________________________________________________________________________________

Massey Ferguson 8220 Tractor steering system

The steering system used on Massey Ferguson 8220, 8250 tractors is of

the dynamic type (constant flow rate of 0.5 l/min - standby pressure of

6 bar. There is no

mechanical linkage between the steering wheel and the steering ram.

The Orbitrol type is marked on a plate riveted to the lower part of the

unit (Fig.48). Its control principle is of the ‘Load Sensing’ type.

The MF 8220, 8250 tractors steering system comprises the following main

components:

- a pressurized oil feed from the priority block(s) supplied by the

variable displacement pump,

- an Orbitrol closed centre steering unit, whose capacity differs

according to the tractor type, installed in by-pass (Orbitrol OSPC 125

LS Dynamic 2WD - Orbitrol

OSPC 200 LS Dynamic for 4 WD),

- a double acting ram fitted either on the 4 WD front axle or on the 2

WD axle beam.

The Orbitrol unit is supplied via the priority block(s) by the high flow

rate circuit. When the steering wheel is turned, the necessary flow of

oil is directed to the

corresponding side of the steering ram.

The flowrate in excess, not required by the ram, flows through the

return ports to the selector cover of the Heavy Duty gearbox or to the

righthand side of the Full

Powershift gearbox (according to version).

In the case of an engine

breakdown or failure of the hydraulic pump, the Orbitrol acts as a

hand-operated pump so that the

steering can be controlled.

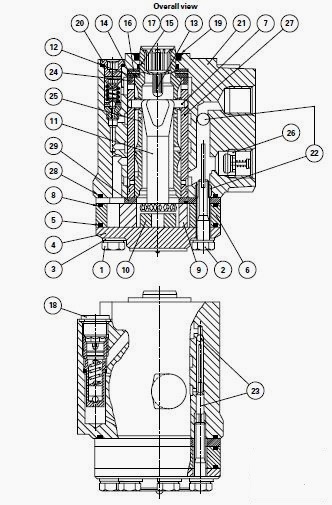

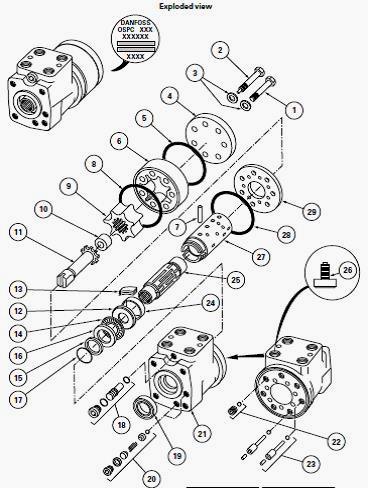

Fig.48/49 Orbitrol OSPC (Parts list)

(1) Bolt, (2) Bolt, (3) O-ring, (4) Cover plate, (5) O-ring, (6) Stator,

(7) Pin, (8) O-ring, (9) Rotor, (10) Spacer, (11) Link shaft, (12)

Washer, (13) Centring springs, (14)

Needle bearing, (15) Bush, (16) Washer, (17) O'ring, (18) Relief-valve,

(19) Seal, (20) Shock valve, (21) Orbitrol unit (distribution valve),

(22) Non-return valve, (23)

Suction valve, (24) Bush, (25) Spool valve, (26) Non-return valve, (27)

Sleeve, (28) O'ring, (29) Distributor plate

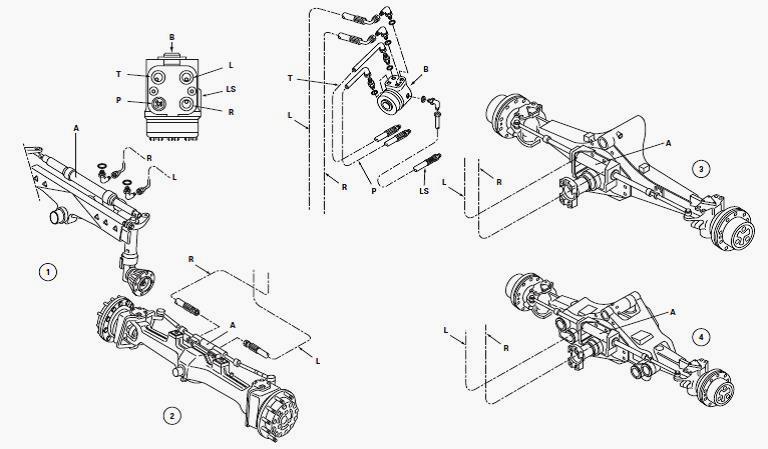

Fig.50. Layout of channels and ports

A - Steering ram, B - Location of steering column, L - Supply to

left-hand side union of the steering ram, LS - Signal to variable

displacement pump via the priority

block(s), P - High flow rate supply from the variable displacement pump,

R - Supply to right-hand side union of the steering ram, T - Return to

the housing via the

selection cover or the gearbox (depending on transmission version), 1 -

2WD axle, 2 - Dana front axle, 3 - Carraro fixed front axle, 4 - Carraro

suspended front axle

Disassembling and reassembling the Orbitrol steering

Disassembly the Massey Ferguson 8220, 8250 steering unit

Remove the distribution valve from the tractor. Place the distribution

valve in a vice fitted with plastic jaws

Take out the bolts (1). Carefully mark the location of the bolt (2) and

then remove it.

Remove the cover plate (4), the O'ring (5), the stator (6) and O'ring

(8).

Remove the spacer (10), the rotor (9), the distribution plate (29) and

the O'ring (28). Take out the splined link shaft (11).

Unscrew the threaded bush and take out the valve ball from the

non-return valve (22).

Take out the two axle pins and valve balls from the suction valves (23)

of the distribution valves.

Extract the sleeve (27) and spool valve (25) assembly by pushing it out

while checking that the pin (7) lies along the horizontal axis.

Remove the washers (12) (16), the needle bearing (14) as well as the

bush (24) from the sleeve and spool valve assembly. Remove the pin (7),

and the centring

springs (13) by pressing on their ends. Separate the sleeve (27) from

the spool valve (25).

Unscrew the plug from the relief-valve (18). Using an 8 mm Allen key,

disassemble the threaded bush and remove the seal, the spring and the

valve (the crimped seat

cannot be removed).

Unscrew the two plugs from the shock valves (20) and remove the seals.

Using a 6 mm Allen key, remove the threaded bushes and take out the

springs, the valve

balls and their seats (the crimped seats cannot be removed).

Extract the seal (19), the bush (15) and the O'ring (17). Disassemble

the non-return valve (26).

Reassembly the MF 8220, 8250 steering unit

Check and clean all components, replace those defective. Lubricate with

clean transmission oil before reassembly.

Reassemble the non-return valve (26). Fit the seal (19), the O'ring (17)

and the bush (15).

Place the valve balls and springs in the recesses of the shock valve

(20). Screw in the threaded bushes, fit the seals and tighten the plugs.

Fit the valve and spring in the recesses of the reliefvalve (18), screw

in the threaded bush. Fit the seal and tighten the plug to a torque of

40 - 60 Nm.

Insert the Massey Ferguson MF 8250, 8220 tractor spool valve (25) into

the sleeve (27). Position the centring springs (13) according to Fig. 48

and insert the pin (7).

Position the bush (24) on the sleeve and spool valve assembly so that

the chamfer facilitates assembly in the steering unit.

Place the washers (12) (16), the chamfer of washer (12) towards the

centring springs (13), by inserting the needle bearing (14) between

them.

Fit the sleeve and spool valve assembly in the steering unit by

oscillating it slightly. Check that the pin (7) is held horizontally.

Place the two valve balls and the two pins in the recesses of the

suction valves (23).

Fit the valve ball in the recess of the non-return valve (22) and screw

in the threaded bush.

Position the splined link shaft (11). Fit the O'ring (28), the

distributor plate (29).

Fit the rotor (9) so that the two concave depressions "C" lie along the

axis of the slot in the splined link shaft (11). Refit the spacer (10).

Place the O'rings (5) (8) on the stator (6).

While avoiding moving the rotor (9), fit the stator (6). Then move it so

that its fixing holes match with those of the steering unit. The rotor

(9) and the pin (7) must be in

the position shown in Figure 50. Refit the cover plate (4).

Refit the bolt (2) (in the same location as marked during disassembly)

and the bolts (1) fitted with their seals (3). Tighten opposing bolts to

a torque of 30 - 35 Nm.

Using a test-bench or a suitable fixture, check the adjustment and

correct operation of the steering unit.

Refit the steering unit on the tractor. Check the oil tightness of the

unions.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader