________________________________________________________________________________

Hydraulic Pump of Case IH 385, 585 Tractor Steering System

Case 385, 585 Tractors may be equipped with either Sun-strand or Plessy

hydraulic gear type pumps. The maximum pump output is controlled by

engine rpm and the number of teeth on the pump drive gear.

The priority flow divider sends approximately 3 gpm to the steering

system and the balance is used for the draft and position controls on

the hitch lift system and for the auxiliary control valves.

Overhaul

To remove the hydraulic pump, first drain all compartments of Hy-Tran

Plus fluid. Although the pump can be removed with left rear wheel

Installed, most mechanics prefer to remove left rear wheel to provide

more room to remove the multiple control valve and pump assembly.

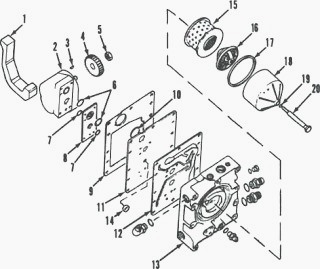

Fig.9

Thoroughly clean the area around the multiple control valve, then remove

the hydraulic filter assembly (15 through 20—Fig, 9).

Disconnect steering lines, oil cooler line, hitch supply line, auxiliary

valves return line and pto line from multiple control valve (13).

Immediately cap or plug all openings. On models equipped with XL cab,

remove left console.

On Case IH 585, 385 Tractor, disconnect and remove park brake warning

switch wires and linkage. Disconnect and remove pto operating lever.

Remove two cap screws from opposite sides of multiple control valve.

Install two 3/8 x 5 inch guide studs in the holes to aid in removal and

installation of the assembly. Remove the balance of the retaining cap

screws, then slide multiple control valve outward from rear main frame.

Lay the assembly on a clean bench. Remove the four cap screws and copper

washers, then lift off hydraulic pump assembly (2) and spacer plate (8),

if so equipped.

Spacer plate (8) is used only on Case 385, 585 Tractor equipped with a

23 tooth pump drive gear.

Disassembly of the pump is obvious after examination of the unit. Remove

nut (5), drive gear (4) and Woodruff key (3). Remove end plate cap

screws and separate pump components.

Clean and inspect all parts. If any parts show excessive wear or other

damage, renew pump assembly. A seal kit is available for resealing the

pump.

When reassembling pump, tighten end plate cap screws to a torque of

20-23 ft .-lbs. (27-31 N-m). Install Woodruff key (3), place drive gear

(4) on shaft and install and tighten nut (5) to a torque of 45-50

ft.-lbs. (61-68 Nm).

Hold drive gear in a vise while tightening nut. Check condition of foam

seal (1). If damaged or loose, remove and discard seal. Clean seal area

with a rag and adhesive solvent, then dry the housing.

Apply a thin coat of oil resistant adhesive to the housing and to a new

foam seal. Let adhesive dry one to two minutes, then install foam seal

on pump housing. Allow adhesive to dry at least another 30 minutes

before installing pump assembly.

When reassembling, use all new "O" rings, seal ring and gaskets. Install

pump and spacer (8), if so equipped, to multiple control valve. Use new

copper washers on the four pump retaining cap screws. Install and

tighten cap screws to a torque of 18-24 ft.-lbs. (24-28 N-m).

Lubricate foam seal (1) with Hy-Tran Plus fluid and reinstall multiple

control valve and pump assembly by reversing the removal procedure.

Tighten multiple control valve retaining cap screws to a torque of 33-37

ft.-lbs. (45-50 N-m).

Reinstall hand park brake linkage and pto linkage. Then, using a new

filter element (15), "o" rings and gasket, install hydraulic filter

assembly. Tighten filter center bolt to a torque of 12-16 ft.-lbs.

(16-21 N-m).

Connect all disconnected hydraulic lines. Fill transmission to correct

level on dipstick with Hy-Tran Plus oil. Refill capacity is 36 U.S.

quarts (34.0 L) on tractors without front drive axle and 38.6 U.S.

quarts (36.5 L) on tractors with front drive axle.

Case IH 385, 585 Tractor Hydraulic

pump test

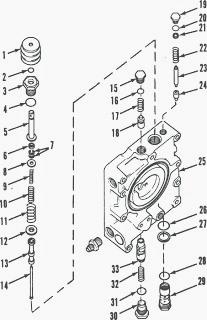

Fig.10

To check flow and pressure of the hydraulic pump, first remove the plug

(Fig. 10) for the flow divider. Remove spring (32) and spool (33), then

reinstall plug. Remove the pilot relief valve (29) and install a test

pilot relief valve.

Disconnect the power steering supply pipe (directly below hydraulic

filter). Cap the pipe and union on multiple control valve with high

pressure caps. Disconnect hitch supply line (bottom rear line on

multiple control valve) and cap the line.

Connect the inlet hose from the flowmeter to the hitch supply union on

the multiple control valve. Place outlet hose from flowmeter into

transmission oil fill hole and wire in place. Fully open load valve on

flowmeter.

Start Case 385, 585 Tractor engine and operate at a speed of 2180 rpm.

Record the flow. Close load control valve to obtain a reading of 2000

psi (13790 kPa) on pressure gage, then record the flow.

Fully open the load valve and stop engine. The second flow reading must

not be less than 90 percent of the first flow reading. If second reading

is too low, check for the following conditions: Low oil level, Clogged

filter, Faulty pump.

Remove test pilot relief valve and using new seal rings, install

original pilot relief valve. Remove flow divider plug (30) and install

spool (33) and spring (32). Reinstall and tighten plug.

Remove caps from steering supply line and union, then connect steering

line. Disconnect and remove flowmeter and connect hitch supply line.

Start tractor and bleed air from steering system.

________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH TRACTORS SPECIFICATIONS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

| CASE IH FRONT END LOADERS SPECS |

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

CASE IH SPECS

CASE IH SPECS J.I. CASE SPECS

J.I. CASE SPECS PROBLEMS

PROBLEMS LOADERS

LOADERS FARMALL 110A

FARMALL 110A FARMALL 120A

FARMALL 120A FARMALL 30C

FARMALL 30C FARMALL 75C

FARMALL 75C MAGNUM 280

MAGNUM 280 580E Backhoe

580E Backhoe 580L Backhoe

580L Backhoe 580N Backhoe

580N Backhoe 580 Super L

580 Super L 580SM Backhoe

580SM Backhoe 580SLE Backhoe

580SLE Backhoe 580SN Backhoe

580SN Backhoe 580M Backhoe

580M Backhoe 580 Super E

580 Super E 580ST Backhoe

580ST Backhoe MAGNUM 310

MAGNUM 310 MAGNUM 340

MAGNUM 340 MAXXUM 110CVX

MAXXUM 110CVX MAXXUM 120CVX

MAXXUM 120CVX MAXXUM 125

MAXXUM 125 1394

1394 1455XL

1455XL 1494

1494 1594

1594 3230

3230 4210

4210 585XL

585XL 633

633 695XL

695XL 733

733 MX110

MX110 MX135

MX135 MX150

MX150 MXU110

MXU110 MXU135

MXU135 PUMA 175CVX

PUMA 175CVX PUMA 185CVX

PUMA 185CVX PUMA 200CVX

PUMA 200CVX PUMA 240CVX

PUMA 240CVX OPTUM 300

OPTUM 300 FARMALL 50B

FARMALL 50B FARMALL 95U

FARMALL 95U FARMALL 125A

FARMALL 125A PUMA 150

PUMA 150 PUMA 165

PUMA 165 MAGNUM 210

MAGNUM 210 MX 170

MX 170 MAXXUM 150

MAXXUM 150 OPTUM 270

OPTUM 270 MAGNUM 315

MAGNUM 315 FARMALL 70

FARMALL 70 FARMALL 75N

FARMALL 75N FARMALL 95C

FARMALL 95C FARMALL 105N

FARMALL 105N FARMALL 30B

FARMALL 30B L103 Loader

L103 Loader L104 Loader

L104 Loader L105 Loader

L105 Loader L106 Loader

L106 Loader L107 Loader

L107 Loader L108 Loader

L108 Loader L130 Loader

L130 Loader L160 Loader

L160 Loader L300 Loader

L300 Loader L340 Loader

L340 Loader L350 Loader

L350 Loader L360 Loader

L360 Loader L530 Loader

L530 Loader L540 Loader

L540 Loader L545 Loader

L545 Loader L550 Loader

L550 Loader L555 Loader

L555 Loader L560 Loader

L560 Loader L565 Loader

L565 Loader L570 Loader

L570 Loader L575 Loader

L575 Loader L720 Loader

L720 Loader L730 Loader

L730 Loader L735 Loader

L735 Loader L740 Loader

L740 Loader LRZ 95

LRZ 95 LRZ 100

LRZ 100 LRZ 120

LRZ 120 LRZ 130

LRZ 130 LRZ 150

LRZ 150 L745 Loader

L745 Loader L750 Loader

L750 Loader L755 Loader

L755 Loader L760 Loader

L760 Loader L765 Loader

L765 Loader L770 Loader

L770 Loader L775 Loader

L775 Loader L780 Loader

L780 Loader L785 Loader

L785 Loader L795 Loader

L795 Loader 90 Loader

90 Loader 890 Loader

890 Loader 2200 Loader

2200 Loader 2250 Loader

2250 Loader LX156 Loader

LX156 Loader