________________________________________________________________________________

Case 485, 685 Tractor steering hand pump

Overhaul

To remove the steering hand pump, proceed as follows: On Case IH 485,

685 Tractor without cab, remove battery access panel and disconnect

battery cables. Unbolt and remove upright muffler. Remove radiator cap,

tractor hood and side panels. Remove battery and insulation pad from

battery tray.

Using a suitable puller, remove steering wheel. Remove nut from ignition

switch and push switch to inside. Unbolt and remove instrument panel

side panels. Unbolt instrument panel and raise about 2 inches (50 mm) on

right side and support in this position.

On Case IH 685, 485 Tractor with XL cab, remove battery cover,

disconnect battery cables and remove battery. Using a suitable puller,

remove steering wheel.

Push in and turn lockpins, then lift off the instrument panel front

housing. Loosen locknut and remove engine stop control knob. Remove

locknut and grommet from instrument panel.

Disconnect tachometer cable. Lift instrument panel upward to clear

steering shaft, then move the panel to the right and support assembly in

this position.

On all models, identify and disconnect the four steering hoses from hand

pump. Plug or cap all openings. Remove the two hand pump retaining cap

screws and lower the unit. Remove the two spacers, then remove hand pump

assembly.

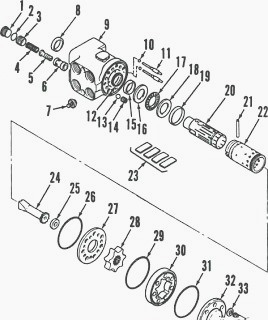

To disassemble the steering hand pump, clean exterior of assembly, then

unbolt and remove steering shaft and column. Scribe match marks across

end cover (32—Fig.11), stator (30), distributor plate (27) and housing

(9). Clamp valve housing in a soft jawed vise in inverted position and

remove end cover cap screws.

Remove end cover (32), stator (30), spacer (25), rotor (28), distributor

plate (27) and drive shaft (24). Using a screwdriver and a magnet,

unscrew and remove threaded bushing (14) and ball (13).

Remove unit from vise and shake suction pins (11) and balls (10) from

housing. DO NOT use a magnet to remove pins and balls. Push valve spool

assembly from housing.

Remove thrust washers (16 and 18), needle bearing (17) and retaining

ring (19) from end of spool. Remove cross pin (21) from spool, then

slide spool (20) from sleeve (22). Remove inner and outer plate springs

(23). Remove seal ring (15), "O" ring (12) and dust seal (8) from

housing.

Using an Allen wrench, remove plug (1) with "o" ring (2). Note the

position of the adjusting plug (3), then unscrew while counting the

number of turns needed to remove the adjusting plug.

Record the number of turns to aid in reassembly. Remove spring (4) and

relief valve (5). DO NOT remove seat (6) or check valve (7) as they are

not available as replaceable parts.

Fig.11. Exploded view of the Danfoss steering hand pump

Clean and inspect all parts for excessive wear or other damage. If

housing (9), seat (6), check valve (7), spool (20), sleeve (22), rotor

(28) or stator (30) are not suitable for further service, renew complete

hand pump assembly as these parts are not serviced separately.

All' 'O'' rings, seals and plate springs are available in a seal kit.

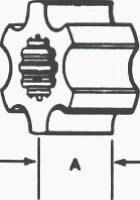

Check rotor (28) and stator (30) for wear as follows: Refer to Fig.2 and

measure thickness of rotor at (A) and stator at (B).

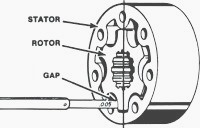

If (A) is 0.002 inch (0.051 mm) less than (B), renew hand pump. Refer to

Fig. 12 and place rotor in stator as shown. Using a feeler gage, measure

gap as shown. If gap is 0.005 inch (0.127 mm) or more, renew hand pump

assembly.

Fig.12. When checking rotor and stator, measure distance "A" on rotor

Fig.13. Distance "B" on stator

Reassemble by reversing the disassembly procedure keeping the following

points in mind. Lubricate all internal parts with Hy-Tran Plus fluid and

coat all "O" rings with

petroleum jelly during reassembly.

When installing plate springs (23—Fig.11), first install the two flat

springs. Then, install the two curved springs (arches back to back) in

between the two flat springs.

When installing rotor (28) on shaft (24), make certain that cross pin

slot in shaft aligns with center of a valley in rotor. Align match marks

and tighten end cover cap

screws (35) to a torque of 22-26 ft.-lbs. (30-35 N-m).

Fig.14. Use a feeler gage to measure gap between rotor and

stator

Reinstall steering column and upper shaft on pump and tighten cap screws

to a torque of 33-37 ft.-lbs. (45-50 N-m). Install hand pump and two

spacers in place, then

install the two retaining cap screws and torque to 33-37 ft.-lbs. (45-50

N-m).

With pump installation completed, install all removed parts (battery,

hood, panels and instrument panel) except access panel to adjust relief

valve (5) pressure.

Refer to paragraph 23 and adjust relief valve pressure as follows:

Remove plug (1—Fig.11) and with engine operating at 1000 rpm, check

relief pressure on gage.

Pressure should be 2150 psi (14825 kPa). Turn adjusting plug (3) inward

to increase pressure or outward to decrease pressure. Install and

tighten plug (1) and

complete balance of installation.

Case 485, 685 Tractor steering hand pump test

To test the steering hand pump, disconnect steering hose from left end

of steering cylinder. Cap cylinder fitting. Connect a hose and 4000 psi

(28000 kPa) test gage to

the steering hose. Remove center cap from steering wheel.

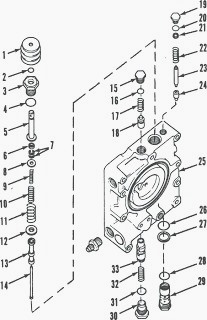

Fig.15. Exploded view of the multiple control valve assembly

With engine stopped, use a torque wrench and apply 52 ft.-lbs. (70 W-m)

of torque to the steering wheel nut in a counterclockwise direction.

Check the reading on the

test gage. Pressure reading should be not less than 55 psi (380 kPa).

If pressure reading is not correct, check for the following conditions:

- Worn Case IH 485, 685 Tractor steering hand pump or damaged seals.

- Worn or stuck cheek ball in hand pump.

- Stuck check valve in pressure inlet port of hand pump.

Then, with engine operating at 1000 rpm, turn steering wheel

counterclockwise and check pressure gage reading. Pressure should read

2150 psi (14825 kPa).

If pressure reading is not correct, check for following conditions:

- Relief valve stuck in hand pump. Incorrect relief valve setting.

- Correct the problem and retest.

- Remove pressure gage and connect steering hose to cylinder.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH FRONT END LOADERS SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CASE IH SPECS

CASE IH SPECS J.I. CASE SPECS

J.I. CASE SPECS PROBLEMS

PROBLEMS LOADERS

LOADERS FARMALL 110A

FARMALL 110A FARMALL 120A

FARMALL 120A FARMALL 30C

FARMALL 30C FARMALL 75C

FARMALL 75C MAGNUM 280

MAGNUM 280 580E Backhoe

580E Backhoe 580L Backhoe

580L Backhoe 580N Backhoe

580N Backhoe 580 Super L

580 Super L 580SM Backhoe

580SM Backhoe 580SLE Backhoe

580SLE Backhoe 580SN Backhoe

580SN Backhoe 580M Backhoe

580M Backhoe 580 Super E

580 Super E 580ST Backhoe

580ST Backhoe MAGNUM 310

MAGNUM 310 MAGNUM 340

MAGNUM 340 MAXXUM 110CVX

MAXXUM 110CVX MAXXUM 120CVX

MAXXUM 120CVX MAXXUM 125

MAXXUM 125 1394

1394 1455XL

1455XL 1494

1494 1594

1594 3230

3230 4210

4210 585XL

585XL 633

633 695XL

695XL 733

733 MX110

MX110 MX135

MX135 MX150

MX150 MXU110

MXU110 MXU135

MXU135 PUMA 175CVX

PUMA 175CVX PUMA 185CVX

PUMA 185CVX PUMA 200CVX

PUMA 200CVX PUMA 240CVX

PUMA 240CVX OPTUM 300

OPTUM 300 FARMALL 50B

FARMALL 50B FARMALL 95U

FARMALL 95U FARMALL 125A

FARMALL 125A PUMA 150

PUMA 150 PUMA 165

PUMA 165 MAGNUM 210

MAGNUM 210 MX 170

MX 170 MAXXUM 150

MAXXUM 150 OPTUM 270

OPTUM 270 MAGNUM 315

MAGNUM 315 FARMALL 70

FARMALL 70 FARMALL 75N

FARMALL 75N FARMALL 95C

FARMALL 95C FARMALL 105N

FARMALL 105N FARMALL 30B

FARMALL 30B L103 Loader

L103 Loader L104 Loader

L104 Loader L105 Loader

L105 Loader L106 Loader

L106 Loader L107 Loader

L107 Loader L108 Loader

L108 Loader L130 Loader

L130 Loader L160 Loader

L160 Loader L300 Loader

L300 Loader L340 Loader

L340 Loader L350 Loader

L350 Loader L360 Loader

L360 Loader L530 Loader

L530 Loader L540 Loader

L540 Loader L545 Loader

L545 Loader L550 Loader

L550 Loader L555 Loader

L555 Loader L560 Loader

L560 Loader L565 Loader

L565 Loader L570 Loader

L570 Loader L575 Loader

L575 Loader L720 Loader

L720 Loader L730 Loader

L730 Loader L735 Loader

L735 Loader L740 Loader

L740 Loader LRZ 95

LRZ 95 LRZ 100

LRZ 100 LRZ 120

LRZ 120 LRZ 130

LRZ 130 LRZ 150

LRZ 150 L745 Loader

L745 Loader L750 Loader

L750 Loader L755 Loader

L755 Loader L760 Loader

L760 Loader L765 Loader

L765 Loader L770 Loader

L770 Loader L775 Loader

L775 Loader L780 Loader

L780 Loader L785 Loader

L785 Loader L795 Loader

L795 Loader 90 Loader

90 Loader 890 Loader

890 Loader 2200 Loader

2200 Loader 2250 Loader

2250 Loader LX156 Loader

LX156 Loader