________________________________________________________________________________

Kubota B6000, B7000, B7001 - Transmission

Kubota B6000, B7000, B7001 Tractor - Clutch

Adjustments

Adjustment of clutch pedal

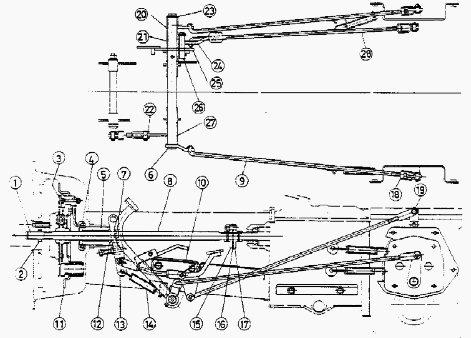

1 - Bearing, 2 - Oil Sea, 3 - Clutch Disc Assy, 4 - Thrust Ball Bearing,

5 - Bearing Holder, 6 - Brake Pedal Shaft, 7 - Clutch Release Fork, 8 -

Propeller Shaft, 9 - Brake Rod, 10 - Step, 11 - Pressure Plate, 12 -

Ring, 13 - Clutch Rod, 14 - Spring, 15 - Flange, 16 - Rubber, 17 - Pin

Flange, 18 - U-Joint, 19 - Differential Lock Lever, 20 - Brake RH Pedal,

21 - Brake LH Pedal, 22 - Rod, 23 - Collar, 24 - Differential Lock

Pedal, 25 - Spring, 26 - Differential Lock Pedal Shaft, 27 - Clutch

Pedal, 28 - Differential Lock Rod

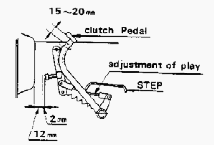

Adjustment of clutch pedal play

The play of the clutch pedal is governed by the clearance between the

release lever and the ball bearing. The clearance has been set to 0 098

to 0.12 in (2.5 to 3 mm) before the tractor left the factory. However,

me clearance changes as the tractor is used. The general tendency is for

the play to increase at the beginning but will decrease with use. if the

clutch pedal were to be used with no play, it would cause troubles. Be

sure to make checks at time of routine checks and maintenance, and if

necessary, make the necessary adjustment.

Precaution in operating clutch

Clutch should serve to transmit power without loss and furthermore

should engage or disengage accurately whenever so required. For this

reason, operation and maintenance services should be performed very

carefully. The clutch pedal should be depressed speedily to disengage

the clutch arid returned slowly to reengage it. Retrain by all means

from leaving the foot on the pedal while operating the tractor or from

traveling with clutch half engaged. Kubota B6000, B7000, B7001 tractor

should not be jerked with a load more than the specified not be used for

long period with overload, because otherwise the life of the clutch will

be shortened or various troubles may likely be caused, in case of long

storage, keep the clutch disengaged by using a piece of wood to lock the

pedal. Engine starting is only possible when the clutch is disengaged.

Kubota B6000, B7000, B7001 Tractor -

Transmission Assembly

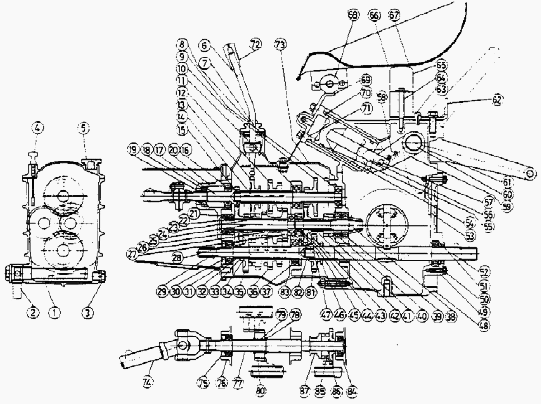

Kubota B6000, B7000, B7001 Transmission Parts: 1 - Oil

Filter, 2 - Pipe, 3 - Plug, 4 - Oil Gauge, 5 - Cap, 6 - Change Lever, 7

- Spring, 8 - Cover, 9 - Ball Bearing, 10 - 13T-28T Gear, 11 - Ball

Bearing, 12 - 20T-25T Gear, 13 - 29T Gear, 14 - 4th Shaft, 15 - Needle

Bearing, 16 - Ball Bearing, 17 - 1st Shaft, 18 - Ball Bearing, 19 - Oil

Seal, 20 - 1st Shaft Cover, 21 - Ball Bearing, 22 - Collar, 23 - Collar,

24 - 2nd Shaft, 25 - 14T Gear, 26 - 18T Gear, 27 - 23T Gear, 28 - 30T

Gear, 29 - 3rd Shaft, 30 - Oil Seal, 31 - Ball Bearing, 32 - Collar, 33

- Thrust Collar, 34 - Bush, 35 - 29T Gear, 36 - 20T-25T Gear, 37 - Ball

Bearing, 38 - Spiral Bevel Gear Pinion, 39 - Ball Bearing, 40 - Ball

Bearing, 41 - 15T Gear, 42 - Collar, 43 - 30T Gear, 44 - Ball Bearing,

45 - Bush, 46 - Collar, 47 - Ball Bearing, 48 - Differential Gear Case,

49 - 5th Shaft Cover, 50 - Ball Bearing, 51 - Oil Seal, 52 - 5th Shaft,

53 - Plate, 54 - O-Ring, 55 - Oil Pressure Piston, 56 - Oil Pressure

Piston Rod, 57 - Arm Pin, 58 - Lock Washer, 59 - Oil Pressure Arm, 60 -

Oil Pressure Arm Shaft, 61 - Case Rear Cover, 62 - Washer, 63 -

Breather, 64 - Collar, 65 - Seat Rear Support, 66 - Seat, 67 - Seat

Cover, 68 - Cushion, 69 - Seat Front Support, 70 - O-Ring, 71 - Cylinder

Cap, 72 - Lever Grip, 73 - Case Front Cover, 74 - Front Axle Drive

Shaft, 75 - Oil Seal, 76 - Ball Bearing, 77 - Reverse Shaft, 78 - 1st

Shaft Collar, 79 - Bush, 80 - 22T Gear, 81 - 28T Gear, 82 - Bush, 83 -

Transmission Case, 84 - Ball Bearing, 85 - 1st Shaft Collar, 86 - 25T

Gear, 87 - Front Wheel Drive Clutch

Kubota B6000, B7000, B7001 - Transmission case

disassembly

Drain out the oil from the right and left bottom of the differential

gear case and bottom of the transmission case. Remove front and rear

case cover. Remove left and right axle case, and draw out differential

gear shaft, differential gear lock fork and axle. Pull out 5th shaft.

Unscrew the bolts connecting transmission case and differential gear

case and divide the cases. Remove 28T gear, shift fork, and shift fork

rod. Pull out spiral bevel gear pinion. Pull out 25T gear on rear end of

back shaft and the ratchet clutch. Remove the auxiliary speed change

shift fork. Remove the 1st shaft cover and pull out the 1st shaft.

Needle bearing and collar are in the 1st shaft so be careful that they

do not drop out. Remove the 4th shaft to the back. Pull out the reverse

shaft. Pull out the 2nd shaft to the front. Pull out the 3rd shaft to

the back. Pull out the rotary speed change shift fork.

Kubota B6000, B7000, B7001 - Transmission case

assembly

Assemble the rotary speed change lever, auxiliary speed change lever and

front axle drive clutch lever. Assemble the 3rd shaft (The front and

back thrust collar for the 29T gear should be assembled so that the side

with notches faces the gear side). Assemble the rotary speed change

shift fork and the shift rod. The shift rod should be assembled with the

O-ring groove in the front side. Push in from the front, being very

careful net to drop the balls. Assemble the 2nd shaft. Assemble the

reverse shaft. The front and back collar for the 25T gear at the rear

part of the reverse shaft should be assembled so that the side with the

notches face the gear side. The 22T gear should be assembled with the

chamber part in the front. Assemble the 4th shaft.

Assemble the 1st shaft and 1st shaft cover. Knock in the 6202 bearing of

the 2nd shaft and 4th shaft. Assemble the auxiliary speed change shift

fork and shift fork shaft. The shift fork shaft is symmetrical so there

is no right or left side to the shaft. Assemble the spiral level gear

pinion. Assemble with the gear and bearing in the assembled condition.

Assemble the 28T gear, shift fork and shift rod. Assemble at the front

and of the shift rod of the 28T gear which is engaged with the 5th

shaft, and engage on the spline of the 3rd shaft. Assemble the

differential in the differential case. In ordinary cases 1 shim each is

inserted on the outer side of the right and left bearing of the

differential assembly. Assemble the differential gear case to the

transmission case. Check the engagement of the differential bevel gear

and the backlash. The backlash should be 0.13-0.25 mm. Assemble the 5th

shaft. Insert from the rear end of the differential gear case, turn and

engage to the spline of the 28T gear Put on the cover.

Assemble the axle and the differential gear. First put in the axle and

then put in the differential gear shafts. At the same time, put on the

differential lock fork and the fork rod on the right side. Assemble the

axle cover and lower link bracket. Operate the differential lock to

check whether it operates correctly. Assemble the front and rear case

covers. At the time of assembling the front case cover, put the main

speed change gear to neutral, and check to make sure that the fork of

the main speed change shift rests in the fork groove of the gear and

works correctly.

Also be sure that the auxiliary speed change lever is

positioned correctly on the auxiliary speed charge fork groove. After

tightening the cover bolts, check to see whether the main speed change

lever and auxiliary speed charge lever works property. When the

hydraulic arm has been disassembled, be sure to align the assembly mark

of the hydraulic arm shaft and the hydraulic arm at the time of

assembly. When assembling the lift arm, be sure to align correctly. Do

not remove check rod and operate the hydraulic arm. The hydraulic arm

will hit the rear part of the differential gear case and might damage

the case.

Kubota B6000, B7000, B7001 - Adjustment of

spiral bevel pinion and gear

Adjustment of the spiral bevel pinion and gear is effected by shims used

on the differential bearing cases. At the time of disassembly, be

attentive to the shims used there and be careful not to lose them. In

assembling, return the unassembled shims to their original places, and

then check meshing and backlash of the gear teeth. If both are correct,

proceed with assembly. However, if a tractor has been put to a long

period of service, it generally requires an adjustment in this unit,

which should be made in the following order. Adjustment in clearance of

differential complete, to differential bearing cases.

Since the differential is supported on the right and left by ball bearings, and improper adjustment in shims used on the bearing cases will result in a differential which is too tight to turn smoothly or which rattles to right and left not allowing the pinion and gear to mesh properly. For correcting such troubles, gradually decrease in the former case and increase in the latter case the number of shims on bearing cases until the differential complete turn lightly. For easier adjustment, it is recommended that me spiral bevel pinion shaft be removed from the assembly during the service. After the above shim adjustment, attend to the following adjustment.

Adjustment in backlash and meshing of spiral

bevel pinion and gear. This adjustment is very important. Whether this

has been performed correctly or not seriously affects the life of the

gears and consequently the durability of the tractor. Therefore, make

the adjustment with close care. Simple ways of judging the results of

adjustment are: Backlash - Fill and impress solder between teeth meshed

and measure the thickness of impressed solder with a micrometer. If the

measurement is 0.1 to 0.2 mm), the adjustment is correct. Contact of

teeth - Apply a very thin coat of rod thinned with oil to contact

surfaces of several teeth of the pinion. Mesh and turn the pinion with

the gear lightly.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605