________________________________________________________________________________

AG250/AG150 transmission - Reassembling the Massey Ferguson 8250 tractor gearbox

- After cleaning the housings and refitting the Massey Ferguson 8250,

8260, 8270 tractor gearbox shafts and clutches, place the rear face of

the rear housing on the suitably sized plank of wood.

- Install the pinion block lifting tool (ATP 3017) on the shafts in

supporting tool (ATP 3019).

- Take care that each shaft is locked to the lifting tool. With a

workshop crane or suitable lifting tackle, move the block of pinions

towards the rear housing.

- Install the plastic guard on the pinion block. Slowly lower the pinion

block into the rear housing taking care that guard remains in place.

- When the pinion block approaches its original position, take care that all the bearings are correctly placed in their respective bores.

- Once the shafts begin to slide into their bores, lightly shake the pinion block so that the bearings slide into the bores.

-

Take care that all the shafts attain their original position. Remove the

pinion block lifting tool.

- Before fitting the seals on the shafts. Reshape each seal ring by

holding it and joining both ends and compressing them so that the ends

overlap. Fit the seals on the

shafts and centre them in the grooves.

- Apply miscible grease on the

outside of the seal to maintain them more easily in the groove. Check

that all the seals are

correctly placed on each shaft.

- Using lifting rings (ATP 3016) fitted to the front housing, lift the

housing to a horizontal position to place it above the shafts of the

rear housing.

- Clean and degrease the front and rear housing flanges. Use Loctite 518

to seal the front and rear housings.

- Install the guide studs (ATP 3022) into the rear housing to facilitate

the installation of the front housing.

- Lower the front housing onto the rear housing. Lightly shake the front

housing shafts, taking care that it is perfectly horizontal when it is

lowered. This avoids

damaging the seal rings when lowering the housing.

- Install the 16 x 140 mm retaining bolts in the housing and tighten

them one by one to a torque of 68 Nm. Then tighten to 135 Nm. Finally

tighten to 217 Nm.

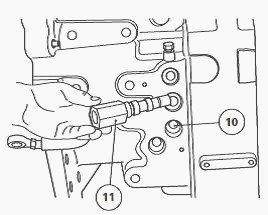

Fig.49

- Install the pressure regulating-valve (11), oil cooler pipe connectors

and the speed and calibration sensors in the housings.

Overhaul a MF 8250, 8260, 8270 tractor speed clutch train

- All speed clutch trains are disassembled in the same manner.

- All speed clutch trains are composed of two clutch packs.

The sets of speed Massey Ferguson 8240, 8250, 8270 tractor clutches are

identified thus:

- clutches A and 2 - 2nd stage shaft

- clutches B and R - 3rd stage shaft

- clutches C and 1 - 4th stage shaft

- For more details on the fitting of each shaft, see the inspection the

transmission components.

- Using a clutch train sling (ATP 3021), remove the speed clutch to be

repaired from the pinion block support tool. Place the clutch train on a

clean workbench and turn

the groove of the seal ring upwards.

Take care that the gear train is properly supported to avoid it toppling

and damaging the pinions.

- Install a split bearing extractor (OEM 4175 or equivalent) on the

bearings. The split bearing extractor must be fitted so that its flat

surface is turned towards the pinion.

-

Tighten the tightening bolts of the extractor until the bearing begins

to extract.

- Hook the pinion extractor below the split bearing extractor and

extract the bearing from the shaft by pulling.

- Remove the circlip from the shaft.

- Place the extractor (ATP 3030) on the pinion and tighten the bolt. To

be able to remove the pinion from the shaft, the extractor must be

tightened around the external

diameter of the pinion.

- In some cases, the main sleeve is necessary and

must be fitted beneath the pinion. Place the extractor by hooking it

beneath the sleeve and

extract the pinions and the bearing from the shaft by pulling.

-

To select the extraction sleeve that matches the pinion, see the pages

relating to the clutch trains.

- Remove circlip, closing plate, thrust plates and friction plates.

- Install a suitable extractor on the bearing of the inside pinions and

remove the latter from the shaft.

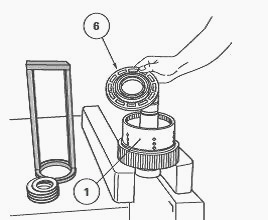

Fig.50

- Place the clutch train in a press. Fit tool ATP 3002 on the Belleville

washers. Compress the washers, remove the circlip and release the

pressure on the washers.

- Remove the Massey Ferguson MF 8250, 8260, 8270 tractor clutch train

from the press and remove the locking washer from circlip (11) and the

Belleville washers

(10).

- Remove the oil seal washer (9) that lies between the Belleville

washers (10) and the clutch piston (6).

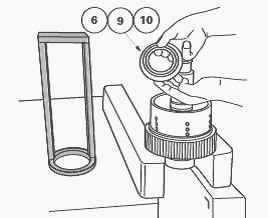

Fig.51

- Once the Belleville washers are removed, inject compressed air into

the clutch oil supply channel near the seal ring on the shaft (24) or

(25). This will eject the piston

from the clutch housing (1).

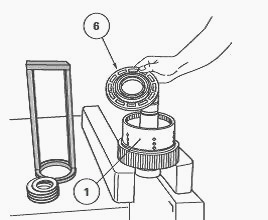

Fig.52

- Disassemble the opposite end of the shaft in the same manner.

The best method to maintain the shaft in a vertical position is to have

a 3” (76 mm) diameter hole in the workbench to recieve the shaft.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader