________________________________________________________________________________

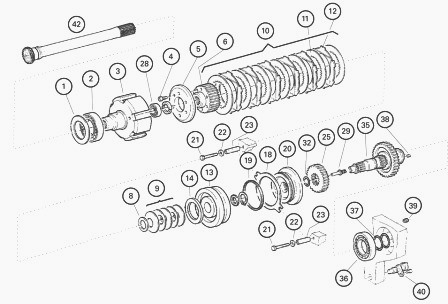

Massey Ferguson 8737, 8730 Dyna VT transmission PTO - Installing the set of discs on the disc carrier

MF 8737, 8730 PTO clutch

Massey Ferguson 8737, 8730 Rear PTO drive

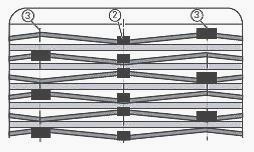

Start with an external blade. Next alternate with an internal blade

(11). Each internal blade (11) should be fitted in respect to the narrow

slot (pos. 2) while the wide slot (pos. 3) should be positioned either

side alternately.

Total number of discs: 7 external discs (12) and 6 internal discs (11).

Fit the disc carrier (6) together with the set of Belleville washers

(9). Fit the compression tool. Compress the MF 8737, 8730 clutch. Fit

the locking half-rings (30).

If the locking half-rings are chamfered on just one side, the chamfered side must face the disc carrier (6). If the disc carrier (6) does not fit into place, fit it without the set of discs (10) and mark the teeth.

Push the set of discs home, ensuring it is correctly centred. Measure the distance (uncoupling clearance) using laminated shims. Specified values: 1.75 to 3.50 mm.

If the minimum distance of 1.75 mm is not obtained, the discs are wrapped. Fit a new set of discs (10). Smear the thread of the nozzle (29) with plastic binder.

Tighten the nozzle (29) to a torque of:25 Nm. If necessary, fit the bearing (28) to its stop with its closed part facing upwards into the interior of the clutch cover (3). Fit the bearing (2) up against the clutch cover (3).

Adjust the position of the external discs (12) and fit the clutch cover (3) to its stop. Fit compensating shims (1) on the bearing (2). Measure and note the distance between the mating faces. For example: 178.6 mm.

The distance between the flange face and the mating face of the journal is written in white on the top part of the rear axle housing. Example: 178.71.

The distance between the journal of the bearing (2) and the flange face of the housing cover should be less than 0.1 to 0.2 mm, as the written value indicates. This means that the journal clearance must be 0.1 to 0.2 mm.

If not, correct it with compensating shims (1). The distance between the flange face and the mating face of the journal of the lower shaft is written in white on the lower part of the rear axle housing. Example: 148.75.

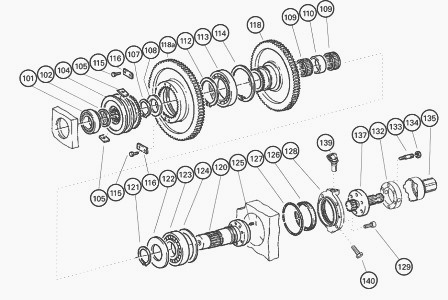

This value is not necessary in case of repair, because a dial gauge must be used to measure the bearing clearance. Check the bearing clearance of the lower shaft (120).

Fit the compensating shims (1) in the upper bore. Smear 4 new O’rings

with miscible grease and fit them at the position of the oil pressure

pipes.

Clean the housing mating face. Check the 2 locating pins are fitted

correctly. Smear the mating face with sealing product. Carefully raise

the housing cover and fit it on the rear axle housing. Tighten the M18

screws and nuts to a torque of: 400 Nm.

If necessary: Smear the outside of a new shaft sealing ring (126) with a

thin layer of sealing product (ref. X 903.051.711), and insert it until

it comes into light contact with the cover (128), the seal lips turned

towards the oil chamber. Depth approximately 5 mm. Fill the lip seals

2/3 full with miscible grease.

Fit the corresponding compensating shims (124). Smear new O’rings (127)

with miscible grease and fit them in the groove of the cover (128).

Smear the thread of the screws (129) with plastic binder (ref. X

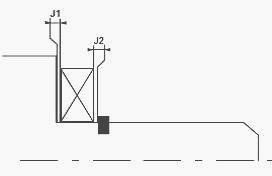

903.050.084) and tighten. Rotate the shaft (120) 10 times. Fit a dial

gauge. Push in the shaft (120) once and note the clearance value J2.

Rotate the shaft (120) 10 times. Fit a dial gauge. Pull once on the

shaft (120) and note the clearance value J1.

Total clearance J = J1+ J2. 0.02 mm < J < 0.07 mm. If not, correct it

with compensating shims (124). PTO end-fitting with 6 x 1’ 3/8" splines.

Also compatible:

PTO end-fitting with 21 x 1’ 3/8" splines

PTO end-fitting with 6 x 1’ 3/4" splines

PTO end-fitting with 20 x 1’ 3/4" splines

The PTO end-fitting has 4 drive holes for the PTO sensor. Fit the

end-fitting (137). Fit the spacer (132). Lock the end-fitting (137 with

a screw M16 (for easier assembly).

Tighten the nuts (134) (M0-10) to a torque of: 69 Nm. Top up the transmission oil level.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader