________________________________________________________________________________

MTZ Belarus Tractor hydraulic power steering

Forward-Motion hydraulic power

steering

The hydraulic power steering is intended for controlling the turning of

the steerable wheels and reducing the force to be applied to the

steering wheel for turning the tractor.

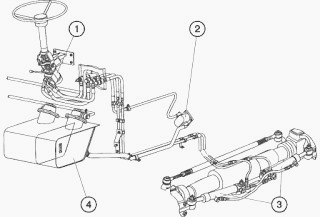

The hydraulic power steering consists of a metering pump (1), two

differential hydraulic cylinders (3) executing the turn, feeding pump

(2) driven from the engine and hydraulic fittings.

The hydraulic power steering oil tank is the right-hand section of the

oil tank (4) with the 25-micron filter of the working fluid.

Fig.1. MTZ Belarus Tractor steering

1 – metering pump; 2 – feeding pump; 3 – hydraulic cylinders; 4 – oil

tank.

Construction and Operation of the

hydraulic power steering

The direct-acting metering pump (1) is installed on the bracket of the

steering column; the turn hydraulic cylinder (3) – on the brackets

attached to the front axle and the feed pump (2) – on the engine.

The metering pump is connected to the chambers of the hydraulic cylinder

of turning, feed pump and oil tank via pipe-lines.

When in a straight-ahead motion, the cylinder chambers are closed by the

metering pump spool belts, and the oil fed from the feed pump and

brought to the metering pump returns to the oil tank.

When the steering wheel is turned, the metering spool-valve is displaced

providing in such a way for oil supply to the chambers of the hydraulic

cylinder of turning in the amount proportional to the angle of turn of

the steering wheel.

Recommendations for Operation of the

hydraulic power steering

When assembling the MTZ Belarus Tractor

hydraulic power steering:

- Install properly the oil pipelines and hoses in accordance with the

hydraulic diagram;

- Protect the connecting holes of the metering pumps, hydraulic

cylinders, poi pipelines and high-pressure hoses against penetration of

dirt;

- Prior to starting the engine, check the tightening of all the

connections of the hydraulic power steering hydraulic system;

- When tightening the fasteners, apply the required torque;

- Fill the oil tank to the upper limit as seen on the level indicator;

Bleed air from the MTZ Belarus Tractor hydraulic system.

To do this, proceed as follows:

- Start the engine. Turn the steering wheel in both directions 3-4 times

at the idling rotational speed of the engine without reaching the

extreme positions of turning of the steerable wheels.

- Add oil to the tank to the required level.

- Turn the wheels from one stop to an-other 2-3 times. Hold the steering

wheel at the extreme positions for 4...5 seconds.

- If necessary, eliminate the oil leaks and add oil to the top level of

the tank.

- Drive the figure of eight to check the operation of the steering

control.

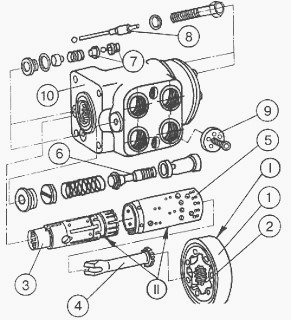

Metering Pump

The metering pump consists of assembly I, distributor II, non-return

valve (9), two anti-hammer valves (7), relief valve (6) and two

anti-vacuum valves (8).

Fig.2. MTZ Belarus Tractor hydraulic steering

1 – stator; 2 – rotor; 3 – spool valve; 4 – power shaft; 5 – sleeve; 6 –

relief valve; 7 – anti-hammer valves; 8 – anti-vacuum valves; 9 –

non-return valve; 10 – body. I – pumping assembly; II – distributor

The Gerotor pumping assembly I consists of the stator (1) fixed on the

body and rotating rotor (2) connected to the spool valve (3) by the

power shaft (4).

The distributor II consists of the body (10),

sleeve (5) and spool valve (3) splined onto the tail-end of the power

shaft of the steering column:

- The relief valve (6) limits the maximum pressure in the pressure

mainline to within 17.5...18.0 MPa (175...180 kgf/cm2) in the hydraulic

power steering system with the double-rod hydraulic cylinder or to

within 14.0...14.5 MPa (140...145 kgf/cm2) in the hydraulic power

steering system with two hydraulic cylinders of steering control.

- The anti-hammer valves (7) limit pressure in the cylinder mainlines at

impact loads.

- The pressure setting of the anti-hammer valves is within 22.5...24.5

MPa (225...245 kgf/cm2).

- The anti-vacuum valves (8) make it possible to ensure the required

supply of the working fluid into the hydraulic cylinder in the emergency

mode and in case of operation of the anti-hammer valves.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader