________________________________________________________________________________

Massey Ferguson 8730, 8737 hydraulic system - Disassembling and reassembling the pumps

The Massey Ferguson 8730, 8737 hydraulic steering pump is fitted at the end of the variable displacement pump. It is a 19cc fixed displacement pump, with a 120 bar maximum pressure and a gear ratio of 67/58.

It is fitted to the variable displacement pump by two CHC M8 screws. It

rotates around a coupling sleeve. The

variable displacement pump has maximum capacity of 60cc, and a 400 bar

maximum pressure.

The gear ratio is 67/58. Drive is transmitted directly to the gearbox by a gear train. The pump is fitted to the gearbox housing by two HM 12 screws.

The lubricating pump is a fixed displacement pump. It is a gear pump and

is fitted to the same drive pinion as the service pump. It’s capacity is

23.4cc.

Disassembling the steering pump and the

variable displacement pump

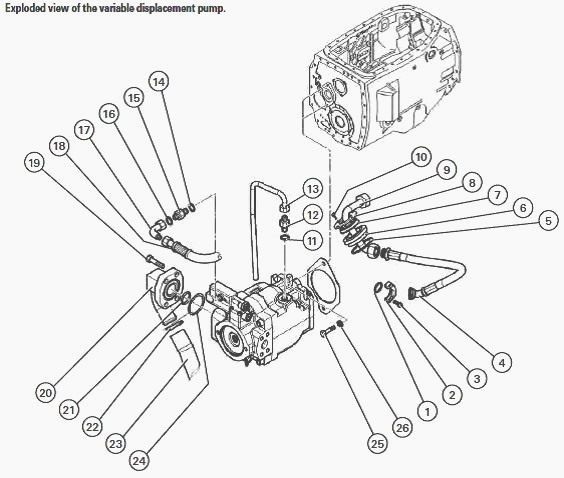

variable displacement pump

1 - O’ring, 2 – Flange, 3 – Screw, 4 – Hose, 5 – Gasket, 6 – Plug, 7 -

O’ring, 8 – Washer, 9 - Rigid pipe,10 – Screw, 11 - O’ring, 12 – Union,

13 - Rigid pipe, 14 -

O’ring,15 – Union,16 - O’ring,17 - Elbow union,

18 – Hose,19 – Screw, 20 – Flange, 21 - O’ring, 22 – Collar, 23 – Hose,

24 - O’ring, 25 – Screw, 26 - Washer

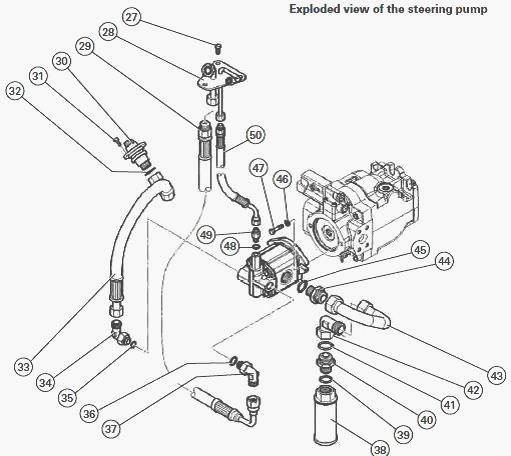

steering pump

27 – Screw, 28 - Union plate, 29 – Hose, 30 – Union, 31 – Screw, 32 -

O’ring, 33 – Hose, 34 – Union, 35 - O’ring, 36 - O’ring, 37 – Union, 38

– Strainer,39 – Seal,40

– Union,41 – Seal,42 – Union, 43 - Rigid pipe, 44 – Union, 45 - O’ring,

46 – Washer, 47 – Screw, 48 - O’ring, 49 – Union, 50 – Hose

Chock the MF 8730, 8737 tractor and take off the rear right-hand wheel.

Remove the exhaust system. Take off the right-hand protective guards.

Take off the

protective guard over the right-hand footstep. Remove the right-hand

footstep.

Drain and remove the fuel tank.

Drain the hydraulic oil. Remove the protective housings that might obstruct access. Disconnect the hydraulic pipes connected to the tank. Disconnect the hose (33) from the steering pump priority block. Take out the attachment screws (10) from the hydraulic pressure pipe of the variable displacement pump.

Take out the tank attachment screws.

Remove the oil tank. Take out the rigid pipe (9) through the port, then

disassemble it. Remove the hose (50) from the steering pump priority

block.

Take out the attachment screws (27) from the union plate (28).

Gently remove the plate from the spacer, and disassemble the hydraulic union from the priority block. Remove the “Load Sensing” control pipe from the variable displacement pump. Disconnect the hose (33) from the steering pump priority block. Loosen the collar (22), then disconnect the variable displacement pump suction hose (23).

Take off the rigid pipe (43) fitted with its strainer

(38). Access to the union is limited, so a 41 mm pipe wrench is

recommended. Remove the

union (44) from the pump. Take out the attachment screws (47) from the

steering pump. Remove the steering pump.

Discard the O’ring. Remove the coupling sleeve. Loosen and take out the

screws (3), then remove the pressure union of the variable displacement

pump. Access is limited, so a 10 mm multipurpose wrench is recommended.

Remove the return rigid pipe (13) to the variable displacement pump tank. Access is limited, so a 27 mm pipe wrench is recommended. Remove the screws (25) from the variable displacement pump flange. Access is limited, so an 18 mm offset pipe socket is recommended.

Support the variable displacement

pump across

the housing with a wooden shim, and pull the pump away of the gear

teeth. Take the pump out of the spacer;

Discard the paper gasket. It is recommended to turn the suction channel

of the pump upwards and to remove an attachment stud from the tank to

extract the pump

more easily.

Reassembling the steering pump and the variable displacement pump

Grease and fit new seals. Screw two M12 guide studs into M12 screw holes

to assist pump assembly. Insert the variable displacement pump into the

spacer and

slide it onto the studs. A wooden shim can be fitted to assist pump

positioning. Take out the guide studs and attach the pump using the two

M12 attachment screws

(25).

Tighten the M12 screws (25) to a torque of: 86Nm.

Fit the return rigid pipe (13) to the variable displacement pump tank.

Access is limited, so a 27 mm pipe wrench is recommended. Fit the

variable displacement

pump pressure hose (4). Tighten the screws (3) to a torque of: 50Nm. Fit

the coupling sleeve of the two pumps.

Fit a new O’ring on the steering pump centring diameter, and fit the steering pump in its housing. Fit and tighten the steering pump screws (47) to a torque of: 25Nm. Fit the steering pump union (44). Fit the steering pump rigid pipe (43) fitted with its strainer (38).

Connect the hose (23) on the variable

displacement pump suction

channel, and tighten the collar (22). Attach the hose (33) on the

steering pump priority block. Fit the elbow (17) on the variable

displacement pump. Fit the MF 8730,

8737 steering pump priority block hose (50) and tighten the three screws

(27) to a torque of: 10Nm.

Fit the hose (50) on the steering pump priority block. Take out the pressure hose (4) from the variable displacement pump through the spacer plug (6), and connect it to the rigid pipe (9) of the washer (8). Refit the stud if removed when extractng the pump. Clean the mating faces of the tank and spacer.

Smear one of the cleaned surfaces with sealing product. Fit the hydraulic tank. Fit and tighten the tank attachment screws. Tighten the screws (10) of the washer (8). Fit the hose to the union (30). Fit the tank hydraulic channels. Refit the protective housings that were removed. Refit the fuel tank. Refit the footstep.

Refit the

protective guard over the right-hand footstep. Refit the right-hand protective guards.

Refit the exhaust system. Top up the hydraulic oil (approximately 65L).

Check the operation and tightness of the hydraulic circuit. Repair any

defective elements or

seals. Refit the rear right-hand wheel.

