the shaft (19).

Fit

two guide studs on opposite

sides of the gearbox housing and temporarily install the clutch cover

plate (4) without using Loctite. Gradually tighten several screws.

Place a dial gauge at the end of shaft (19) and check the clearance by

moving the shaft sideways.

Check that the snap ring (65) of bearing (32) is correctly in contact

with cover (38) by pushing the shaft (19) back as far as possible.

Remove clutch cover plate (4). Depending on the reading previously obtained with the dial gauge, define a new thickness for shim(s) (3) in order to obtain a clearance of between 0.60 mm and 0.80 mm.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader