________________________________________________________________________________

Case IH Tractor Independent PTO

The power take off used on Case IH Tractor 385/485/585/685 is an

independent type. The pto is available as a single speed (540 rpm) unit

or as a dual speed (540 and 1000 rpm) unit. Oil for the pto unit on

tractor models is furnished from the hydraulic pump through the multiple

control valve.

From the MCV, the oil is supplied through a cored passage in the rear

frame to the 1000 rpm output shaft or lower pto drive shaft to actuate

the pto clutch. Operation of the pto clutch unit is controlled by a

spool type valve located in the MCV housing.

Pto control linkage adjustments

Although some checks and adjustments can be accomplished without

removing left rear wheel, most mechanics prefer to remove the wheel to

gain working room.

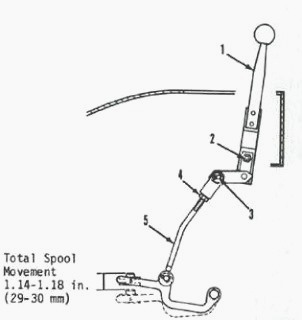

Fig.13. PTO control linkage used on Case IH Tractor

385/485/585/685 not equipped with cab

To adjust the pto linkage on tractor models without cab, refer to Figure

and move control lever (1) for-ward and rearward to check total control

spool movement. Total spool movement should be 1.14-1.18 inches (29-30

mm).

If not, remove pin (3), loosen lock-nut (4) and adjust clevis on link

(5) to obtain correct total spool movement. Install pin and tighten

lock-nut.

Make certain control lever has a small amount of clearance between lever

and end of slot in console. If necessary, loosen clamp bolt (2) and

while holding linkage in position move lever to adjust. Then, tighten

clamp bolt.

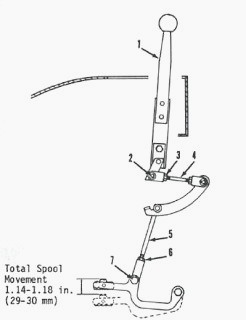

Fig.14. PTO control linkage used on models equipped with cab

To adjust the pto linkage on models equipped with cab, refer to Figure

and move control lever (1) forward and rearward to check total control

spool movement. Total spool movement should be 1.14-1.18 inches (29-30

mm).

If not, remove pin (7), loosen lock-nut (6) and adjust clevis on link

(5) to obtain correct total spool movement. Install pin and tighten

lock-nut.

Check to see that control lever has a small amount of clearance at each

end of slot in console. If necessary, remove pin (2), loosen locknut (3)

and adjust clevis on link (4) until clearance is obtained. Install pin

and tighten locknut.

Operating pressure test

To check operating pressure, operate tractor until hydraulic fluid is

warmed to at least 100° F (38° C). Connect a 0-300 psi (0-2000 kPa)

pressure gage (1) to the tee fitting (2).

Start tractor and operate at low idle speed. Move pto control lever forward to engaged position. Pressure reading on gage should be 260-270 psi (1790-1860 kPa).

If reading is correct, there is no problem in hydraulic system of the pto. If reading is not correct, remove test gage and remove pressure line from MCV to tee fitting.

Cap tee fitting and connect test gage to the pto outlet union on the

MCV. Operate engine at low idle speed and move pto control lever forward

to engaged position.

If pressure was low in first test but is now

correct, check for following conditions and correct as required:

- Damage to lock ring seals on bottom pto shaft.

- Damage to pto shaft bushing in transmission housing.

- Damage to seals or piston in pto clutch of Case IH Tractor.

- If pressure is low in second test, there is a fault in the hydraulic

supply, pto spool, regulator valve or MCV gasket.

With the 0-300 psi (0-2000 kPa) pressure gage still connected to the pto

outlet union on the MCV, move pto control lever rearward into disengaged

position. Reading on gage must be zero. A pressure reading on the gage

would indicate that spool is not fully up or there is wear on the spool

lands.

Move the control lever forward until the pto spool moves downward

0.39-0.43 inch (10-11 mm) (initial engagement position). Pressure

reading should be 41-46 psi (283-317 kPa).

Record the gage reading, then move control lever fully rearward to

disengaged position. Move control lever fully forward to engaged

position. Gage reading should be 260-270 psi (1790-1860 kPa).

If initial engagement pressure is low but the full engagement pressure

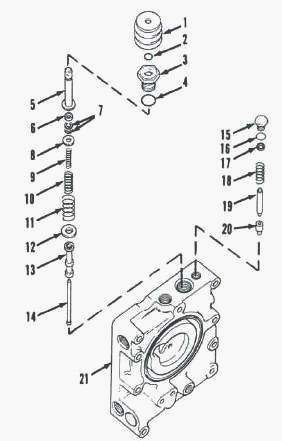

is correct, remove the pto spool assembly. See Figure. Inspect the spool

lands and if in good condition, add a shim (7). Each shim will increase

the initial engagement pressure 3 psi (21 kPa).

Fig.15. PTO control spool and regulator valve

If the initial engagement pressure is correct but the full engagement

pressure is low, remove regulator valve (15 through 20), Inspect the

regulator valve poppet (20) and seat and if in good condition, add a

shim (17).

Each shim will increase the full engagement pressure 20-30 psi (138-207

kPa). Repeat pressure tests after adding shims or renewing any parts.

Case IH Tractor 385/485/585/685 PTO

clutch, shafts and gears

Overhaul

To remove the pto clutch, first drain range transmission and remove

clutch cover or transfer case, as equipped. Rotate upper pto output

shaft until roll.

Drive roll pin from clutch and shaft. Unbolt and remove lower pto shaft

cover or seal housing, as equipped, and remove gasket from rear of

tractor.

Have helper support pto clutch and idler gears, if so equipped. Withdraw

1000 rpm output shaft (dual speed) or lower drive shaft (single speed).

Remove idler gears, if so equipped, and pto clutch as shaft is

withdrawn.

Fig.16. Pto clutch, gears and shafts. Inset shows the 1000 rpm

shaft used In place of lower drive shaft

1-Shaft cover, 2-Bearing & seal retainer, 3-Gasket, 4-Oil seal, 5-Snap

ring, 6-Washer, 7-Ball bearing, 8-540 rpm shaft, 9-Gear, 10-Snap ring,

11-Snap ring, 12-Needle bearing, 13-Snap ring, 14-"O" ring, 15-Idler

shaft, 16-Needle bearing, 17-Idler gear, 18-Cover, 19-Gasket, 20-Snap

ring, 21-Ball bearing, 22-Lower drive shaft (540 rpm), 23-Gear, 24-Snap

ring, 25-Seal rings, 26-Bushing, 27-Needle bearing, 28-Sleeve, 29-Roller

bearing, 30-Idler gear, 31-Clutch cup, 32-Piston, 30-O ring (inner),

34-"O" ring (outer), 35-Brake ring, 36-Piston back plate, 37-Friction

disc, 38-Drive plates, 39-Return springs, 40-Clutch back plate, 41-Snap

ring, 42-Thrust washer, 43-Clutch hub, 44-Snap ring, 45-Needle bearing,

46-Shaft safety cover, 47-Bearing seal retainer, 48-Gasket, 49-Oil

seal, 50-Snap ring, 51-Ball bearing, 52-1000 rpm shaft

To disassemble the pto clutch, first use a pair of "C" clamps or a

suitable puller and compress the return springs (39), then remove snap

ring (41). Remove clamps or

puller and remove clutch back plate (40) and return springs (39).

Remove friction discs (37), drive plates (38), piston back plate (36)

and brake ring (35). Remove snap ring (44), thrust washer (42) and

clutch hub (43). Bump front of

clutch cup (31) on bench top and remove piston (32) with "O" rings (33

and 34).

Case IH Tractor Standard duty pto clutch has five friction discs and

eight drive plates (two drive plates between each friction disc). Heavy

duty pto clutch has six friction

discs and five drive plates (one between each friction disc).

Clean and inspect all parts and renew any showing excessive wear or

other damage. Pay particular attention to the clutch friction discs and

drive plates which should be

free of scoring or warpage. Use all new "0" rings, seals and gaskets

during reassembly.

Bushing (26) for the 1000 rpm output shaft (52) or lower drive shaft

(22) on 540 rpm unit is in the front of differential compartment. This

bushing should be renewed if new

shaft (52) or (22) is required or if seal rings (25) have grooved the

bushing.

When installing bushing (26) bottom it in bore. Position needle bearing

(27) to within 1/32-3/32 inch (0.79-2.38 mm) of front face of bushing

(26).

Unlock and remove seal rings (25). Remove snap rings (24) and (20) or

(50), then press bearing (21) or (51) off rear of shaft (22) or (52) and

press gear (23) off front of

shaft. Check to see that oil holes are clear and that roll pin is

tightly in position in shaft. Use new seal rings and snap rings during

assembly.

Inspect sleeve (28), roller bearing (29) and idler gear (17), if so

equipped, and renew as necessary. Sleeve has a slot which must be

aligned with pin in shaft (22) or (52)

during assembly. Reassemble and reinstall PTO by reversing disassembly

and removal procedures.

To remove the 540 rpm output shaft (8), gear (9), idler shaft (15) and

idler gear (17), first remove hydraulic lift assembly. Remove snap ring

(10) and unbolt bearing and

seal retainer (2).

Withdraw output shaft assembly and remove gear (9) through top opening.

Install a cap screw in rear of idler shaft (15), pull idler shaft from

rear of frame and remove

idler gear (17) from above. Use new' 'O'' ring (14), oil seal and gasket

and reinstall by reversing the removal procedure.

________________________________________________________________________________

________________________________________________________________________________________

| CASE IH TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH FRONT END LOADERS SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CASE IH SPECS

CASE IH SPECS J.I. CASE SPECS

J.I. CASE SPECS PROBLEMS

PROBLEMS LOADERS

LOADERS FARMALL 110A

FARMALL 110A FARMALL 120A

FARMALL 120A FARMALL 30C

FARMALL 30C FARMALL 75C

FARMALL 75C MAGNUM 280

MAGNUM 280 580E Backhoe

580E Backhoe 580L Backhoe

580L Backhoe 580N Backhoe

580N Backhoe 580 Super L

580 Super L 580SM Backhoe

580SM Backhoe 580SLE Backhoe

580SLE Backhoe 580SN Backhoe

580SN Backhoe 580M Backhoe

580M Backhoe 580 Super E

580 Super E 580ST Backhoe

580ST Backhoe MAGNUM 310

MAGNUM 310 MAGNUM 340

MAGNUM 340 MAXXUM 110CVX

MAXXUM 110CVX MAXXUM 120CVX

MAXXUM 120CVX MAXXUM 125

MAXXUM 125 1394

1394 1455XL

1455XL 1494

1494 1594

1594 3230

3230 4210

4210 585XL

585XL 633

633 695XL

695XL 733

733 MX110

MX110 MX135

MX135 MX150

MX150 MXU110

MXU110 MXU135

MXU135 PUMA 175CVX

PUMA 175CVX PUMA 185CVX

PUMA 185CVX PUMA 200CVX

PUMA 200CVX PUMA 240CVX

PUMA 240CVX OPTUM 300

OPTUM 300 FARMALL 50B

FARMALL 50B FARMALL 95U

FARMALL 95U FARMALL 125A

FARMALL 125A PUMA 150

PUMA 150 PUMA 165

PUMA 165 MAGNUM 210

MAGNUM 210 MX 170

MX 170 MAXXUM 150

MAXXUM 150 OPTUM 270

OPTUM 270 MAGNUM 315

MAGNUM 315 FARMALL 70

FARMALL 70 FARMALL 75N

FARMALL 75N FARMALL 95C

FARMALL 95C FARMALL 105N

FARMALL 105N FARMALL 30B

FARMALL 30B L103 Loader

L103 Loader L104 Loader

L104 Loader L105 Loader

L105 Loader L106 Loader

L106 Loader L107 Loader

L107 Loader L108 Loader

L108 Loader L130 Loader

L130 Loader L160 Loader

L160 Loader L300 Loader

L300 Loader L340 Loader

L340 Loader L350 Loader

L350 Loader L360 Loader

L360 Loader L530 Loader

L530 Loader L540 Loader

L540 Loader L545 Loader

L545 Loader L550 Loader

L550 Loader L555 Loader

L555 Loader L560 Loader

L560 Loader L565 Loader

L565 Loader L570 Loader

L570 Loader L575 Loader

L575 Loader L720 Loader

L720 Loader L730 Loader

L730 Loader L735 Loader

L735 Loader L740 Loader

L740 Loader LRZ 95

LRZ 95 LRZ 100

LRZ 100 LRZ 120

LRZ 120 LRZ 130

LRZ 130 LRZ 150

LRZ 150 L745 Loader

L745 Loader L750 Loader

L750 Loader L755 Loader

L755 Loader L760 Loader

L760 Loader L765 Loader

L765 Loader L770 Loader

L770 Loader L775 Loader

L775 Loader L780 Loader

L780 Loader L785 Loader

L785 Loader L795 Loader

L795 Loader 90 Loader

90 Loader 890 Loader

890 Loader 2200 Loader

2200 Loader 2250 Loader

2250 Loader LX156 Loader

LX156 Loader