________________________________________________________________________________

Kubota BX2200, BX2230, BX2350, BX22 - Transmission

Kubota BX2200, BX2230, BX2350, BX22 -

Hydrostatic Transmission

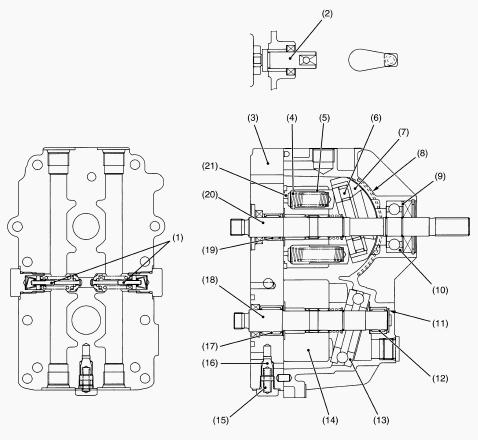

1 - Check and High Pressure Relief Valve, 2 - Trunnion Arm, 3 - Center

Unit, 4 - Piston Spring, 5 - Piston, 6 - Thrust Roller Bearing, 7 -

Swashplate, 8 - Cradle Bearing, 9 - Spacer, 10 - Ball Bearing, 11 -

Thrust Washer, 12 - Needle Bearing, 13 - Thrust Ball Bearing, 14 -

Cylinder Block (Motor), 15 - Charge Relief Spring, 16 - Charge Relief

Valve, 17 - Needle Bearing, 18 - Motor Shaft, 19 - Needle Bearing, 20 -

Pump Shaft, 21 - Cylinder Block (Pump)

Pump and Motor

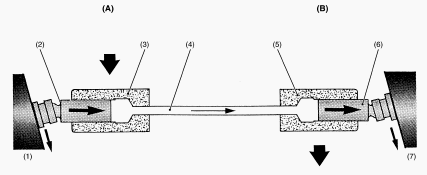

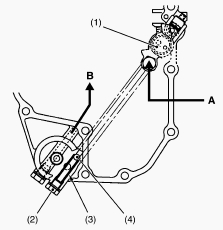

1 - Swashplate, 2 - Piston, 3 - Cylinder, 4 - Oil, 5 - Cylinder, 6 -

Piston, 7 - Swashplate, A - Pump, B - Motor

The hydrostatic transmission consists of variable displacement piston

pump, fixed displacement piston motor and valve system. Pump and motor

cylinder, each containing pistons, are connected by lines. Cylinders and

lines are filled with oil. Pistons ride against swashplates (1) and (7)

located in pump (A) and motor (B). In the pump (A), as the cylinder (3)

rotates, pistons (2) move across the sloping face of swashplate (1) and

slide in or out of their cylinder bores. The oil (4), forced out by the

pump pistons (2), causes the motor pistons (6) to slide out of their

cylinder bores. In the motor (B), sliding out of the cylinder (5) and

moving across the sloping face of swashplate (7), the pistons (6) rotate

the cylinder (5).

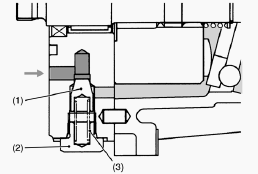

Charge Relief Valve

1 - Charge Relief Cone, 2 - Plug, 3 - Spring

While pumped and filtered oil flows into the main oil circuit through

the check and high pressure relief valves, and excessive oil passes to

the housing through the charge relief valve. Oil temperature - 50C

(122F). Valve operating pressure - 294 to 490 kPa (42.7 to 71.1 psi).

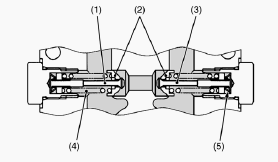

Check and High Pressure Relief Valve

1 - Relief Valve, 2 - Check Valve, 3 - Relief Valve, 4 - Relief Spring,

5 - Check Spring

The check and high pressure relief valves monitor the oil pressure in

each line of the main oil circuit. In neutral, both check valves are

open and charging oil enters into the main oil circuit through the

valves. At normal operation, the check valve in the high pressure side

is closed and it pushes and opens the another one. When excessively high

pressure is built up in one line, the high pressure relief valve located

in this line is open and the oil flows into another line. Oil

temperature - 50C (122F). Relief valve operating pressure - 13.7 MPa

(1991 psi).

Kubota BX2200, BX2230, BX2350, BX22 Tractor -

Power Take-Off System

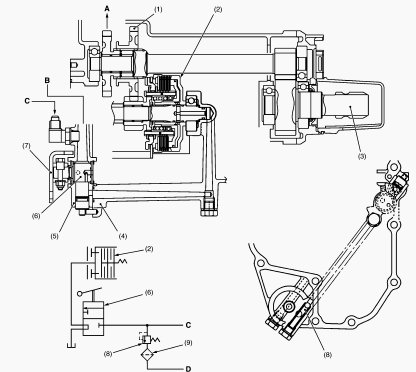

PTO Clutch and Valve

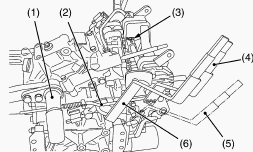

1-PTO Select Gear, 2-PTO Clutch Pack, 3-Rear PTO Shaft, 4-Transmission

Case, 5-Front Cover, 6-PTO Clutch Valve, 7-PTO Clutch Arm, 8-PTO Relief

Valve, 9-Oil Filter Cartridge, A-To Mid-PTO Shaft, B-Connected to PTO

Relief Valve, C-From Power Steering Controller, D-To Hydrostatic

Transmission

Kubota BX2200, BX2230, BX2350 tractors equipped with hydraulic

independent PTO clutch (wet multi-plates type). Therefore, the engine

power could engage or disengage to the PTO shafts without stopping the

tractor movement. The PTO clutch pack (2) has four clutch discs, four

drive plates, pressure plate, clutch piston and so on. The clutch piston

is actuated by hydraulic oil flow from the power steering controller.

The PTO clutch valve (6) controls the hydraulic oil flow from power

steering controller to the PTO clutch pack (2) by operating the PTO

clutch lever through linkage.

Power Take-Off Relief Valve

1 - PTO Clutch Valve, 2 - Plug, 3 - Spring, 4 - Steel Ball, A - From

Power Steering Controller, B - To Hydrostatic Transmission

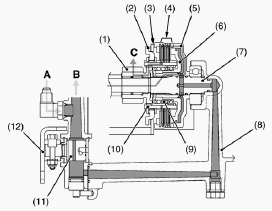

Power Take-Off Clutch Engaged

1 - 12T Gear Clutch, 2 - Brake Pressure Plate, 3 - Brake Disc, 4 -

Clutch Disc and Pressure Plate, 5 - Clutch Case, 6 - Clutch Piston, 7 -

Clutch Shaft, 8 - Transmission Case, 9 - Spring, 10 - Clutch Spline

Boss, 11 - PTO Clutch Valve, 12 - PTO Clutch Arm, A - From Power

Steering Controller, B - To Hydrostatic Transmission, C - To Mid and

Rear PTO Shaft

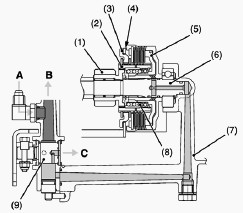

Power Take-Off Clutch Disengaged

1 - 12T Gear Clutch, 2 - Clutch Spline Boss, 3 - Brake Pressure Plate, 4

- Brake Disc, 5 - Clutch Piston, 6 - Clutch Shaft, 7 - Transmission

Case, 8 - Spring, 9 - PTO Clutch Valve, A - From Power Steering

Controller, B - To Hydrostatic Transmission, C - To Transmission Case

Kubota BX2200, BX2230, BX2350, BX22

Transmission Troubleshooting

Noise from Transmission - Transmission oil

insufficient. Gear worn or broken. Bearings worn.

Gear Slip Out of Mesh - Shift fork spring tension

insufficient. Shift fork or shifter worn. Shift fork bent.

Excessive or Unusual Noise at All Time - Improper

backlash between spiral bevel pinion and bevel gear. Improper backlash

between differential pinion and differential side gear. Bearing worn.

Insufficient or improper type of transmission fluid used.

Noise while Turning - Differential pinions or

differential side gears worn or damaged. Differential lock binding (does

not disengaged). Bearing worn.

Differential Lock Can Not Be Set - Differential lock

shift fork damaged. Differential lock shifter mounting pin damaged.

Differential lock pin damaged.

Differential Lock Pedal Does Not Return - Differential

lock pedal return spring weaken or damaged. Differential lock fork shaft

rusted.

Uneven Braking Force - Brake rod unevenly adjusted.

Brake disc worn. Actuator warped.

Brake Drags - Brake pedal free travel too small. Ball

holes of actuator for uneven wear. Brake pedal return spring weaken or

broken. Brake cam rusted.

Poor Braking Force - Brake pedal free travel excessive.

Brake disc worn. Actuator warped. Brake cam or lever damaged.

Transmission fluid improper.

PTO Clutch Slip - Operating pressure is low. PTO clutch

valve malfunctioning. Clutch disc or drive plate excessively worn.

Deformation of clutch piston.

PTO Shaft Does Not Rotate - PTO clutch malfunctioning.

PTO Clutch Operating Pressure is Low - Transmission oil

improper or insufficient. Relief valve malfunctioning.

PTO Clutch Drags - Brake plate excessive worn. Clutch

spring weaken or broken. Deformation of pressure plate or steel plate.

Kubota BX2200, BX2230, BX2350, BX22 -

Transmission Disassembling and Assembling

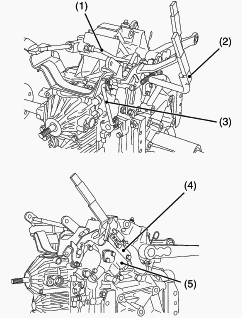

Levers and Mower Lift Arm

1-Mower Lift Arm, 2-Feedback Rod, 3-Rue Ring, 4-Hydraulic Control Lever,

5-Front Wheel Drive Lever, 6-Range Gear Shift Lever

Tap out the spring pin from the range gear shift lever (6) and front

wheel drive lever (5), then remove the both levers. Remove the mower

lift arm (1) with feedback rod (2). Remove the rue ring (3) and

hydraulic control lever mounting bolt and nut, then remove the hydraulic

control lever (4).

Neutral Plate and Neutral Switch Stay

Remove the trunnion arm mounting bolt and nut. Remove the neutral plate

mounting screws, then remove the neutral plate. Remove the neutral

switch stay.

Hydrostatic Transmission Assembly

Remove the hydrostatic transmission assembly from transmission case.

Apply oil to the O-rings and take care not to damage them. Apply liquid

lock to the thread of hydrostatic transmission mounting screws.

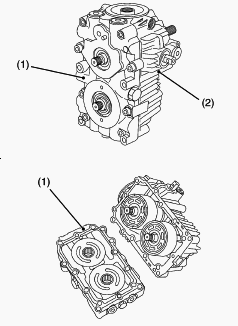

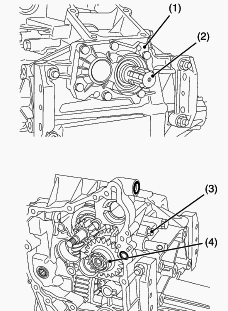

Center Section and Charge Relief Valve

1-Center Section, 2-HST Housing

Remove the center section mounting hex. socket head screws. Tap the

center section (1) with soft hammer and separate the center section (1)

from the HST housing (2). Cover the splines of each shaft with thin tape

to protect the sealing lip of the oil seals. Place a new gasket on the

HST housing. Take care not to damage the surface of cylinder blocks,

pistons and center section. Charge Relief Valve - Remove the plug and

draw out the spring and charge relief cone. Take care not to damage the

O-ring on the plug.

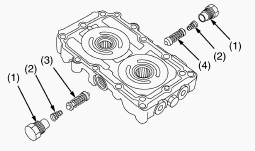

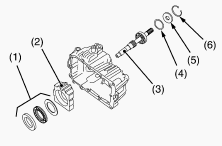

Check and High Pressure Relief Valve

1-Plug, 2-Spring, 3-Check and High Pressure Relief Valve Assembly

(Forward), 4-Check and High Pressure Relief Valve Assembly (Reverse)

Remove the plug (1) and draw out the spring (2) and check and high

pressure relief valve assembly (3), (4). Take care not to damage the

O-ring on the plug.

Cylinder Block Assembly and Thrust Ball

Bearing

1-Cylinder Block Assembly (Pump Side), 2-Cylinder Block Assembly (Motor

Side), 3-Motor Shaft, 4-Thrust Ball Bearing

Remove the cylinder block assembly (pump side) (1). Remove the cylinder

block assembly (motor side) (2) with the motor shaft (3). Remove the

thrust ball bearing (4). Apply clean transmission oil to thrust ball

bearing, cylinder block and piston.

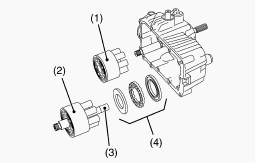

Swashplate and Pump Shaft

1-Thrust Roller Bearing, 2-Swashplate, 3-Pump Shaft, 4-Spacer, 5-Oil

Seal, 6-Internal Snap Ring

Remove the swashplate (2) and thrust roller bearing (1) from the HST

housing. Remove the internal snap ring (6) and tap out the pump shaft

(3), spacer (4) and oil seal (5). Apply clean transmission oil to the

thrust roller bearing.

Cradle Bearing, Slot Guide and Trunnion Arm

Remove the slot guide and trunnion arm. Remove the cradle bearing from

the HST housing. Apply clean transmission oil to the cradle bearing and

trunnion arm. Fasten down the cradle bearing to the HST housing.

Kubota BX2200, BX2230, BX2350, BX22 -

Transmission Case Disassembly and Assembly

Levers and Mower Lift Arm

1-Mower Lift Arm, 2-Feedback Rod, 3-Rue Ring, 4-Hydraulic Control Lever,

5-Front Wheel Drive Lever, 6-Range Gear Shift Lever

Tap out the spring pin from the range gear shift lever (6) and front

wheel drive lever (5), then remove the both levers. Remove the mower

lift arm (1) with feedback rod (2). Remove the rue ring (3) and

hydraulic control lever mounting bolt and nut, then remove the hydraulic

control lever (4).

Neutral Plate and Neutral Switch Stay

Remove the trunnion arm mounting bolt and nut. Remove the neutral plate

mounting screws, then remove the neutral plate. Remove the neutral

switch stay.

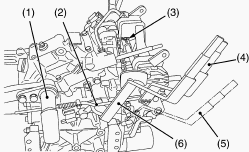

PTO Select Lever and Control Valve

1-Delivery Pipe, 2-PTO Select Lever, 3-PTO Clutch Rod, 4-PTO Safety

Switch Stay, 5-Control Valve

Remove the delivery pipe (1) and PTO clutch rod (3). Tap out the spring

pin and remove the PTO select lever (2). Remove the control valve (5)

with PTO safety switch stay (4). Apply oil to the O-rings and take care

not to damage them.

Hydraulic Pump and Suction Pipe

Remove the hydraulic pump and suction pipe from the transmission case.

Do not twist the suction hose. Take care not to damage the O-rings.

