________________________________________________________________________________

Massey Ferguson 8250, 8270 heavy gearbox - Selector rails

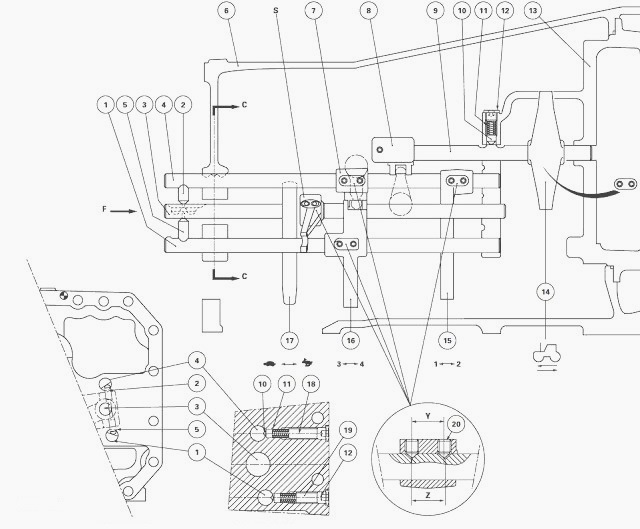

Massey Ferguson 8250, 8270 tractors fitted with a Heavy gearbox, the selector rails used for gear selection are located on the right-hand side of the gearbox behind the control cover.

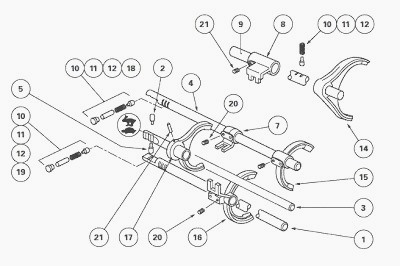

The gear selector comprises four selector rails of which three are for the gearbox and one for the input unit. Each selector rail supports its own fork and respective selector and moves longitudinally in end-bearings.

The forks are adjustable, thus ensuring a functional clearance between

the pads and the synchromesh sliding coupler.

Safety locking of the MF 8250, 8270 gearbox

selector

The system comprises two cylindrical locks of different lengths:

- short locking pin: selector rail 1st - 2nd

- long locking pin: selector rail 3rd - 4th

Their extremities are spherical and one of them has an extended lug.

Each selector rail is machined both to lodge and to allow movement of

the locks.

Operating principle

Example: Ratio 1 engaged - Hare range

When the selector rail is moved to select 1st gear, it forces its lock

to move out of its lodging place and to lock the range selector rail in

the "Hare" position.

At the

same time, this lock pushes another lock that in turn locks the 3rd -

4th selector rail, thus prohibiting any undue movement that might block

the gearbox. The same

reasoning applies to the Tortoise range and other gear ratios.

(1) Selector rail 3rd - 4th (2) Short locking pin 1st - 2nd (3) Hare /

Tortoise selector rail (4) Selector rail 1st - 2nd (5) Long locking pin

3rd - 4th (6) Gearbox housing

(7) Selector 1st - 2nd (8) Reverse shuttle selector (9) Reverse shuttle

selector rail (10) Locking pin (11) Spring (12) Plug

(13) Input unit housing (14) Reverse shuttle fork (15) Fork 1st - 2nd

(16) Fork 3rd - 4th (17) Hare / Tortoise fork (18) Long spacer (19)

Short spacer (20) Bolt (21) Pin

Disassembling and reassembling selector rails and adjusting forks and

gearbox selector

Uncouple the MF 8270, 8250 tractor between the gearbox and the

intermediate housing.

Remove the selector cover.

On tractors fitted with a creeper gearbox, the reducer unit located on

the rear face of the gearbox does not hinder disassembly or reassembly

of the selector.

Remove the bolts (20) from the selector (7) and forks (15) (16).

To carry out operations on the 1st - 2nd fork, use a short Allen key due

to the limited space between the fork and the housing.

Disassemble the index assemblies (10) (11) (12) (18).

Push selector rail (4) towards the front and remove lock (2). Proceed in

the same way for selector rail (1) and locking pin (5).

Take out selector rails (1) (4) through the rear of the gearbox.

Using a suitable pin punch, drive out pin (21) from the Hare / Tortoise

fork (17) (Fig. 88).

Take out selector rail (3) through the rear of the housing.

Remove the 3rd - 4th (16) and the Hare / Tortoise forks.

The 1st - 2nd fork (15) cannot be removed from the housing unless the

main shaft has previously been removed.

Clean and inspect the components. Replace any defective parts.

Install the selector rails, forks and selectors in the reverse order of

disassembly.

During refitting, pin (21) on the Hare / Tortoise fork must be replaced

- The short locking pin (2) locks selector rail 1st - 2nd.

- The long locking pin (5) locks selector rail 3rd - 4th.

- The index assembly (10) (11) (12) (18) places selector rail 1st -2nd.

- The index assembly (10) (11) (12) (19) places selector rail 3rd - 4th.

Adjust forks and selector (7)

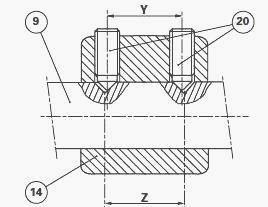

The positioning of forks (15) (16) and selector (7) is obtained via the

difference between the distance between the centre of threaded holes "Y"

and mark "Z" on the

selector rails (1) (4) (Fig. 87).

A different forward or rearward

movement of the forks is obtained by acting on bolt (20) as required.

The adjustment of forks is carried

out with the gear engaged.

Smear the plugs of the indexing assemblies (10) (11) (12) (18) with Loctite 542 or equivalent and tighten. Lock fork (15) in 1st. Maintain the synchromesh sliding coupler against the pinion.

Check that the rear pads are not in contact

with the synchromesh sliding coupler by slightly moving the selector

rail without moving the

sliding coupler itself.

Repeat the operation (fork locked in 2nd), checking that the rear pads are not in contact with the synchromesh sliding coupler, by using the same method as in operation.

Where necessary, adjust the fork using bolt (20)

previously smeared with Loctite 221 or equivalent.

Proceed in the same way to adjust fork (16).

Tightening torques

- Bolt (20): 35 Nm without modifying its adjustment, Loctite 221.

- Plug (12): 50 - 70 Nm, Loctite 542.

Next, adjust selector (7) in line with the selector incorporated in fork

(16).Adjust the "S" Hare / Tortoise selector.

Install the selector cover. With the gear lever in neutral, check that

locks (2) (5) are free in the rear bearing in the Hare / Tortoise range.

Couple the Massey Ferguson 8270, 8250 tractor between the gearbox and

the intermediate housing.

Road test. Check:

- gear changing

- correct operation of the Hare / Tortoise range.

Check oil tightness of the gearbox and intermediate housing mating

faces, selector cover and hydraulic unions.

Disassembling and reassembling selector rail and adjusting input unit

fork

Uncouple the MF 8250, 8270 tractor between the engine and the gearbox.

Remove the input unit.

Disassemble the indexing assembly (10) (11) (12).

Remove bolt (20) from the reverse shuttle fork (14).

Take out selector rail (9) and fork.

Clean and inspect the components. Replace any defective parts.

Install the fork and selector rail.

Carry out the adjustment of the fork.

Adjustment

The positioning of fork (14) is obtained by the difference between the

distance between "Y" and mark "Z" on the selector rails (9) (Fig. 89). A

different forward or

rearward movement of the forks is obtained by acting on the forward bolt

(20) or the rear bolt, as required.

Install the locking stud (10), spring (11) and plug (12) tightened to 50

- 70 Nm and previously smeared with Loctite 542 or equivalent. Fit bolt

(20) smeared with

Loctite 221 or equivalent.

Position the fork, locked at the front. Maintain the synchromesh sliding

coupler in thrust against the pinion. Pre-adjust the fork in accordance

with the above

principle.

Check that the front pads are not pinched against the synchromesh

sliding coupler.

Repeat the operation (fork locked at the rear). Check that the rear pads

are not pinched against the synchromesh sliding coupler.

The adjustment is correct when the space is identical between the pads

located on either side of the fork and the synchromesh sliding coupler,

when in the forward

and reverse positions.

Alternatively and progressively tighten bolt (20) to 35 Nm without

modifying its adjustment.

Install the input unit.

Couple the tractor between the engine and the gearbox.

Carry out a road test, checking for the correct operation of the mechanical reverse shuttle. Check for the oil tightness of the selector cover and hydraulic unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader