________________________________________________________________________________

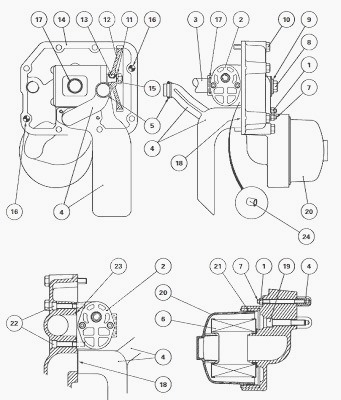

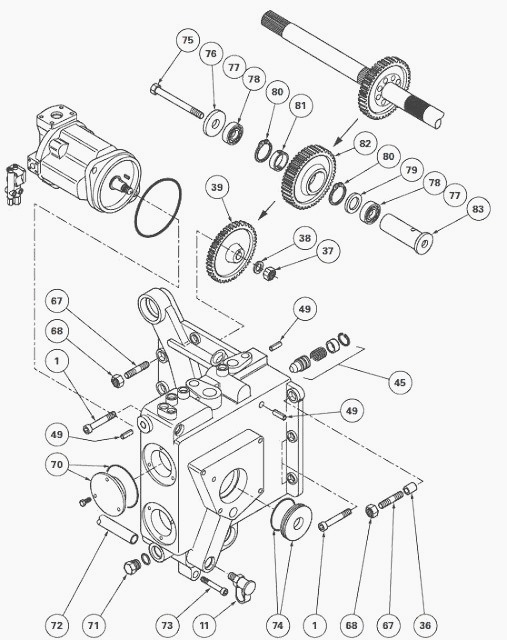

Massey Ferguson 8280, 8220 hydraulic system - Left-hand cover

The left-hand side cover (Load Sending

hydraulic system 150 l/min), fitted on the intermediate housing, forms

the support for the following components:

On its inside face

- the booster pump (2) the capacity of which differs depending on the

hydraulic characteristics as shown below.

- the suction manifold (4)

MF 8280, 8220 Load Sensing hydraulic circuit

Booster pump Variable - Displacement pump

60 cm3/rpm - 0-45 cm3/rpm

80 cm3/rpm - 0-60 cm3/rpm

On the outside face

- the 150 micron suction strainer (6) differs through the size of its

filtering surface and depends on the capacity of the variable

displacement pump (96 mm long with

the 60 cm3 pump and 139 mm long with the 80 cm3 version).

- The figures given in this section are for the 60 cm3 pump and its

surrounding elements. The construction of the 80 cm3 pump is identical

in principle to the former.

- It should be noted however, that the internal pinions as well as the

body of the pump have slightly different profiles.

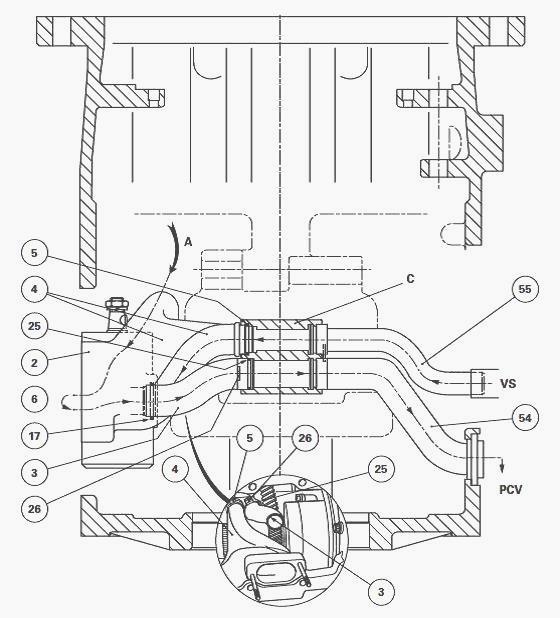

Pinion taking its rotation from shaft, drives pinion of the booster

pump. The oil is sucked into the intermediate housing via the manifold

(4). It is then directed towards

the strainer (6) and the booster pump through an internal channel in the

cover.

The oil is then discharged towards the Massey Ferguson 8280, 8220

variable displacement pump by the booster pipes (3) (54) held by

compartment ‘C’ of the

intermediate housing. The pipe (55) directs the oil coming from the 5

bar safety valve towards the suction manifold (4).