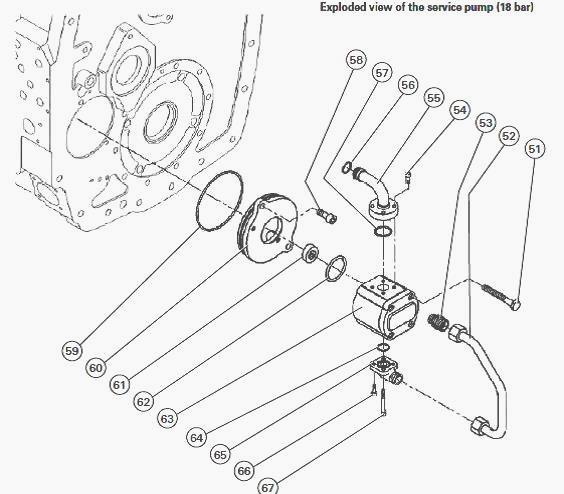

service pump (18 bar)

51 – Screw, 52 - Rigid pipe, 53 – Union, 54 – Screw, 55 – Union, 56 -

O’ring, 57 - O’ring, 58 – Screw, 59 - O’ring, 60 – Cover, 61 – Catchdog,

62 - O’ring, 63 -

Hydraulic pump, 64 - O’ring, 65 – Insert, 66 – Screw, 67 – Screw

Disassembling the lubricating pump

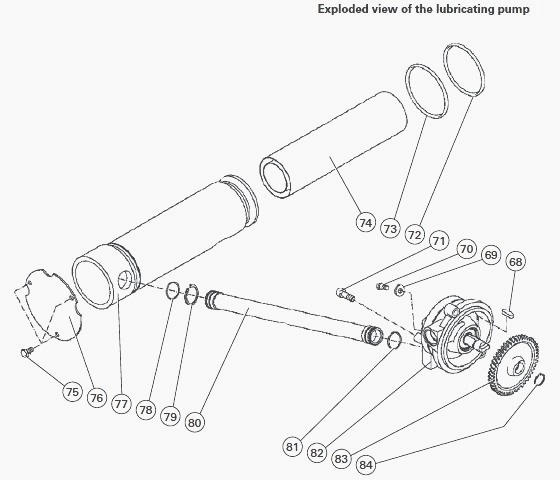

Lubricating pump

68 – Key, 69 – Washer, 70 – Screw, 71 – Screw, 72 - O’ring, 73 - O’ring,

74 – Filter, 75 – Screw, 76 – Cover, 77 - Suction filter, 78 - O’ring,

79 – Circlip, 80 – Pipe,

81 - O’ring, 82 – Pump, 83 - Drive pinion, 84 – Circlip

Remove the Massey Ferguson 8730, 8737 transmission unit. Take out the

screws (75), then remove the cover (76). Remove the filter (74). Loosen

the pipe on the

pressure filter side.

Loosen the pipe on the rear axle side. Remove the circlip (79) from the suction pipe. Fit home the suction pipe in the suction filter pipe to release it from the pump. Loosen and remove the 2 screws (71).

Remove the lubricating pump.

Remove the suction pipe. Discard the O’rings. Take off the pump pinion

circlip (84). Remove the pump pinion (83). Take off the key (68).

Check the pump condition, and replace it if required.

Reassembling the lubricating pump

Fit the key (68) in its housing. Fit the drive pinion (83). Fit the

shaft circlip (84). Fit the pump in its housing in the gearbox. Hold it

in position using 2 screws.

Refit the pipe on the pressure filter side and rear axle side. Prepare the suction pipe. Fit the 2 O’rings (81) and circlips (79).

Fit the side not fitted with the O’ring in the suction filter pipe (77). Smear the O'ring with miscible grease and fit home the pipe in the suction pump.

The circlip groove on

the suction filter pipe side must be cleared. Smear it with miscible

grease, then slide the

O’ring into its groove. Fit the circlip in its groove.

Fit the pipe into

the suction filter until it abuts against the circlip. Fit the circlip

on the pipe, on the pump side.

Definitively tighten the pump attachment screws to a torque of: 25 Nm.

Fit the suction filter (74). Fit the cover (76) using the 3 screws (75). Tighten the screws (75) to a torque of:25Nm. Refit the transmission unit.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader