________________________________________________________________________________

Kubota B2410, B2710, B2910, B7800 - HST Transmission

Kubota B2410, B2710, B2910, B7800 -

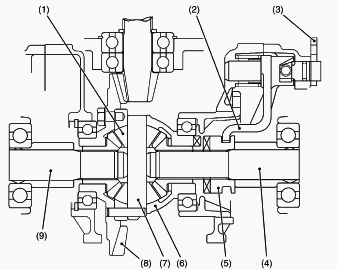

Hydrostatic Transmission System

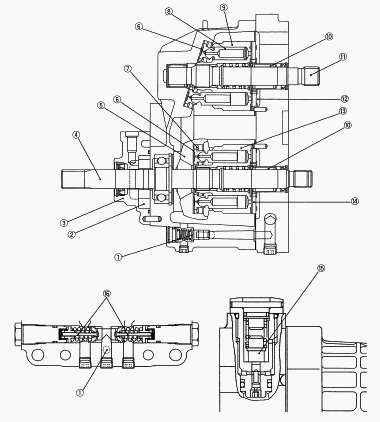

1 - Charge Relief Valve, 2 - Charge Pump, 3 - Charge Pump Case, 4 - Pump

Shaft, 5 - Variable Swashplate, 6 - Thrust Collar, 7 - Retainer Plate, 8

- Piston, 9 - Cylinder Block (Motor), 10 - Needle Bearing, 11 - Motor

Shaft, 12 - Valve Plate (Motor), 13 - Cylinder Block (Pump), 14 - Valve

Plate (Pump), 15 - Neutral Valve, 16 - Check and High Pressure Relief

Valve

Check and High Pressure Relief Valve

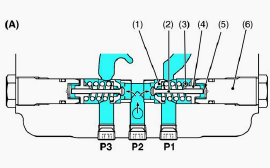

The check and high-pressure relief valve consists of pressure poppet,

check valve seat, relief valve spring, spring guide and check valve

spring. The valve is used to prevent an overload that would happen at a

quick start, sudden stop or even during usual running. This valve

doubles as a check valve. The check and high-pressure relief valves are

laid out facing each other as shown in the figure.

In neutral, both valves are open and charging oil enters into the main

oil circuit through the valves.

A - In Neutral (Stop): 1 - Check Valve Seat, 2 - Pressure Poppet, 3 -

Relief Valve Spring, 4 - Spring Guide, 5 - Check Valve Spring, 6 - Valve

Plug

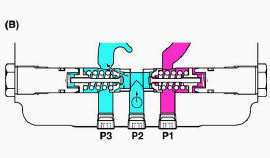

At normal operation, the check valve in the high pressure side is closed

and it pushes and opens the another one. An excessive charge flow goes

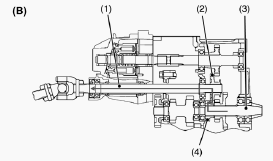

through the charge relief valve into HST housing (B).

B - When Check Valve Activating (Normal Operation)

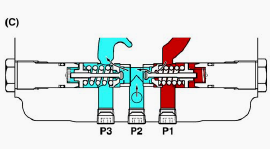

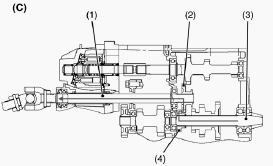

The check and high-pressure relief valve along the high-pressure line

serves as a high-pressure relief valve. If the pressure exceeds a

high-pressure limit level, the pressure poppet opens itself against the

relief valve spring (3) force and opens the valve seat that is located

between the check valve seat (1) and the pressure poppet (2). Now the

flow goes from P1 to P2 and P3 (C).

C - When High Pressure Relief Valve Activating

If the P1 pressure drops, the relief valve spring forces the valve seat

closed against the pressure. The high pressure oil at P1 does not flow

to P2 any longer. As discussed above, the check and high-pressure relief

valve protects engines, pumps, motors, gears and even the machine itself

from overload.

Front Wheel Drive System

B2410: 1 - Front Wheel Drive Shaft, 2 - Shifter Gear 20T, 3 - Spiral

Bevel Pinion Shaft, 4 - Gear 13T

B2710, B2910, B7800: 1 - Front Wheel Drive Shaft, 2 - Shifter Gear 19T,

3 - Spiral Bevel Pinion Shaft, 4 - Gear 14T

2-wheel drive or 4-wheel drive is selected by changing the position of

shifter gear (2) with the front wheel drive lever. When the front wheel

drive lever is set to “Disengaged”, the shifter gear (2) is neutral and

power is not transmitted to the front wheel drive shaft (1). When the

front wheel drive lever is set to “Engaged”, the shifter gear (2) slides

to the right to engage with gear (4) on the spiral bevel pinion shaft

(3). Therefore, the front drive shaft is actuated to drive the front

wheels.

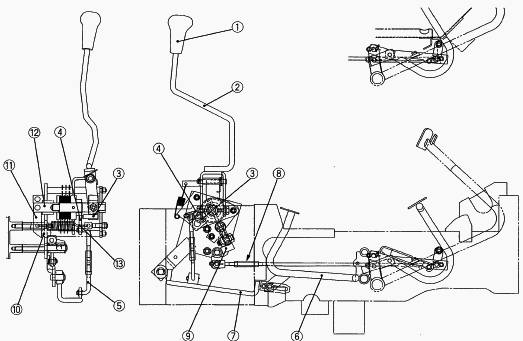

Kubota B2910, B7800 Hydrostatic Transmission - Cruise Control

Cruise Control Linkage

1 - Grip, 2 - Cruise Control Lever, 3 - Lever Pin, 4 - Cruise Control

Arm, 5 - Cruise Control Rod, 6 - HST Pedal, 7 - HST Pedal Lever, 8 - HST

Release Rod, 9 - Release Lever 1, 10 - Release Lever 2, 11 - Release

Arm, 12 - Cruise Control Shaft, 13 - Spring

Tilt the cruise control lever (2) to the right, and the lever pin (3) is

activated to lift the cruise control arm (4). Move the above lever

forward, and the HST pedal lever (7) rises by the cruise control rod (5)

that is coupled with the cruise control arm (4) (The HST pedal (6) is

now in the depressed position). Now the cruise control lever (2) can be

fixed (set) to a desired position through the disc (friction) and the

plate under spring (13) force. With the cruise control lever (2) set at

the center on the lever guide, the HST pedal (6) is given an allowance

by the oval hole of the HST pedal lever (7). This pedal can be stepped

further down by this allowance (This means that the machine speed can be

accelerated from a setting and that when the HST pedal is released, the

machine speed comes down to the setting).

Cruise Control Release System

This is release system of the cruise the cruise control back to neutral

automatically when brake pedals are depressed. Cruise control lever is

set with plate, friction disc by the cruise control shaft, release arm

and spring. When brake pedals are depressed, brake link pull the HST

release rod, release lever 1 and release lever 2. Afterwards, cruise

control shaft is pulled though release arm. As a result, the holding

force of cruise control lever is lost. And, cruise control lever returns

to neutrality by force of the spring and the return force of HST.

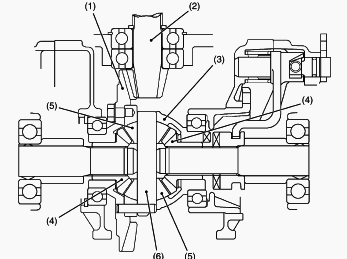

Kubota B2410, B2710, B2910, B7800 - Differential Gear

1 - Spiral Bevel Gear, 2 - Spiral Bevel Pinion, 3 - Differential Gear

Case, 4 - Differential Side Gear, 5 - Differential Pinion, 6 -

Differential Pinion Shaft

The differential gear assembly is a mechanism to provide smooth

steering. It automatically provides different optimum torques to the

right and left wheels according to road resistance and braking friction

at the wheels. The differential gear assembly is composed of the

differential case, differential pinions, differential side gears,

differential pinion shaft, spiral bevel gear, etc.

Differential Lock: 1 - Differential Pinion, 2 - Shift Fork, 3 -

Differential Lock Lever, 4 - Differential Gear Shaft, 5 - Differential

Lock Clutch, 6 - Differential Case, 7 - Differential Pinion Shaft, 8 -

Spiral Bevel Gear, 9 - Differential Gear Shaft

Kubota B2410, B2710, B2910, B7800 Differential Troubleshooting

Problem - Excessive or Unusual Noise at All Time

Improper backlash between spiral bevel pinion and bevel gear - Adjust.

Improper backlash between differential pinion and differential side gear

- Adjust.

Bearing worn - Replace.

Insufficient or improper type of transmission fluid used - Replenish or

replace.

Problem - Noise while Turning

Differential pinions or differential side gears worn or damaged -

Replace.

Differential lock binding (does not disengage) - Replace.

Bearing worn - Replace.

Problem - Differential Lock Can Not Be Set

Differential lock shift fork damaged - Replace.

Differential lock shifter mounting pin damaged - Replace.

Differential lock clutch damaged - Replace.

Problem - Differential Lock Pedal Does Not Return

Differential lock pedal return spring weaken or damaged - Replace.

Differential lock fork shaft rusted - Repair.

Kubota B2410, B2710, B2910, B7800 Tractor - Separating Engine from Clutch

Housing

Draining Transmission Fluid

Place oil pan underneath the transmission case, and remove the drain

plugs.

Drain the transmission fluid.

Reinstall the drain plug.

Fill new oil from filling port after removing the filling plug up to the

upper notch on the dipstick.

After running the engine for few minutes, stop it and check the oil

level again, if low, add oil prescribed level.

Transmission fluid capacity:

B2410 - 12.5 L, B2710 - 15.5 L,

B2910, B7800 - 14.5 L.

Hood, Side Cover and Battery Cord

Open the hood and remove the front grille. Disconnect the battery

grounding cord. Disconnect the head light connectors and remove the hood

and side covers. When disconnecting the battery cords, disconnect the

grounding cord first. When connecting, positive cord first.

Steering Wheel

Remove the steering wheel cap. Remove the steering wheel mounting nut

and remove the steering wheel with a steering wheel puller

Meter Panel and Panel Under Cover

Open the meter panel and disconnect the meter panel connector and

hour-meter cable. Then remove the meter panel. Disconnect the

combination switch connector, main switch connector, hazard switch

connector and position light switch connector. Tap out the spring pin

and remove the hand accelerator lever. Remove the panel under cover.

Fuel Tank

Disconnect the fuel hose at the fuel filter side, then drain fuel

completely. Remove the fuel tank frame stay. Disconnect the hazard unit,

starter relay and regulator connectors and remove the lead wire for fuel

gauge. Remove the fuse box. Disconnect the overflow hoses of fuel line.

Remove the tank frame with fuel tank. Disconnect the hydraulic pipes and

remove the battery stay with oil cooler. Disconnect the 2P connector and

remove the engine stop solenoid. Apply a thin coat of liquid gasket to

both surface of the engine stop solenoid.

Bi-speed Turn Cable (Bi-speed Model)

Remove the spring lock pin and loosen the lock nuts and then remove the

bi-speed turn cable.

Propeller Shaft Cover and Coupling

Loosen the clamp and slide the propeller shaft cover to the rear. Tap

out the spring pin and then slide the coupling to the rear. Apply grease

to the splines of the propeller shaft and coupling.

Universal Joint and Bearing Holder

Loosen the clamp and slide the universal joint cover to the rear. Tap

out the spring pins and then slide the universal joint to the rear.

Remove the bearing holder with propeller shaft and universal joint.

Apply grease to the splines of the propeller shaft and universal joint.

Drag Link

Remove the cotter pin and loosen the slotted nut. Disconnect the drag

link with a tie-rod end lifter from the knuckle arm.

Separating the Engine from Clutch Housing

Remove the power steering delivery pipe. Disconnect the accelerator rod.

Disconnect the three point hitch delivery pipe and suction hose at the

hydraulic pump. Disconnect the glow plug lead wire and thermo sensor

lead wire. And then disconnect the connector for alternator and starter

motor lead wire. Place the jack under the center frame. Hoist the engine

by the chain at the engine hook. Remove the engine mounting screws and

separate the engine from the clutch housing.

Kubota B2410, B2710, B2910, B7800 - Hydrostatic Transmission Adjusting

Adjusting Maximum Speed

Shorten the stopper bolt front to the position where the length of the

bolt is not touched to the HST pedal (1) even if the HST pedal is fully

depressed forward. Lengthen the length of the stopper bolt front

gradually with the HST pedal fully depressed and lengthen the one turn

from the position where the head of the stopper bolt touches the HST

pedal. Tighten the lock nut. Adjust the length of stopper bolt rear to

27 to 28 mm (1.06 to 1.10 in.).

Maximum speed with turf tire (Forward)

B2410 - 21.1 to 22.1 km/h (13.2 to 13.8 mph).

B2710, B2910, B7800 - 23.5 to 24.5 km/h (14.7 to 15.3 mph).

Maximum speed with turf tire (Reverse)

B2410 - 16.8 to 17.8 km/h (10.5 to 11.1 mph).

B2710, B2910, B7800 - 18.7 to 19.7 km/h (11.7 to 12.3 mph).

Adjusting Cruise Control Linkage

With the cruise control lever at the N position on the lever guide,

check for a gap between the lever pin and the cruise control arm. Adjust

the cruise control rod, when required, to leave no gap between them. At

the same time, make sure that there is no gap between the rear end of

the oval hole of the HST pedal lever and the pin of the HST pedal.

Finally step down the HST pedal all the way to make sure that the cruise

control lever can hold the HST pedal in place.

Adjusting Cruise Control Release Linkage

Adjust the brake pedals play first. Then adjust the HST release rod

turnbuckle to allow no gap between the release levers 1 and 2 as well as

between the release lever 2 and the release rod. Now step on one of the

brake pedals to make sure the cruise control is not released. Also step

on both the brake pedals coupled together to make sure that the cruise

control is released.

Cruise Control Lever

After adjusting the cruise control linkage, measure the force to move

the cruise control lever forward at its top (grip). If the force is not

within the factory specifications, loosen the lock nut and turn the nut

to adjust. Retighten the lock nut securely.

Kubota B2410, B2710, B2910, B7800 Tractor - Transmission Case

Neutral Holder and Neutral Holder Arm

Place parting marks on the neutral adjuster and the neutral holder arm.

Remove the neutral holder arm with neutral adjuster. Remove the screw

and pull out the neutral holder. Align the parting marks and install the

neutral adjuster and the neutral holder arm.

Charge Pump

Remove the charge pump mounting screws, and remove the charge pump

assembly from the HST housing. Take care not to damage the O-ring.

14T Gear -

Remove the external snap ring and draw out the 14T gear.

Center Section

Remove the center section mounting hex. socket head screws. Tap the

front of center section flange with a soft hammer and separate the

center section from HST housing. Cover the splines of each shaft with

thin tape to protect sealing lip. Install center section with gasket,

O-ring and valve plates in place. Valve plates may stick to the center

section but they are not fixed. Take care not to drop them. Valve plates

are not interchangeable. Valve plate of pump has two notches and the one

of motor has no.

Motor Cylinder Block and Pump Cylinder Block

Pull out the output shaft and motor cylinder block with pistons as a

unit. Slide out the pump cylinder block with pistons.

4th Gear Shaft and Spiral Bevel Pinion Shaft

Remove the spiral bevel pinion shaft with 15T-29T (B2410) or 16T-27T-32T

shifter gear, 13T (B2410) or 14T gear and shift fork. Remove the 4th

gear shaft. When installing the spiral bevel pinion shaft, be sure to

install the shims. When disassembling the spiral bevel pinion shaft, be

sure to replace the external snap ring with new one.

Bearing Holder

Remove the external snap ring and remove the 27T gear. Remove the

bearing holder mounting screws and remove the bearing holder.

2nd Gear Shaft and Middle Shaft

Remove the 2nd gear shaft with bearings. Remove the 3rd shaft assembly

and shift fork with shift rod. Remove the middle shaft and 19T gear with

bearing. When assembling the 19T gear, face the chamfer side to the

rear.

Front Wheel Drive Shaft -

Remove the external snap ring and remove the 20T shifter gear. Draw out

the front wheel drive shaft to the front.

Mid-PTO Shaft

Remove the spring and ball. Draw out the dowel pin and remove the shift

arm with shifter. Remove the oil seal and internal snap ring. Remove the

mid-PTO shaft with 11T shifter gear and bearings. Apply grease to lip

and outer of oil seal.

Kubota B2410, B2710, B2910, B7800 - Hydrostatic Transmission Service

Charge Pump

Check the charge pump housing and the gerotor assembly for scratches and

wear. If scratch or worn, replace the charge pump complete assembly.

Input Shaft

Pull out the input shaft from the case. Check the seal surface, the

bearing surface and the bearing. If the shaft is rough or grooved,

replace. If the bearing is worn, replace.

Cylinder Block Bore and Pistons

Lift all the pistons gently with the retainer plate. Check the pistons

for their free movement in the cylinder block bores. If the piston or

the cylinder block bore is scored, replace cylinder block assembly. Do

not interchange pistons between pump and motor cylinder block. Pistons

and cylinder blocks are matched. Clearance between piston and bore -

0.02 mm (0.0008 in).

Piston Slipper and Retainer Plate

Check the slipper for flatness. If rounded, replace Measure the

thickness of piston slipper. If the measurement is less than the

allowable limit, replace. Check the lubricant hole for clogging.

Thickness of slipper - 3.00 mm (0.118 in).

Cylinder Block Face

Check the polished face of cylinder block for scoring. If scored,

replace cylinder block assembly. Check the spring for breakage. If

broken, replace cylinder block assembly.

Transmission Case

Checking Bearing

Hold the inner race, and push and pull the outer race in all directions

to check for wear and roughness. Apply transmission fluid to the

bearing, and hold the inner race. Then, turn the outer race to check

rotation. If there is any defect, replace it.

Clearance between Shift Fork and Shift Gear Groove

Insert the fork into the shift gear groove and measure the clearance

with a feeler gauge. If the clearance exceeds the allowable limit,

replace it. Clearance between shift fork and shift gear groove - 0.10 to

0.35 mm (0.004 to 0.014 in).

Clearance between 13T Gear and 3rd Shaft

Measure the 13T gear I.D. with an inside micrometer, and then 3rd shaft

O.D. with an outside micrometer. Measure the O.D. of two needles in the

needle bearing with an outside micrometer. Clearance is the difference

between the gear I.D. and the sum of shaft O.D. and two needle O.D. If

the clearance exceeds the allowable limit, replace it. Clearance between

13T gear and 3rd shaft - 0.007 to 0.046 mm (0.00028 to 0.00181 in). 3rd

shaft O.D. - 21.987 to 22.000 mm (0.86562 to 0.86614 in). 13T gear I.D.

- 30.007 to 30.021 mm (1.18138 to 1.18193 in). Needle O.D. - 3.994 to

4.000 mm (0.15724 to 0.15748 in).

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605