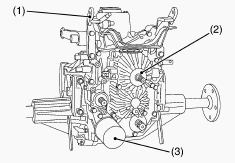

Seat Rail Front Stay and Hydrostatic

Transmission Assembly

1-Seat Rail Front Stay, 2-Hydrostatic Transmission Assembly, 3-Oil

Filter Cartridge

Remove the seat rail front stay (1). Remove the hydrostatic transmission

assembly (2) and oil filter cartridge (3). Apply oil to the O-rings and

take care not to damage them. Apply liquid lock (Three Bond 1324 or

equivalent) to the thread of hydrostatic transmission mounting screws.

Kubota BX2200, BX2230, BX2350, BX22 -

Hydraulic Cylinder

Remove the hydraulic cylinder mounting screws and dismount the hydraulic

cylinder. Apply liquid gasket to joint face of the transmission case to

hydraulic cylinder.

Front Cover

Remove the front cover mounting screws and separate the front cover.

Apply liquid gasket to joint face of the transmission case to front

cover. The spring pin on the front wheel drive idle shaft and gear pump

idle shaft should face upper side. Apply grease to the collar on the

front wheel drive shaft. Take care not to damage the O-ring.

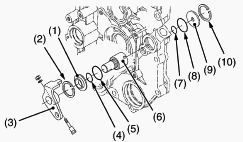

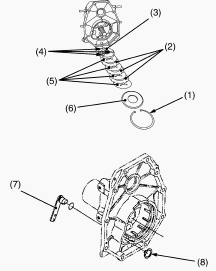

PTO Clutch Valve

1-PTO Clutch Sleeve, 2-Internal Snap Ring, 3-PTO Clutch Arm, 4-O-ring,

5-O-ring, 6-PTO Clutch Valve, 7-O-ring, 8-O-ring, 9-PTO Clutch Collar,

10-Internal Snap Ring

Remove the PTO clutch arm (3). Remove the internal snap ring (10), then

draw out the PTO clutch collar (9) and PTO clutch valve (6). Remove the

internal snap ring (2) and draw out the PTO clutch sleeve (1). Take care

not to damage the O-rings.

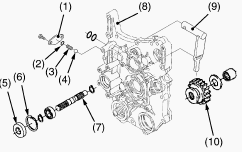

Front Wheel Drive Shaft and Shift Fork

1-Plate, 2-O-ring, 3-Spring, 4-Steel Ball, 5-Oil Seal, 6-Internal Snap

Ring, 7-Front Wheel Drive Shaft, 8-Front Cover, 9-Front Wheel Drive

Shift Fork, 10-19T Shifter Gear

Remove the plate (1), then draw out the spring (3) and steel ball (4).

Remove the oil seal (5) and internal snap ring (6). Tap out the front

wheel drive shaft (7) to the front. Remove the 19T shifter gear (10) and

front wheel drive shift fork (9). Take care not to damage the O-ring.

Replace the oil seal (5) with new one.

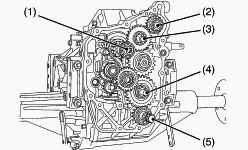

13T Gear, 19T Gear Shaft, Hydraulic Pump Idle

Shaft, Mid-PTO Shaft and Mid-PTO Idle Shaft

1 - 13T Gear Assembly, 2 - 19T Gear Shaft Assembly, 3 - Hydraulic Pump

Idle Shaft Assembly, 4 - Mid-PTO Idle Shaft Assembly, 5 - Mid-PTO Shaft

Assembly

Remove the 13T gear assembly (1), 19T gear shaft assembly (2) and

hydraulic pump idle shaft assembly (3). Remove the mid-PTO shaft

assembly (5) and mid-PTO idle shaft assembly (4).

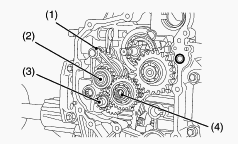

Spiral Bevel Gear Shaft, 17T-25T Gear Shaft

and Front Wheel Drive Idle Shaft

1 - Range Gear Shift Fork, 2 - Spiral Bevel Gear Shaft Assembly, 3 -

Front Wheel Drive Idle Shaft Assembly, 4 - 17T-25T Gear Shaft Assembly

Remove the front wheel drive idle shaft assembly (3) and 17T-25T gear

shaft assembly (4). Remove the spiral bevel gear shaft assembly (2)

together with range gear shift fork (1). Install all of the above

mentioned parts, simultaneously.

Rear Cover, Rear PTO Shaft and Rear PTO Drive

Shaft

1-Rear Cover, 2-Rear PTO Shaft Assembly, 3-PTO Select Bolt, 4-Rear PTO

Drive Shaft Assembly

Remove the rear cover (1) and rear PTO shaft assembly (2). Remove the

PTO select bolt (3) and draw out the spring and steel ball. Remove the

rear PTO drive shaft assembly (4). Apply liquid gasket to joint face of

the transmission case to rear cover. Apply grease to the lip of oil

seal.

Final Gear Shaft and Differential Gear

Assembly

Draw out the final gear shaft assembly, differential gear assembly and

differential lock shift fork. Take care not to damage the O-ring.

Kubota BX2200, BX2230, BX2350, BX22 -

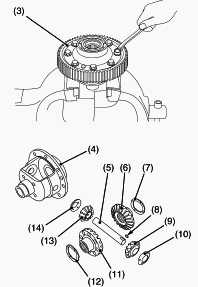

Disassembling Differential Gear Assembly

3 - 66T Final Gear, 4 - Differential Case, 5 - Differential Pinion

Shaft, 6 - Differential Side Gear, 7 - Differential Side Gear Washer, 8

- Key, 9 - Differential Pinion, 10 - Differential Pinion Washer, 11 -

Differential Side Gear, 12 - Differential Side Gear Washer, 13 -

Differential Pinion, 14 - Differential Pinion Washer

Remove the bearing (1), differential lock shifter (2) and 66T final gear

(3). Put parting marks on the differential pinions (9), (13) and the

differential side gears (6), (11). Tap out the differential pinion shaft

(5). Remove the differential pinions (9), (13), differential pinion

washers (10), (14), differential side gears (6), (11) and differential

side gear washers (7), (12). Install the differential pinion and

differential side gear, aligning the parting marks. Lock the

differential pinion shaft (5) by setting the key (8).

Brake Disc and Friction Plate

1-Internal Snap Ring, 2-Friction Plate, 3-Actuator, 4-Steel Ball,

5-Brake Disc, 6-Bearing Holder, 7-Cam Lever, 8-External Snap Ring

Remove the internal snap ring (1). Remove the bearing holder (6), brake

discs (5), friction plates (2), actuator (3) and steel balls (4). Remove

the external snap ring (8), then remove the cam lever. Apply grease to

the steel balls. Install the brake discs with their holes deviation at

less than 1/3 of the total hole area. When installing the bearing

holder, do not forget to install the straight pin. Install the internal

snap ring (1) as shown in the figure. (Open end of the snap ring should

place bottom side). Take care not to damage the O-ring.

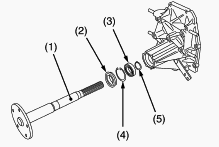

Rear Axle

1-Rear Axle, 2-Oil Seal, 3-Bearing, 4-Internal Snap Ring, 5-External

Snap Ring

Remove the oil seal (2), then remove the internal snap ring (4). Tap out

the rear axle (1) from transmission case or rear axle cover. Do not

apply oil to the outer circumference of the oil seal.

Kubota BX2200, BX2230, BX2350, BX22 Tractor -

Transmission Servicing

Clearance between Differential Case and

Differential Side Gear

Measure the differential side gear boss O.D. with an outside micrometer.

Measure the differential case I.D. with a cylinder gauge and calculate

the clearance. If the clearance exceeds the allowable limit, replace

faulty parts. Clearance between differential case and differential side

gear - 0.050 to 0.151 mm / 0.0020 to 0.0059 in. Allowable limit - 0.30

mm / 0.0118 in. Differential case I.D. - 38.000 to 38.062 mm / 1.4961 to

1.4985 in. Differential side gear O.D. - 37.911 to 37.950 mm / 1.4926 to

1.4941 in.

Clearance between Differential Pinion Shaft

and Differential Pinion

Measure the differential pinion shaft O.D. with an outside micrometer.

Measure the differential pinion I.D. with a cylinder gauge, and

calculate the clearance. If the clearance exceeds the allowable limit,

replace faulty parts. Clearance between differential pinion shaft and

differential pinion - 0.080 to 0.122 mm / 0.0031 to 0.0048 in. Allowable

limit - 0.30 mm / 0.0118 in. Differential pinion I.D. - 20.060 to 20.081

mm / 0.7898 to 0.7906 in. Differential pinion shaft O.D. - 19.959 to

19.980 mm / 0.7858 to 0.7866 in.

Backlash between Differential Pinion and

Differential Side Gear

Secure the differential case with a vise. Set the dial indicator (lever

type) with its finger on the tooth of the differential side gear. Press

differential pinion and side gear against the differential case. Hold

the differential pinion and move the differential side gear to measure

the backlash. If the backlash exceeds the allowable limit, adjust with

differential side gear shims. Backlash between differential pinion and

differential side gear - 0.15 to 0.30 mm / 0.0059 to 0.0118 in.

Allowable limit - 0.40 mm / 0.0157 in.

Side Clearance of Spiral Bevel Pinion Shaft

Temporary assemble the spiral bevel pinion shaft and front cover to the

transmission case. Set the dial indicator (lever type) with its finger

on the end of spiral bevel pinion shaft. Move the spiral bevel pinion

shaft back and forth to each end and measure the side clearance. If the

side clearance exceeds the factory specifications, adjust with the shim

at front end of spiral bevel pinon shaft. Side clearance of spiral bevel

pinion shaft - 0.1 to 0.3 mm / 0.0039 to 0.0118 in.

Backlash between Spiral Bevel Pinion Shaft and

Spiral Bevel Gear

Temporary assemble the spiral bevel pinion shaft, and properly adjust

the side clearance. Place fuses between spiral bevel pinion shaft and

spiral bevel gear. Assemble the axle cover assembly, and turn the rear

axle. Remove the axle cover assembly, and take out the fuses. Measure

the thickness of fuses with an outside micrometer. If the measurement is

not within the factory specifications, adjust with shims. Backlash

between spiral bevel pinion shaft and spiral bevel gear - 0.1 to 0.3 mm

/ 0.0039 to 0.0118 in.

Flatness of Actuator and Bearing Holder

Place a straightedge of 150 mm (5.91 in.) or more in length on the

contacting surface of the actuator and the bearing holder. Inspect the

friction surface of the actuator and the bearing holder with the

straightedge, and determine if a 0.30 mm (0.0118 in.) feeler gauge will

fit on the part of wear. If it will fit, resurface. Flatness of actuator

and bearing holder - Allowable limit 0.30 mm / 0.0118 in.

Height of Cam Plate and Ball

Measure the height of the cam plate with the ball installed. If the

measurement is less than the allowable limit, replace the cam plate and

balls. Inspect the ball holes of cam plate for uneven wear. If the

uneven wear is found, replace it. Height of cam plate and ball - 22.89

to 22.99 mm / 0.9012 to 0.9051 in. Allowable limit - 22.40 mm / 0.8819

in.