(25) O’ring (26) Mecanindus pin (54) Booster pipe (55) Safety-valve pipe

(depending on hydraulic characteristics), A - Suction, PCV - To the

variable displacement

pump (depending on hydraulic characteristics), VS - 5 bar safety-valve,

C - Compartment of the intermediate housing

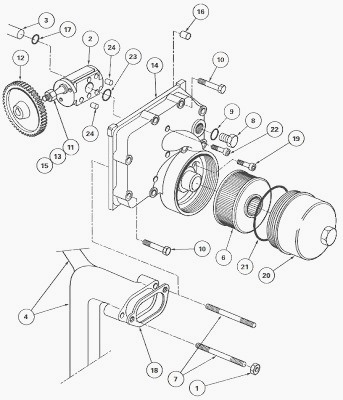

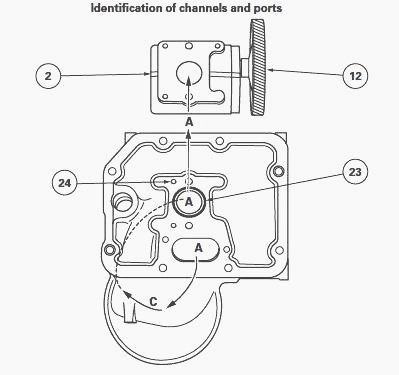

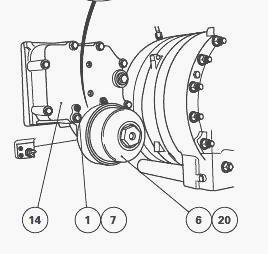

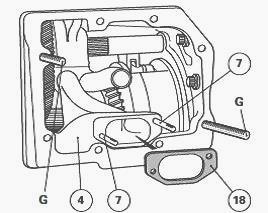

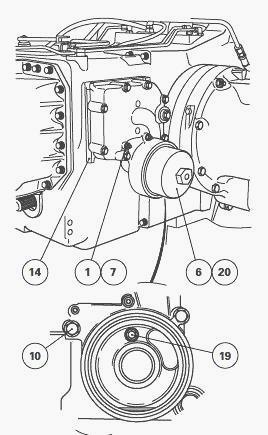

(1) Nut (2) Booster pump (3) Booster pipe (4) Suction manifold (5)

O’ring (6) Strainer (7) Studs (8) Plug (9) Seal (10) Bolt (11) Washer

(12) Pinion (13) Key (14)

Cover (15) Nut (16) Centring pins (17) O’ring (18) Gasket (19) Bolt (20)

Bowl (21) O’ring (22) Bolt (23) O’ring (24) Locating pins, A - Suction

from manifold (4), B -

Strainer (150 microns), G - Booster supply to the variable displacement

pump

Removing and refitting the MF 8220, 8280 hydraulic cover

Removal

Take off the wheel on the side concerned. Position an axle stand.

Partially drain the intermediate housing. Unscrew the bowl (20). Remove

the strainer (6).

Take off nuts (1) and bolts (10) (19). Remove the cover (14) and then

the suction manifold (4). If necessary, remove the studs (7).

Refitting

Clean the mating faces of the housing and the cover. Smear the mating

face of the housing with Loctite 510 or its equivalent.

Replace the O’ring (17) and position the seal (5) on the suction

manifold (4).

Refit manifold (4), the end fitted with seal (5) inserted into compartment ‘C’ of the intermediate housing. Lightly smear the face of the gasket (18) on the suction manifold (4) with Silicomet type silicone.

Spool the gasket over the

studs (7), the adhesive facing the cover. Screw two diametrically

opposed guide studs G on to

the intermediate housing.

Check for the presence of the two centring pins (16). Place a new O’ring

(25) on the booster pipe (3). Insert the pipe, its end positioned in the

Mecanindus pin (26).

Spool the cover on to the guide studs G and studs (7). Using a bronze hammer, tap the cover to engage the pins (16) in the housing. Take out the guide studs G.

Fit and alternately and uniformly tighten the bolts (10) (19) to a torque of 90 - 120 Nm. In case of any resistance felt while tightening, move the cover away from the housing and check the position of pipe (3) in the pump port.

Also turn pinion (12). Fit nuts (1) smeared with Loctite 241 and tighten to a torque of 15 - 20 Nm. If necessary, replace O’ring (21) on bowl (20).

Put the strainer (6) in

place and tighten the

bowl. Carry out operations in reverse order. Check the oil tightness of

the mating face of the cover as well as that of the bowl.

Tightening torques:

- Nuts (1): 15 - 20 Nm (Loctite 241)

- Bolts (10) (19): 90 - 120 Nm

- Wheel nuts or studs

- Bowl (20): moderate tightening.

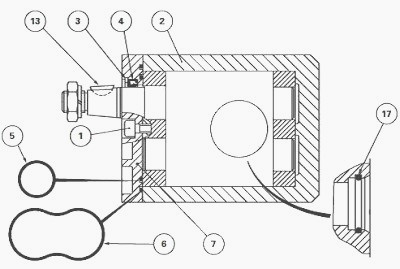

Removing and refitting the booster Pump

The removal and refitting procedures are the same for a 60 cm3 or 80 cm3

pump. Take off the Massey Ferguson 8220, 8280 hydraulic cover.

Remove bolts (22) and pump (2). If necessary, remove pinion (12) from

the pump. Recover key (13).

Clean the mating faces of the pump and cover.

Check for the presence of the locating pins (24).

Inside the cover, apply a bead ‘C’ of Loctite 574 or its equivalent

around the bolt holes. The diameter of the bead should be small in

section so as to not touch the

groove of seal (23). Fit a new seal.

If disassembled, replace key (23) and refit pinion (12). Tighten nut

(15) to the torque indicated below. Position the pump on the centring

pins.

Fit bolts (22) smeared with Loctite 241 or its equivalent and tighten to

a torque of 40 - 50 Nm. Manually check the rotation of the pump. Refit

the cover.

Tightening torques

- Nut (15): 50 - 60 Nm (Loctite 241)

- Bolt (22): 40 - 50 Nm (Loctite 241)

Replacing the booster pump seals

Whatever the hydraulic characteristics of the pump, the operational

procedure for the replacement of the seals remains identical. Remove the

left-hand side cover

and the booster pump.

Disassembly

Tighten the pump in a vice fitted with plastic jaw protectors. Remove

bolt and cover.

Take off circlip, seal and O’rings.

Refitting

Lubricate seal and insert it using an appropriate fixture. Place

circlip.

Lightly smear the O’rings with miscible grease and position them on the

cover.

Position the cover. Fit and tighten bolts to a torque of 30 - 40 Nm.

Manually check for the free rotation of the pump. Refit the booster pump

and the left-hand cover.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader