________________________________________________________________________________

Repair of AG150/AG250 transmission – Disassembling the MF 8280 tractor powershift gearbox

The Massey Ferguson 8220, 8210, 8280 tractor is equipped of John Deere

AG150/AG250 transmission.

- Separate the tractor between the gearbox and the intermediate housing.

- Separate the gearbox from the engine.

Disassembling the Powershift gearbox

- Separate the tractor between the gearbox and the intermediate housing.

- Separate the gearbox from the engine.

- Take off the Gerotor pump from the gearbox and PTO shaft from the rear

of the gearbox. The Gerotor pump is fixed to the rear housing of the

gearbox by six bolts. Slide the pump and shaft apart to separate them.

Keep the O’rings between the pump and the rear housing.

- Remove the MF 8280, 8210, 8220 tractor engine speed sensors, forward

speed sensor and the calibration sensor from the gearbox in order to

avoid damage to them when separating the housings.

- Remove the hydraulic supply pipes, the output connections to the oil

cooler and the pressure regulating-valve from the front housing of the

gearbox in order to gain access to the housing bolts.

- Place a wooden plank of the correct thickness on the ground. Provide

enough space in order to be able to reach the top of the gearbox with

workshop crane or a suitably adapted lifting tackle.

- In order to protect the mating faces from scratching or damage, before

removing the front housing, position the gearbox vertically using a

suitable sling and lifting rings ATP 3016, the rear face being placed on

the wooden plank.

Removing the front housing

Raise the front housing after having removed the bolts.

Adjust the lifting sling in such a way that the front housing remains

horizontal during the separating operation. The shafts will be withdrawn

more easily from the housing if the latter is shaken lightly as it is

lifted.

Take care that the transmission shafts remain in the rear housing and

are not lifted at the same time as the front housing. Lightly shake the

front housing when it is lifted to avoid bending the shafts.

Removing Massey Ferguson 8280, 8210,

8220 tractor clutches and transmission Shafts

Clean the work area and prepare shaft support plate (ATP 3019) on which

the work will be carried out. The workshop must be accessible by a

workshop crane or suitable lifting tackle.

John Deere AG150 transmission gearbox - Stands screwed directly into the

plate

AG 250 transmission gearbox - Stands screwed into the bushes

- Remove the seal rings from all shafts to avoid damaging them before

installing the shaft-lifting tool.

- Install lifting tool (AP 3017) on the shafts and fix each shaft to the

tool with the supplied locking devices.

Place the lifting ring of the tool in the correct position.

- AG 150 transmission gearbox

- John Deere AG250 transmission gearbox

- With a workshop crane or suitable lifting tackle and a chain attached

to the lifting ring of the tool.

- Gently raise, while lightly shaking the shafts so that the bearings

leave the bores of the rear housing. Take care not to lift the rear

housing at the same time in order to avoid bending the shafts.

- Once the block of shafts has been removed, take off the plastic guard

from the forward pinions.

- lace the tool and shafts in a single block on the workbench.

- Position the block of removed shafts on the previously prepared

support (ATP 3019).

- Remove the shaft lifting tool after having positioned the shafts on

the support. Take care not to knock over the block of shafts or clutches

when removing the lifting tool.

- Mark the location of the shafts in order to understand how to

reassemble them.

- The shafts may be removed one by one from the support to carry out

even greater levels of disassembly.

- For the repair of clutches and shafts.

Replacing the input shaft seal

Replacing the seal only without disassembling the MF 8280, 8210, 8220

tractor gearbox

Fig.46

- Separate the Massey Ferguson 8280, 8210, 8220 tractor between the

engine and gearbox.

- Take out, by sliding them, the input shaft and the spring from the

gearbox.

- Take out the input shaft seal through the front housing of the gearbox

using a suitable extractor.

- Install a new seal using an insertion sleeve.

- Take care that the new seal is correctly aligned so that it does not

leak. Lubricate the seal lip with miscible grease.

- Reassemble in reverse order using the guide studs to align the gearbox

with the engine.

Replacing the seal while disassembling the MF

8220, 8210, 8220 tractor gearbox

Fig.47

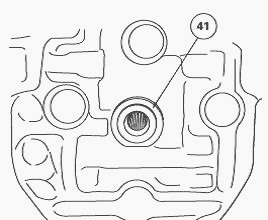

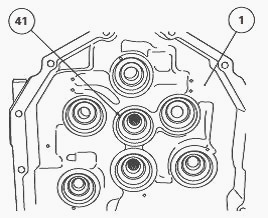

- When the front housing (1) has been removed, take out the old seal

(41).

- Install the new seal using a suitable insertion sleeve, taking care

that it is correctly aligned so that it does not leak. Lubricate the

seal lip with miscible grease.

Inspecting and repairing the housing

Inspecting the housing

- Examine all the bearing bores of the front and rear housings to ensure

that they are not damaged. Replace or repair any damaged bores.

- Examine all wear rings for damage and replace where necessary.

Fig.48

Replacing seal wear rings

All the seal bores in the front housing contain rings. The latter may be

replaced if they are damaged. The location of the holes in the rings is

not very important since the bores have annular grooves beneath all the

bushes.

By using an extractor with two or three jaws and fitted with an inertia

device, hook the front edge of the ring and extract it. Fit a new ring

leaving the chamfer on the outside to guide the seal. Fit the new bush

by pressing the insertion sleeve against the housing.

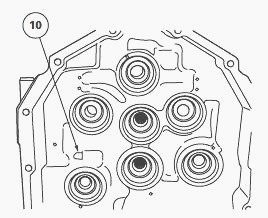

Lubricating relief-valve

If the previous tests have shown that the lubricating relief-valve is

defective (10), it may be removed from the interior at this time. It may

also be removed from outside the housing by taking off the oil cooler

piping and connection. Screw tap the inside of the valve (10) (Fig. 26)

and use an inertia extractor to remove it.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

SPECS

SPECS LOADERS

LOADERS MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS MF 1523

MF 1523 MF 1531

MF 1531 MF 135

MF 135 MF 1547

MF 1547 MF 1635

MF 1635 231

231 231S

231S 235

235 240

240 241

241 255

255 265

265 274

274 285

285 375

375 916X Loader

916X Loader 921X Loader

921X Loader 926X Loader

926X Loader 931X Loader

931X Loader 936X Loader

936X Loader 941X Loader

941X Loader 946X Loader

946X Loader 951X Loader

951X Loader 956X Loader

956X Loader 988 Loader

988 Loader 1655

1655 GS1705

GS1705 1742

1742 2635

2635 4608

4608 1080

1080 1100

1100 2615

2615 3050

3050 3060

3060 4708

4708 5455

5455 5450

5450 5610

5610 5613

5613 DL95 Loader

DL95 Loader DL100 Loader

DL100 Loader DL120 Loader

DL120 Loader DL125 Loader

DL125 Loader DL130 Loader

DL130 Loader DL135 Loader

DL135 Loader DL250 Loader

DL250 Loader DL260 Loader

DL260 Loader L90 Loader

L90 Loader L100 Loader

L100 Loader 6499

6499 7480

7480 7618

7618 7726

7726 1533

1533 2604H

2604H 2607H

2607H 4455

4455 4610M

4610M 4710

4710 L105E Loader

L105E Loader L210 Loader

L210 Loader 1014 Loader

1014 Loader 1016 Loader

1016 Loader 1462 Loader

1462 Loader 1525 Loader

1525 Loader 1530 Loader

1530 Loader 232 Loader

232 Loader 838 Loader

838 Loader 848 Loader

848 Loader 5712SL

5712SL 6713

6713 6715S

6715S 7475

7475 7615

7615 7716

7716 7724

7724 8240

8240 8650

8650 8732

8732 246 Loader

246 Loader 1036 Loader

1036 Loader 1038 Loader

1038 Loader 1080 Loader

1080 Loader 856 Loader

856 Loader