Brake Disc and Friction Plate Wear

Measure the brake disc thickness and the friction plate thickness with

an outside micrometer. If the thickness is less than the allowable

limit, replace it. Brake disc thickness - 3.3 to 3.5 mm / 0.130 to 0.138

in. Allowable limit - 3.0 mm / 0.118 in. Friction plate thickness - 1.92

to 2.08 mm / 0.0756 to 0.0819 in. Allowable limit - 1.52 mm / 0.0598 in.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA ENGINES DATA AND SERVICE SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA FRONT END LOADERS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| KUBOTA TRACTORS TROUBLESHOOTING | ||||

| L235 | L2501 | L2550 | L275 | L3110 |

| L3301 | L35 | L3710 | L3901 | L4310 |

| L5030 | M4700 | M5700 | M6040 | M6800 |

| M8200 | M8540 | M9000 | MX5100 | MX5200 |

SPECIFICATIONS

SPECIFICATIONS LOADERS

LOADERS ENGINES

ENGINES MAINTENANCE

MAINTENANCE PROBLEMS

PROBLEMS B1241

B1241 B1600

B1600 B1700

B1700 B1750

B1750 B21 Backhoe

B21 Backhoe B2150

B2150 B2301

B2301 B2320

B2320 B2530

B2530 B26 Backhoe

B26 Backhoe B2601

B2601 B2650HSD

B2650HSD B3030

B3030 B3350

B3350 B6000

B6000 B6100

B6100 B6200

B6200 B7000

B7000 B7001

B7001 B7100HST

B7100HST B7200

B7200 B7500

B7500 B7510

B7510 B7800

B7800 B8200HST

B8200HST BX1880

BX1880 BX2200

BX2200 BX2230

BX2230 BX2350

BX2350 BX2370

BX2370 BX23S

BX23S BX25 TLB

BX25 TLB BX2660

BX2660 BX2680

BX2680 F3680

F3680 L175

L175 L185

L185 L210

L210 L225

L225 L235

L235 L245

L245 L260

L260 L275

L275 L285

L285 L305

L305 GR2120

GR2120 L1501

L1501 L2350

L2350 L2550

L2550 L2800

L2800 L3010

L3010 L3200HST

L3200HST L3301

L3301 L3560

L3560 L3800

L3800 L4701

L4701 L5740

L5740 M5-091

M5-091 M5-111

M5-111 M6060

M6060 M7040

M7040 M9540

M9540 M9960

M9960 MX5100

MX5100 D662

D662 D722

D722 D750

D750 D782

D782 D850

D850 D902

D902 D905

D905 D950

D950 D1005

D1005 D1100

D1100 D1105

D1105 D1503

D1503 D1703

D1703 D1803

D1803 V1200

V1200 V1205

V1205 V1305

V1305 V1505

V1505 V2203

V2203 V2403

V2403 Z482

Z482 Z602

Z602 Z750

Z750 Z1100

Z1100 Z1300

Z1300 B1630

B1630 BF400

BF400 BF400G

BF400G LA181

LA181 LA203

LA203 LA211

LA211 LA243

LA243 LA271

LA271 LA272

LA272 LA301

LA301 LA302

LA302 LA304

LA304 LA340

LA340 LA344

LA344 LA351

LA351 LA352

LA352 LA364

LA364 LA401

LA401 LA402

LA402 LA434

LA434 LA463

LA463 LA481

LA481 LA482

LA482 LA504

LA504 LA513

LA513 LA514

LA514 LA524

LA524 LA525

LA525 LA534

LA534 LA555

LA555 LA680

LA680 LA681

LA681 LA682

LA682 LA703

LA703 LA714

LA714 LA723

LA723 LA724

LA724 LA764

LA764 LA765

LA765 LA805

LA805 LA844

LA844 LA852

LA852 LA853

LA853 LA854

LA854 LA1002

LA1002 LA1055

LA1055 LA1065

LA1065 LA1153

LA1153 LA1154

LA1154 LA1251

LA1251 LA1301S

LA1301S LA1353

LA1353 LA1403

LA1403 LA1601S

LA1601S LA1854

LA1854 LA1944

LA1944 LA1953

LA1953 LA2253

LA2253 LM2605

LM2605